Double-plug piping method of heavy-caliber gas exhaust hole working sleeve

A gas pumping and large-diameter technology, which is applied in gas discharge, drilling equipment and methods, and earthwork drilling and production, can solve the problems of small load capacity of drilling rigs, large lateral pressure of empty pipes, long empty pipes, etc., and reduce risks The effect of reducing the internal and external pressure difference and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

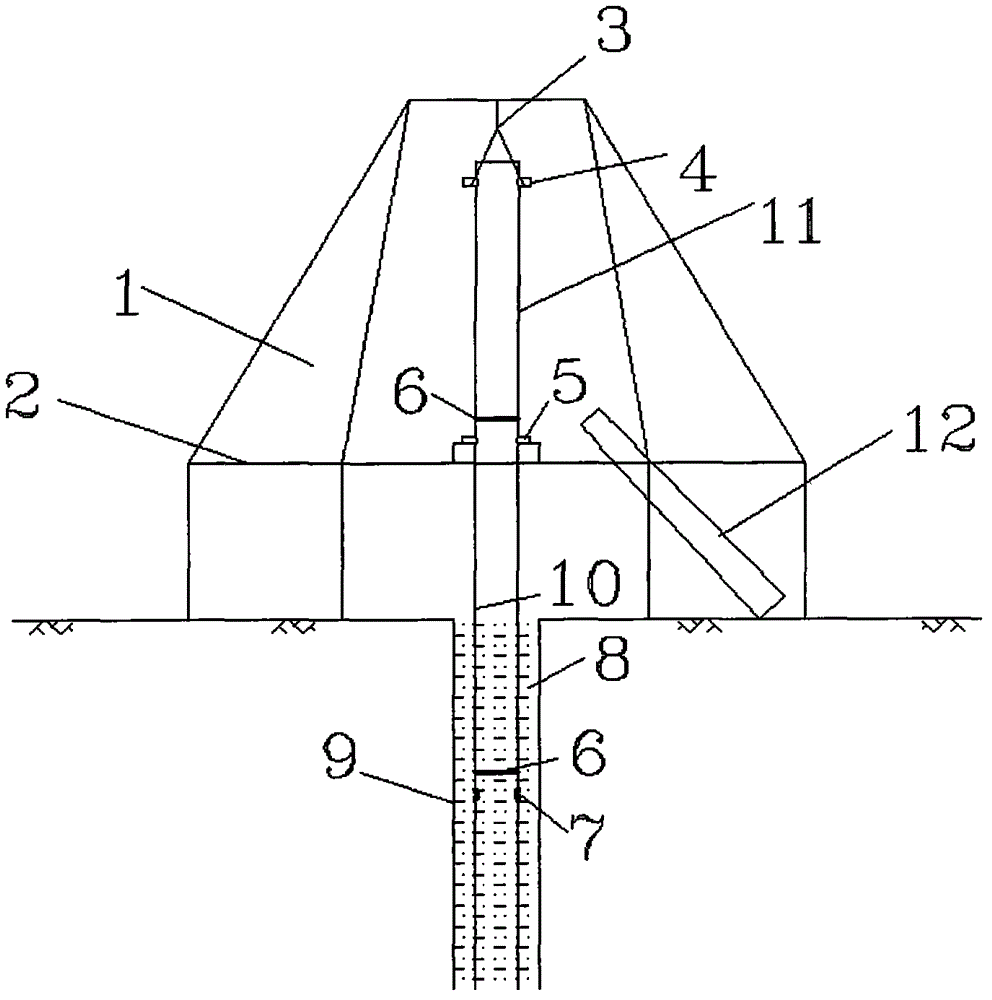

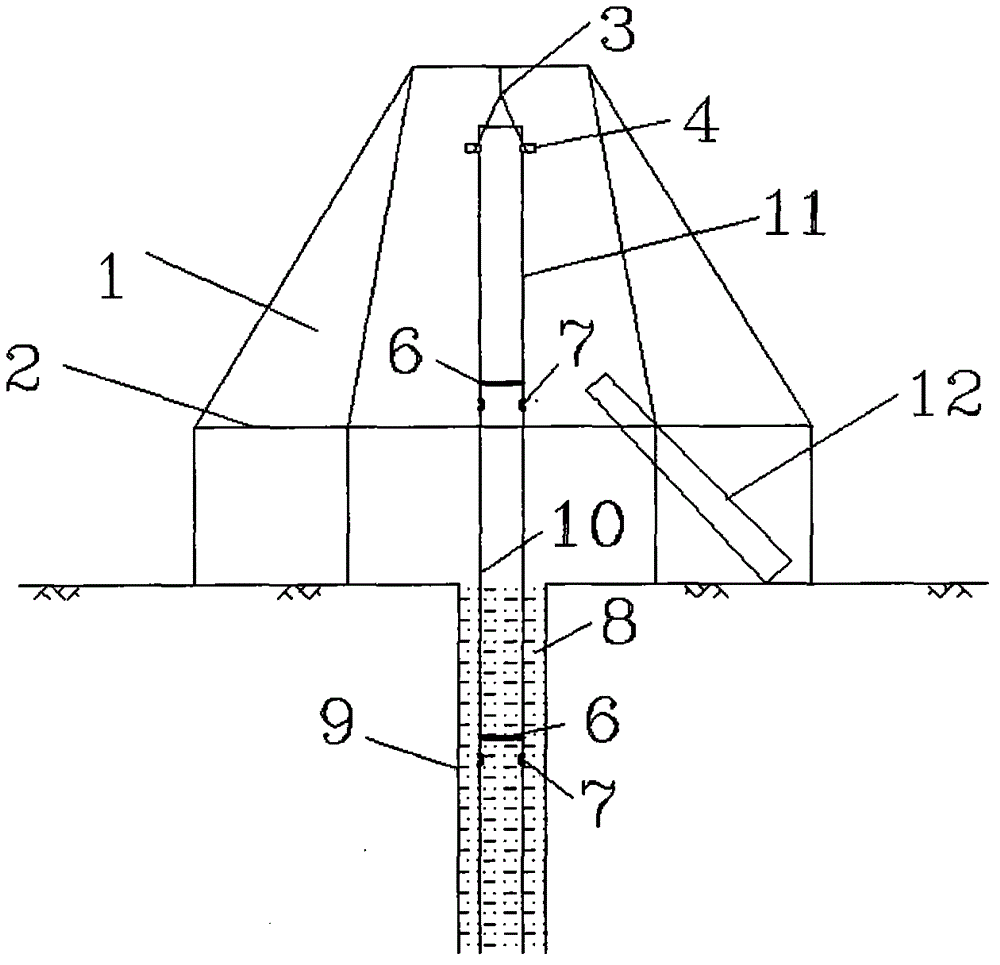

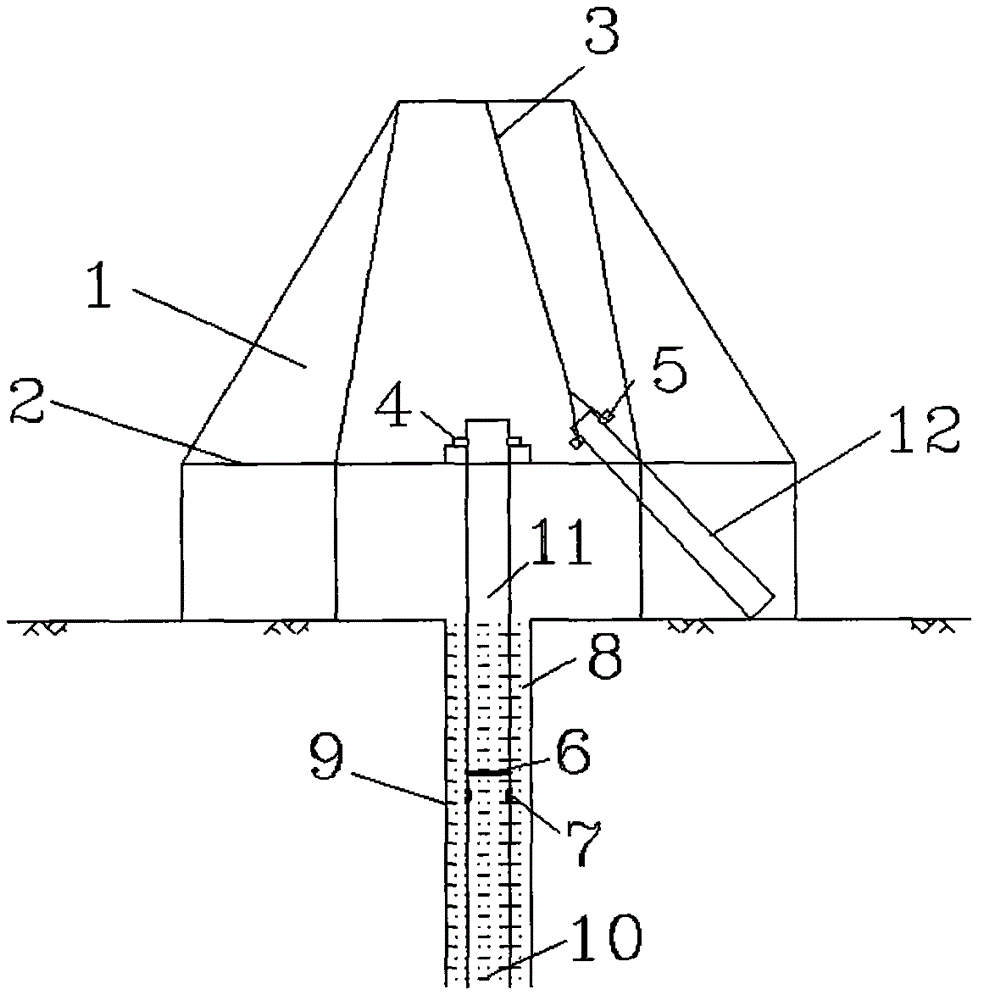

[0049] In order to further illustrate the technical solution of the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0050] Project overview: Drill hole 9 has a depth of 816m and a hole diameter of 790mm. It is designed to use a working casing with an outer diameter of 630mm and a thickness of 18mm. The material of the working casing is steel with a density of 7.8t / m 3 , the buoyancy plug 14 and the buoyancy valve 15 weigh 10 tons in total and have a total mass of 230 tons. According to engineering practice experience, the design safety length of the empty pipe of the working casing is 220m. The specific gravity of mud 8 is 1.15t / m 3 . like Figure 4 shown.

[0051] According to the known engineering situation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com