Oil filter assembly

An oil filter and filter technology, which is applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of easy wear of sealing rings, buried fault hidden dangers, and high risk of failure, etc. Problems, to achieve the effect of increasing strength, prolonging service life, ensuring stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

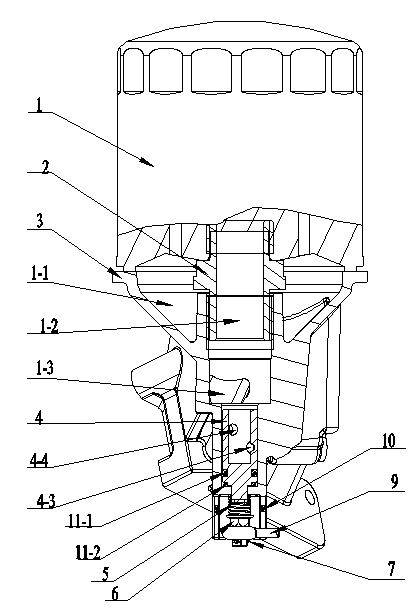

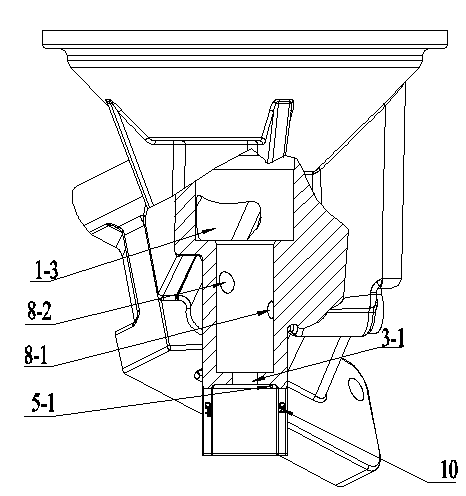

[0039] figure 1 , figure 2 What is shown is a schematic structural diagram of this embodiment, including a filter 1 , and the filter 1 is arranged on a mounting base 3 through a connecting pipe 2 .

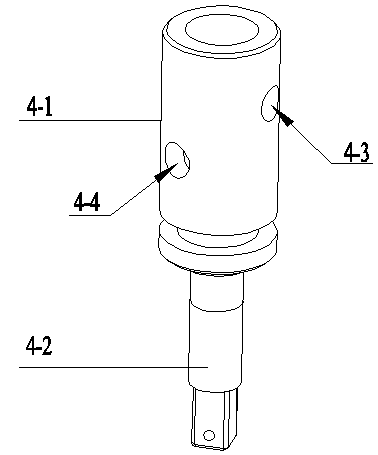

[0040] The filter oil inlet chamber 1-1 is used to connect with the oil outlet of the oil pump, and the filter oil outlet chamber 1-2 is connected with the main oil passage of the engine through the filtered oil outlet 1-3 (There is no oil return device between the filtered oil outlet 1-3 and the filter oil outlet chamber 1-2, and the oil return device does not form a flow resistance), the filtered oil outlet 1-3 is set on the installation The upper part of the seat 3, the lower part of the mounting seat 3 is provided with an oil return device 4 for oil return and an oil return control device for supporting and controlling the oil return device for oil return. The oil return device 4 is not It is in contact with the filter 1; when the filter assembly is disassembled, the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com