Method for improving lubricating property of linear contact fluid under high roll ratio

A technology of fluid lubrication and contact body, which is applied in the field of worm gear transmission and gear transmission, which can solve the problems of failure of lubricating oil film in the contact area, decrease of lubricating oil viscosity, and high frictional energy consumption in the contact area, so as to improve the surface anti-adhesion ability and improve Lubrication state, effect of reducing frictional energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

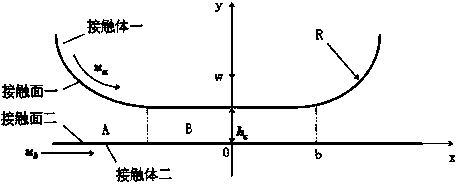

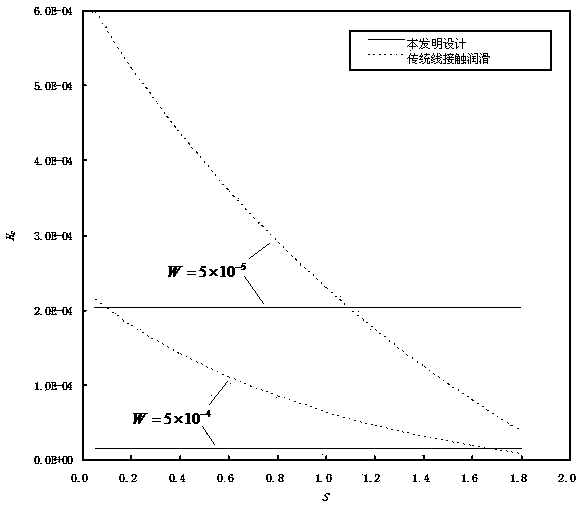

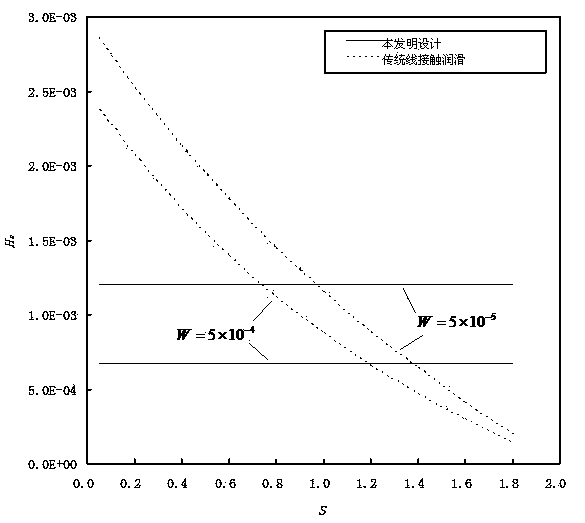

[0034] Such as figure 1 As shown, the present invention discloses a method for improving the lubrication of a contact fluid with a large slip-roll ratio. It is assumed that a cylindrical contact body 1 forms a line contact with a flat contact body 2, and the peripheral speed of the contact body 1 is greater than that of the contact body 2. linear velocity of motion, apply a load that makes the maximum hertz contact pressure not less than 0.5GPa in the linear contact area between the contact body 1 and the contact body 2, and coat the surface of the contact body 1 with an oleophilic coating, the The outer surface of the oleophilic coating is the first contact surface, and the surface of the second contact body is coated with an oleophobic coating, the outer surface of the oleophobic coating is the second contact surface, and the two contact surfaces are filled with lubricating oil , the interfacial shear strength between contact surface 1 and lubricating oil is greater than tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com