Optical waveguide structure of photoelectric detector for vertical coupling

A vertical coupling, photodetector technology, applied in the direction of light guides, instruments, circuits, etc., to achieve the effects of low coupling loss, low coupling loss, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

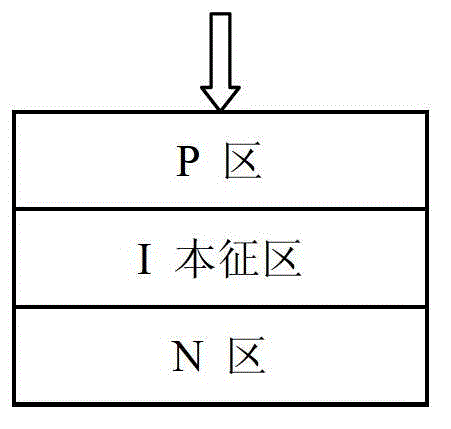

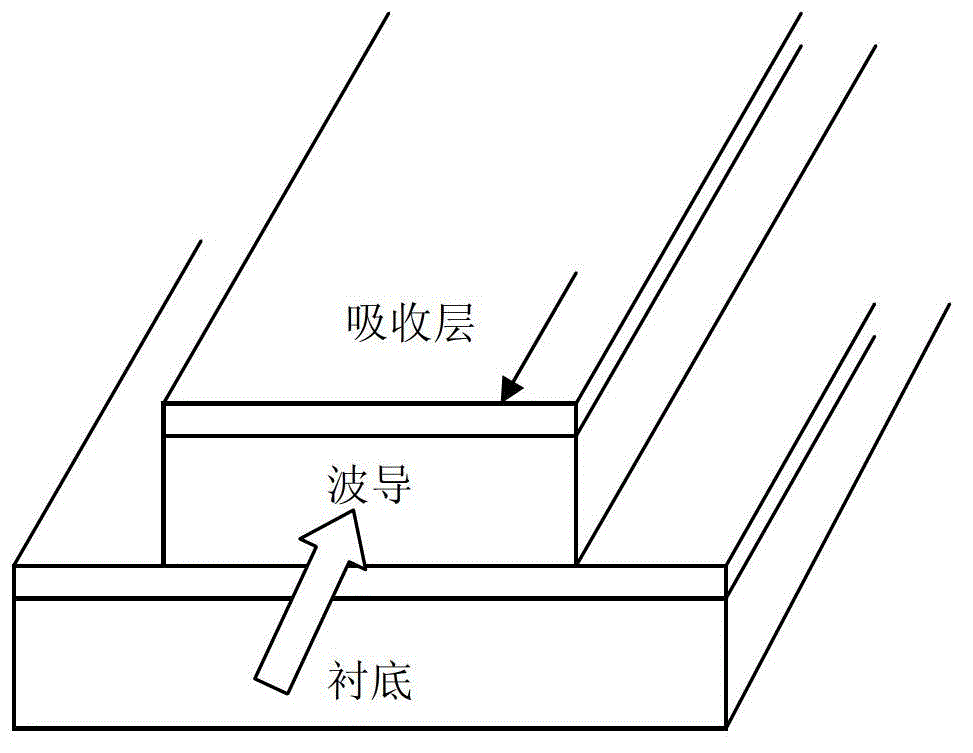

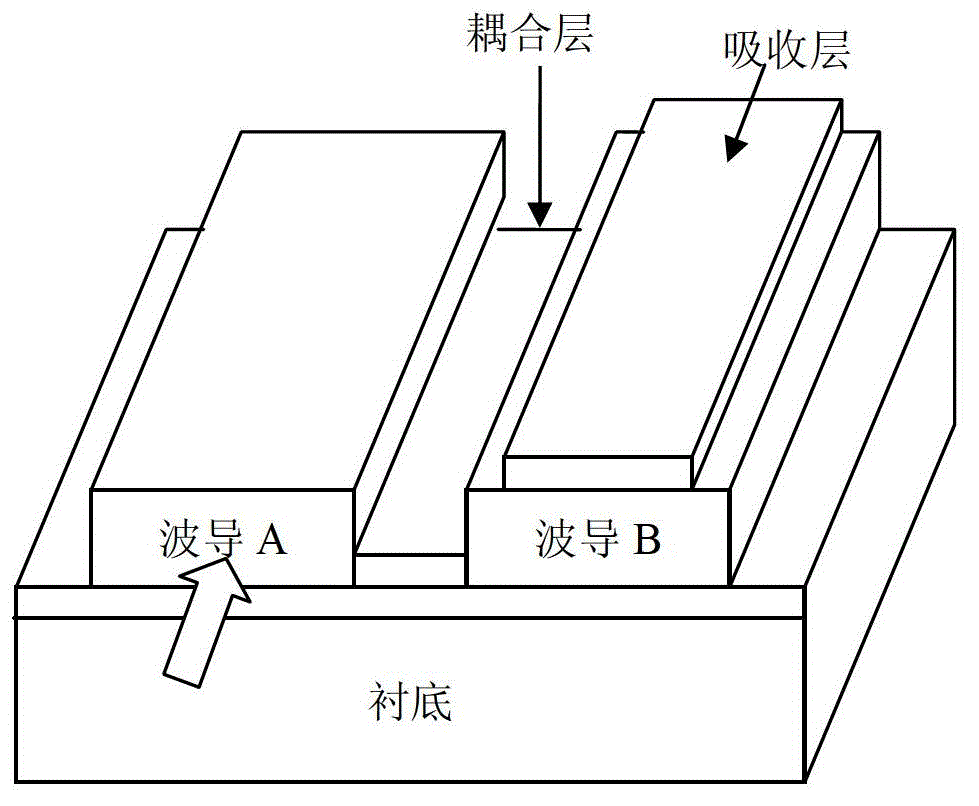

[0017] Such as Figure 4 and 5 As shown, the optical waveguide structure of the photodetector for coupling in the vertical direction includes an intrinsic layer 1, an absorbing layer 2, an upper waveguide layer 3, a gap layer 4, a lower waveguide layer 5, and a cover layer stacked sequentially from top to bottom 6 and a substrate 7, the gap layer 4 is used as a low-refractive-index coupling layer between the upper waveguide layer 3 and the lower waveguide layer 5, and the upper waveguide layer 3 and the lower waveguide layer 5 form a coupler in the vertical direction (equivalent to a photodiode coupled in the vertical direction) is used to make the light incident from the lower waveguide layer 5 gradually coupled to the upper waveguide layer 3 and make the light be absorbed by the absorption layer 2 while being transmitted in the upper waveguide lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com