Novel steam turbine generator cooling system

A steam turbine generator and cooling system technology, which is applied to cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems that the inlet air temperature of the air cooler cannot meet the safe operation requirements of the generator set, and the generator air temperature is high. Achieve high engineering application value and social and economic significance, save water and energy, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

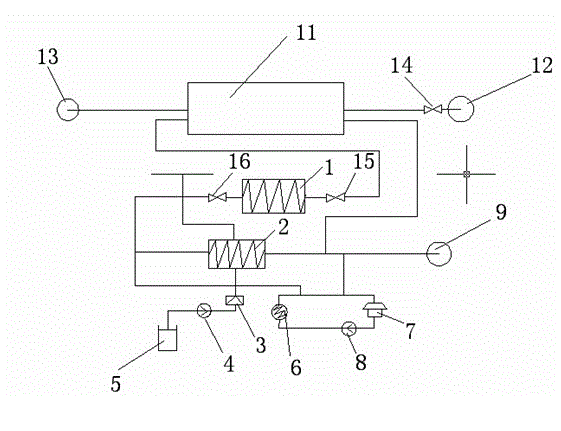

[0012] Such as figure 1 As shown, the turbogenerator cooling system of the present invention includes an internal cooling circulating cooling system and an external cooling refrigerant water heat exchanger 11, and the internal cooling circulating cooling system includes an air cooler 1, an oil cooler 2, Check valve 3, oil pump 4, oil tank 5, condenser 6, cooling tower 7, circulation pump 8, industrial water supply port 9. The two ends of the air cooler 1 and the oil cooler 2 are respectively connected, the two ends of the condenser 6 and the cooling tower 7 are respectively connected, the lower end of the cooling tower 7 is connected with a circulation pump 8, and one end of the oil cooler 2 is connected with an industrial water inlet 9, The other end is connected to the circuit in which the condenser 6 communicates with the cooling tower 7 . The lower end of the oil cooler 6 is provided with a check valve 3 , and the lower end of the check valve 3 is provided with an oil pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com