Self-turnoff component driving protection circuit

A drive protection circuit, self-shutdown technology, applied in the field of power electronics, can solve the problems of long shutdown time, low overcurrent capability, low sensitivity, etc., to suppress overvoltage and oscillation, achieve desaturation protection, and ideal waveform stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

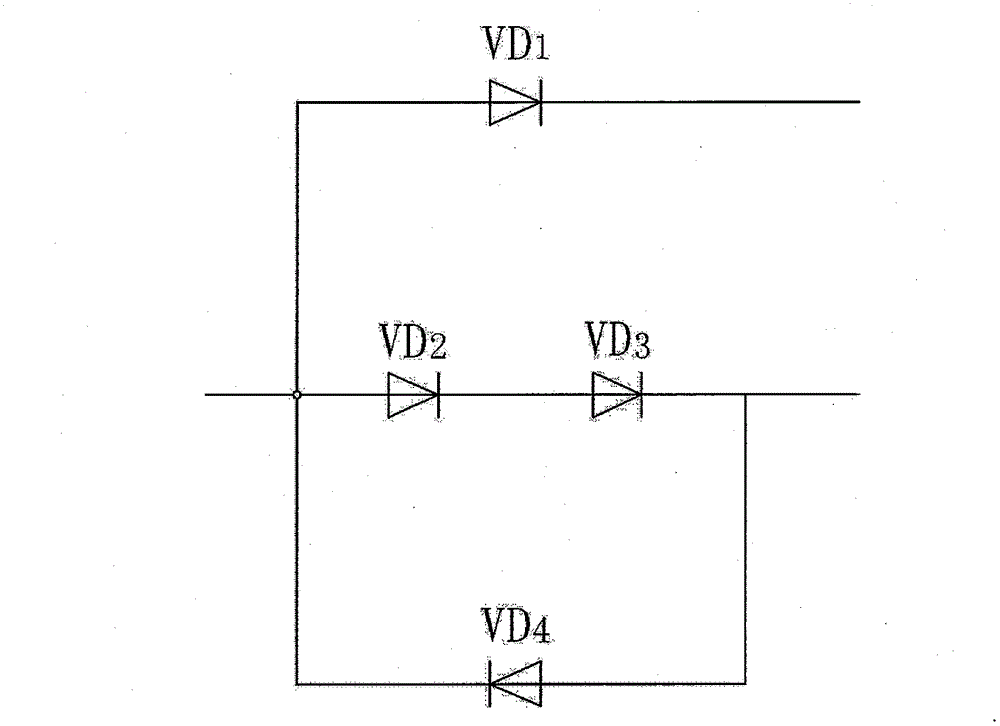

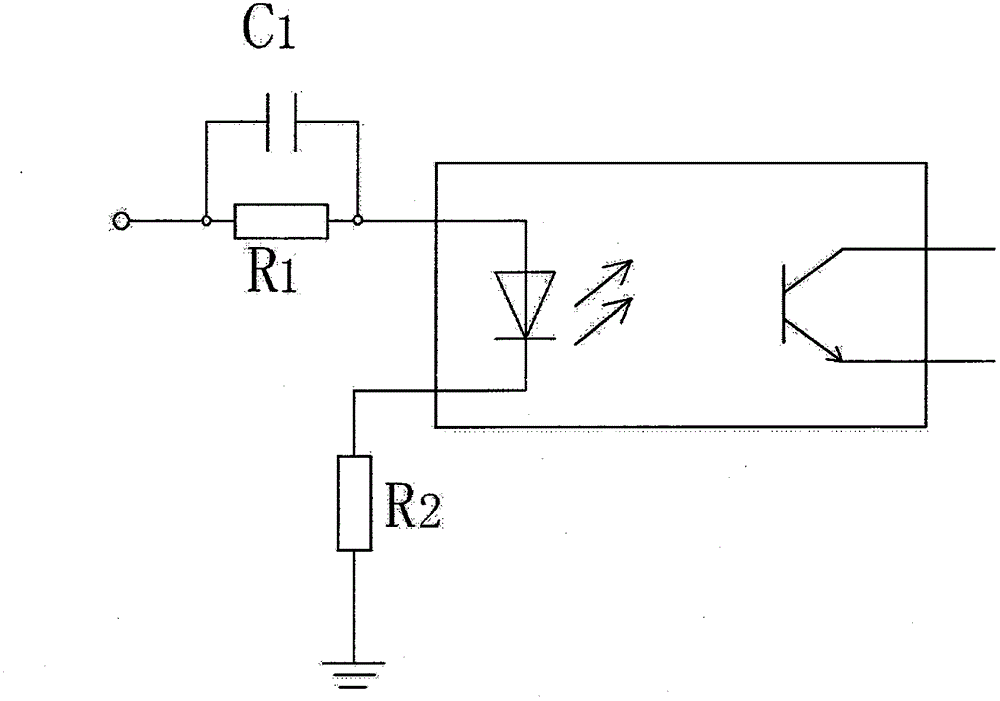

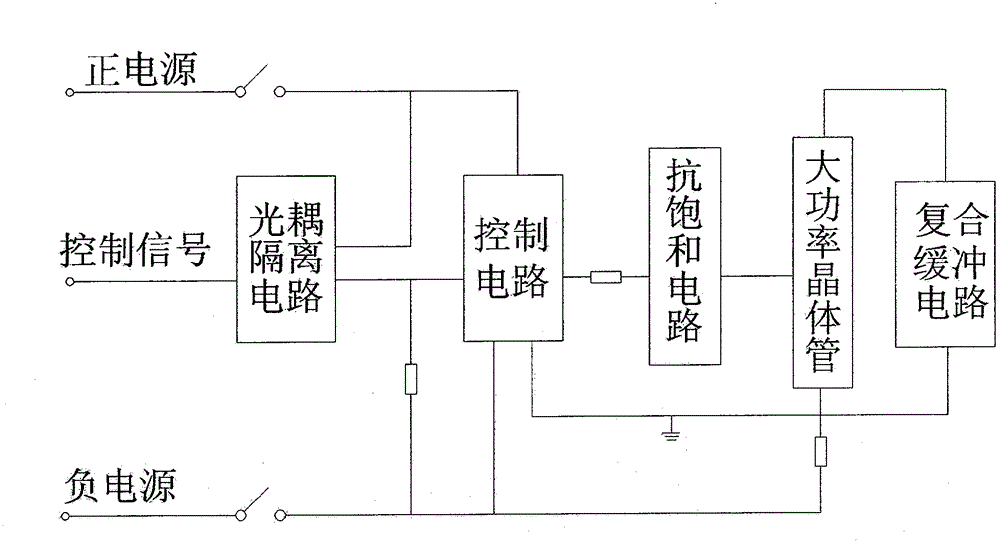

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a positive and negative power supply, an optocoupler isolation circuit, a control circuit, an anti-saturation circuit, a high-power transistor, and a composite buffer circuit.

[0019] The control signal of the circuit is filtered by R1 and C1 and then input to the anode of the primary light-emitting diode of the optocoupler O1, the negative pole of the light-emitting diode is grounded through the resistor R2, and the emitter of the secondary phototransistor of the optocoupler O1 is directly connected to the chip in the control circuit The input terminal of UAA4002 is connected to the negative power supply -Vcc through resistor R3 and switch S2, and the positive power supply Vcc is connected to the collector of the phototransistor through switch S1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com