Sub-soiling tillage at different times

A deep loosening and soil technology, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of increasing fuel consumption, easy slipping, easy to run moisture, etc., to reduce power consumption for site preparation, improve soil moisture content, and operate Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

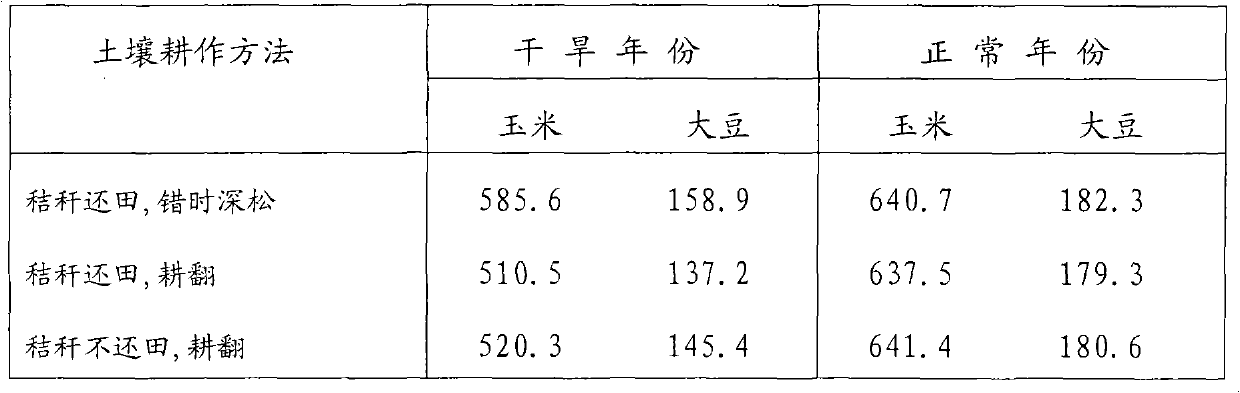

[0007] Embodiment: Take corn stalks as an example.

[0008] (1) After the corn is harvested in autumn, the straw is mechanically crushed and thrown to cover the surface of the ridge-cropped land. The length of the crushed straw is less than 20cm, the crushing rate of the straw is greater than 90%, and the height of the stubble is less than 10cm;

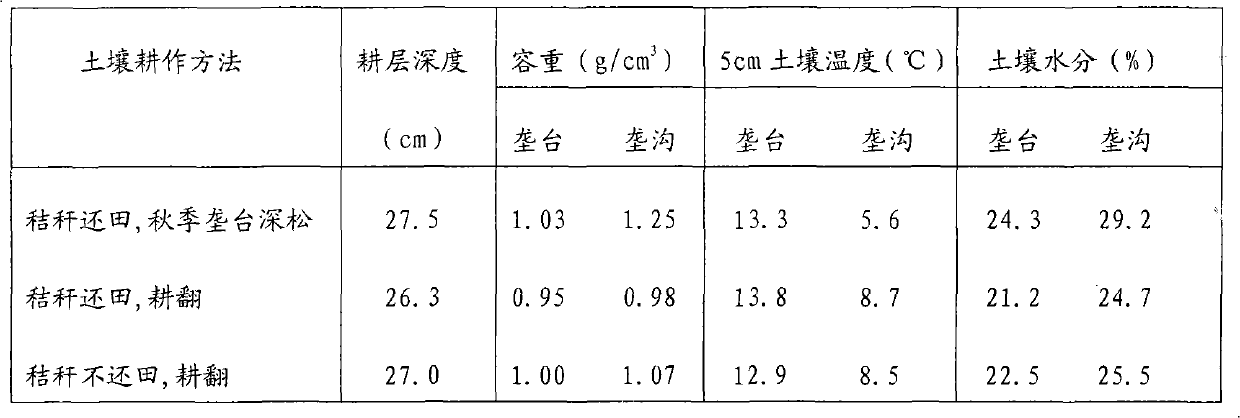

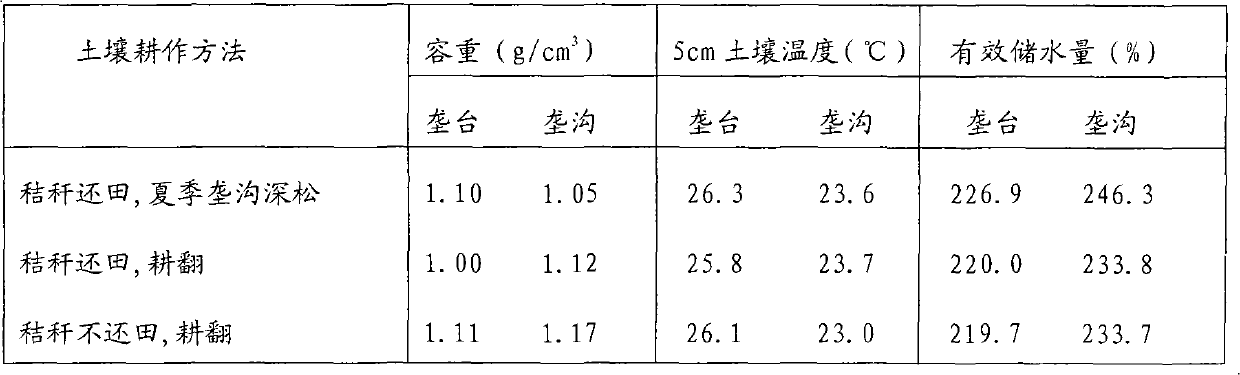

[0009] (2) In autumn, carry out subsoiling on the ridge platform, and the subsoiling depth is 25-30cm; at the same time, carry out stubble removal along the subsoiling position of the ridge platform, with a stubble removal width of 24-32cm and a depth of 7-8cm;

[0010] (3) In the spring of the second year, after sowing along the subsoiling and stubble removal belt, subsoiling in furrows is carried out when the crops have 3-4 leaves at the seedling stage, and the subsoiling depth is 20-30cm.

[0011] When crops are harvested, most of the straw crushed and scattered in the ridge area falls into the ridge, and a small part stays on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com