Filtering and drying apparatus for wastes recycling

A technology of filtration drying and resources, applied in sludge drying, filtration loop, filtration separation, etc., to achieve the effect of simple reuse and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

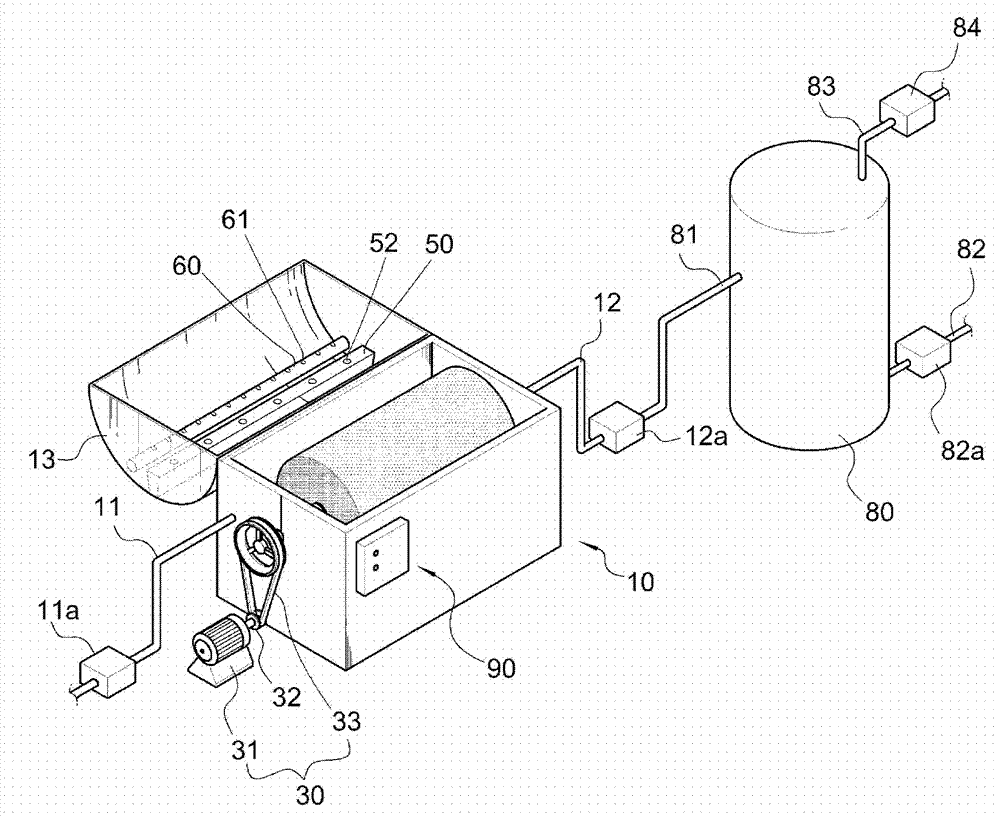

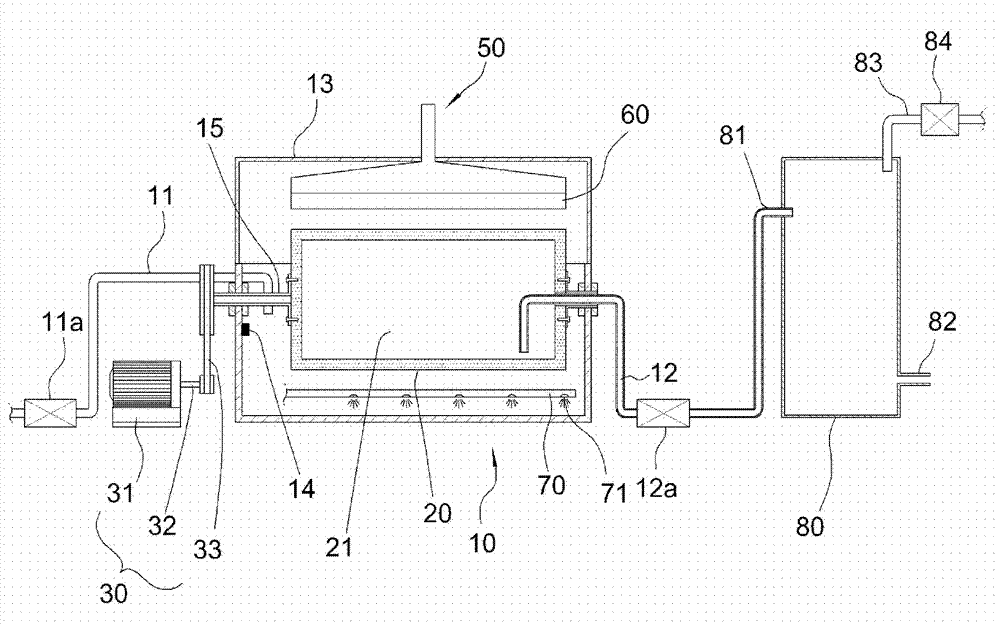

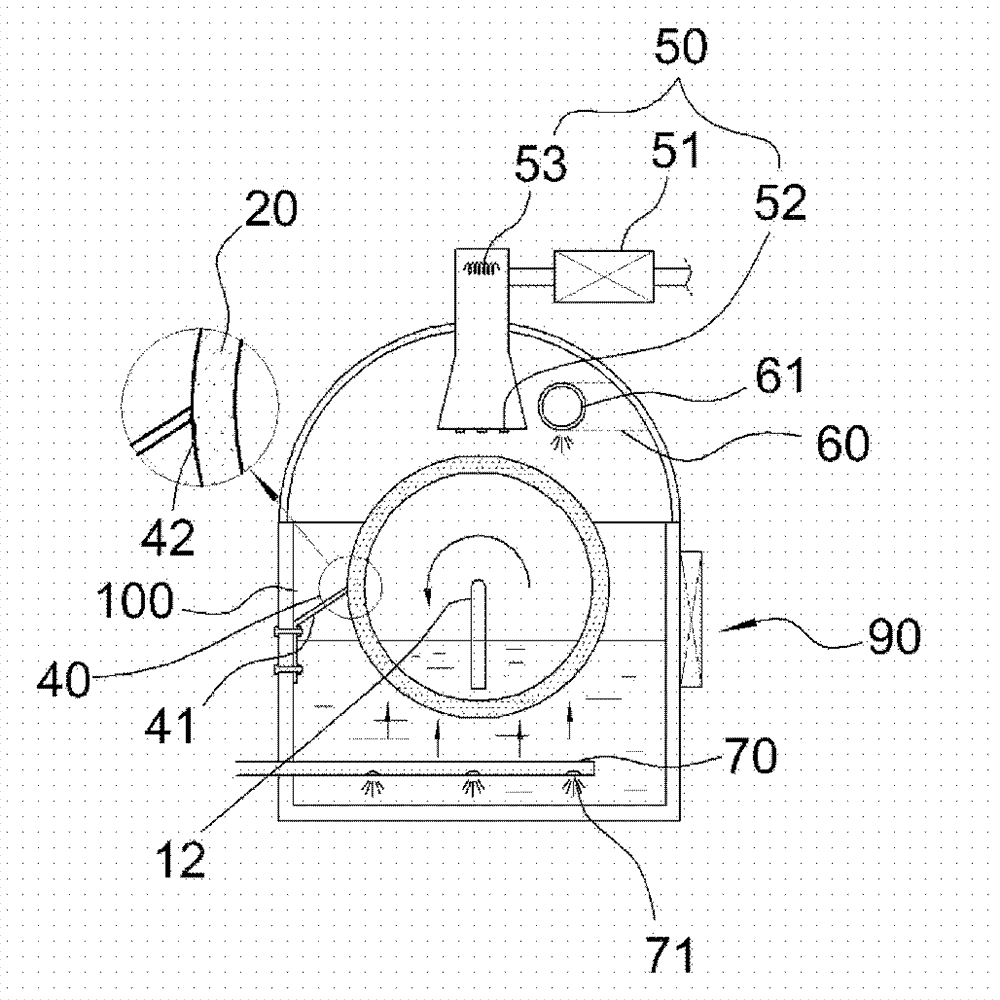

[0053] Hereinafter, the mud and resource reuse filtration and drying device of the present invention will be described in detail with reference to the drawings.

[0054] The mud and resource reuse filtration and drying device of the present invention is generally composed of a processing tank 10, a rotating drum 20, a driving device 30, a stripper 40, a hot air drying device 50, a drum washing device 60, an aeration device 70, and a fine filtration separation device 80 constitute.

[0055] As shown in the figure, the treatment tank 10 is formed in a hollow cylindrical shape to store raw water containing particulate matter to be removed. In addition, a supply pipe 11 connected to a supply pump 11a is connected to one side, and the supply pipe 11 is connected to an unillustrated waste water storage tank or the like so that raw water flows from the outside according to the suction operation of the supply pump 11a.

[0056] On the other hand, a discharge pipe 12 connected to a discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com