Porous ceramic plate photocatalyst carrier

A technology of porous ceramic plates and photocatalysts, applied in the direction of catalyst carriers, biocides, plant growth regulators, etc., can solve the problems of short service life, insufficient adhesion of photocatalyst film, easy to fall off, etc., and achieve long service life and high efficiency photocatalyst Catalytic reaction effect, not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

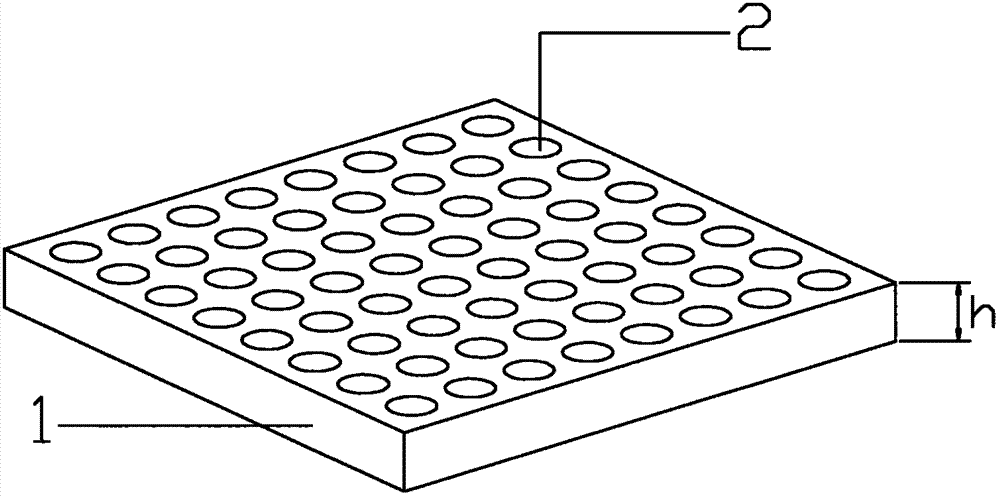

[0014] figure 1 A porous ceramic plate photocatalyst carrier is shown, which can be applied to the field of high-efficiency photocatalytic air purification. It has a ceramic plate 1 body, the material of the ceramic plate 1 is cordierite, the porosity is 45%, the micropore diameter is 2-3 μm, the water absorption rate is at least 25%, and the specific surface area is 5-10 square meters per gram, and The thickness h of the ceramic plate 1 is 5 to 20mm, which can improve the scope of application of the ceramic plate 1; the through holes 2 of the same size are evenly distributed on the ceramic plate 1, in order to increase the irradiation area of the photocatalyst by ultraviolet light and the photocatalyst For the contact area with poisonous and harmful gases, the through holes 2 are circular holes, conical holes or polygonal holes, and the number of ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com