Composite substrate structure

A composite and substrate technology, applied in the field of composite substrate structure, can solve the problems of easy adhesion of oil, peeling of anti-etching layer, insufficient light transmittance and mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0020] The composite substrate structure disclosed in the present invention can be applied to the composition structure of touch panel, liquid crystal panel, optical lens, architectural glass or automobile windshield. In the following embodiments disclosed in the present invention, the composite substrate is used The structure is applied to the touch panel as an example, but not limited thereto.

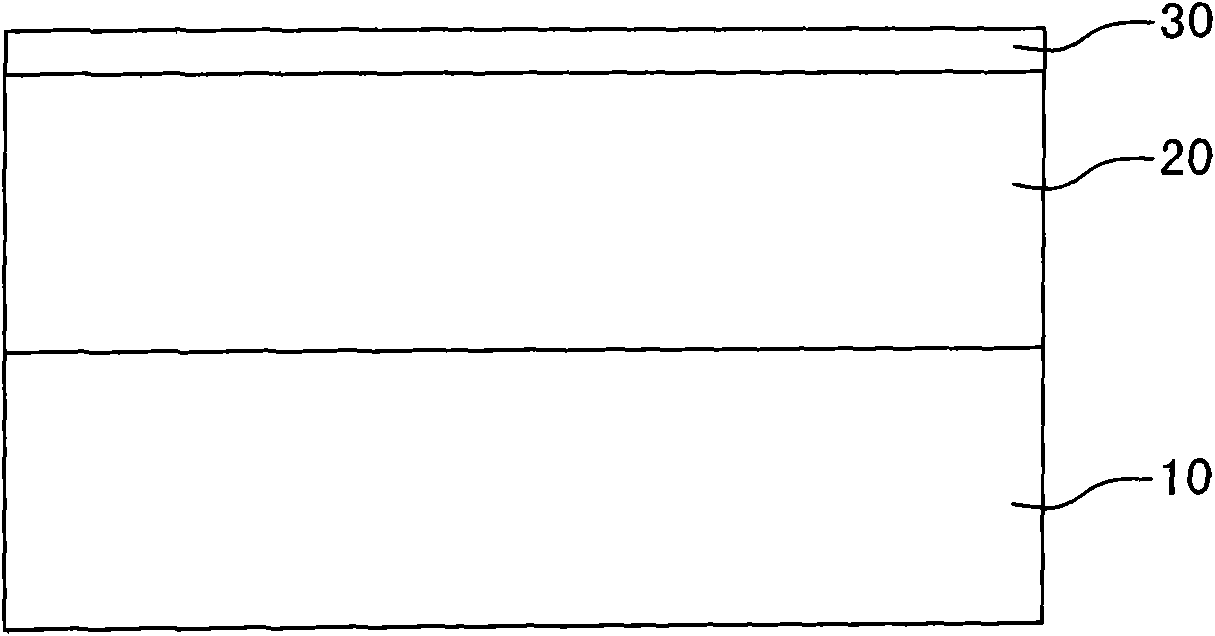

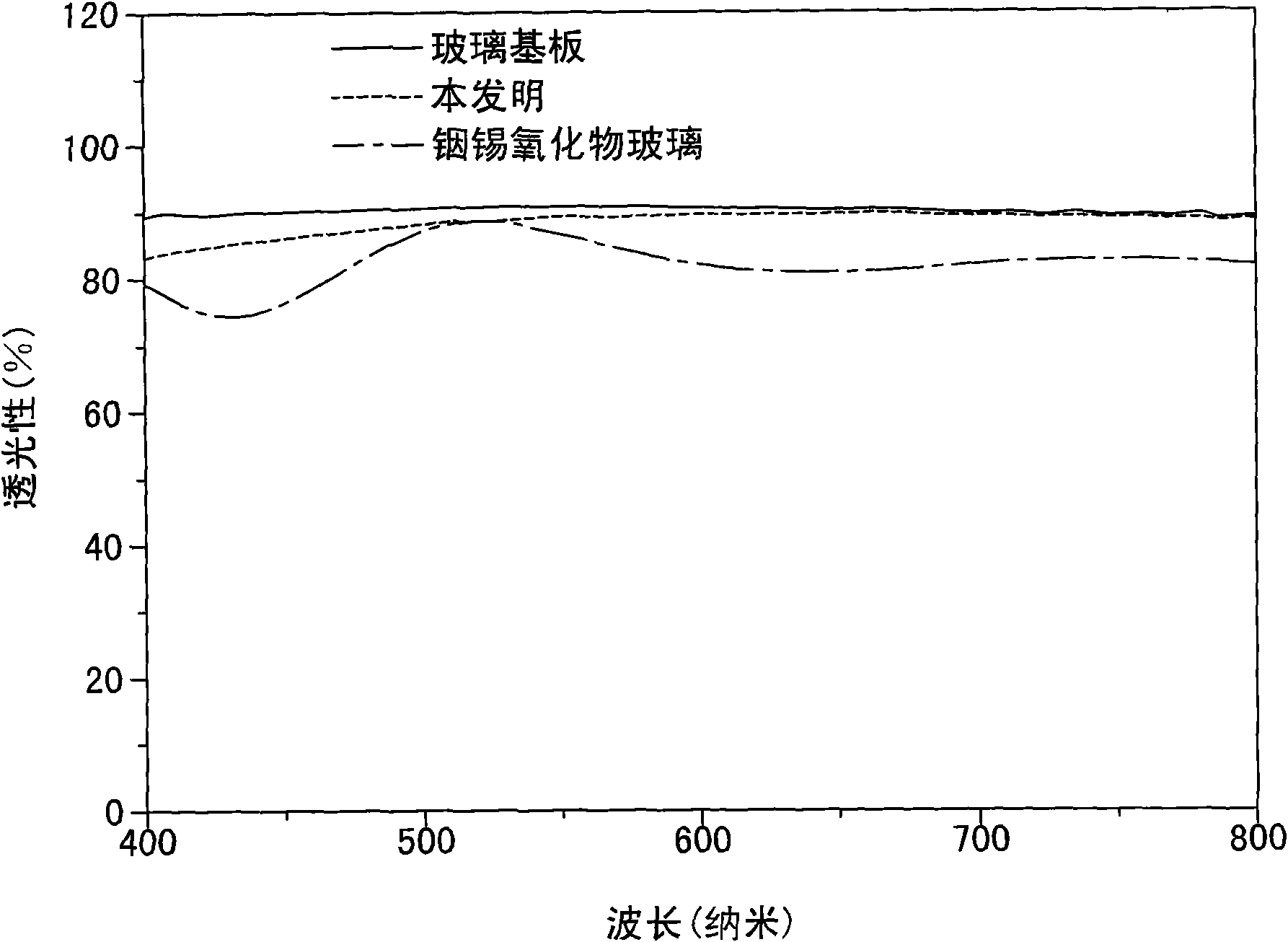

[0021] like figure 1 Shown is the composite substrate structure disclosed in the first embodiment of the present invention, which includes a transparent substrate 10 , a first DLC layer 20 and a second DLC layer 30 . The transparent substrate 10 is made of a material with good light transmittance, and the light transmittance material can be but not limited to glass material or polymer material. The first diamond-like carbon layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com