Aerobat aerodynamic configuration adopting mixing wing body

An aerodynamic shape, hybrid wing body technology, applied in the wing shape, fuselage, wing and other directions, can solve the problems of inability to arrange escape hatches, unfavorable longitudinal balance control, large sweep angle of the outer wing section, etc. Effects of increased structural weight, length, and large sweep angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

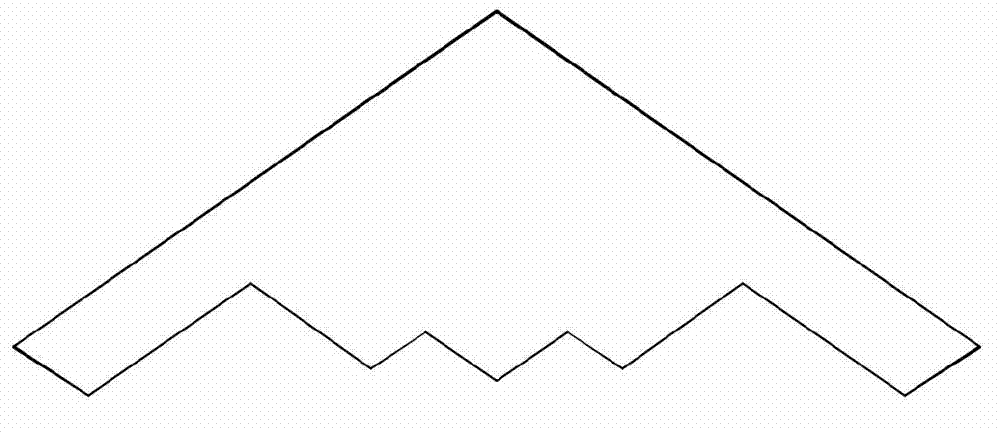

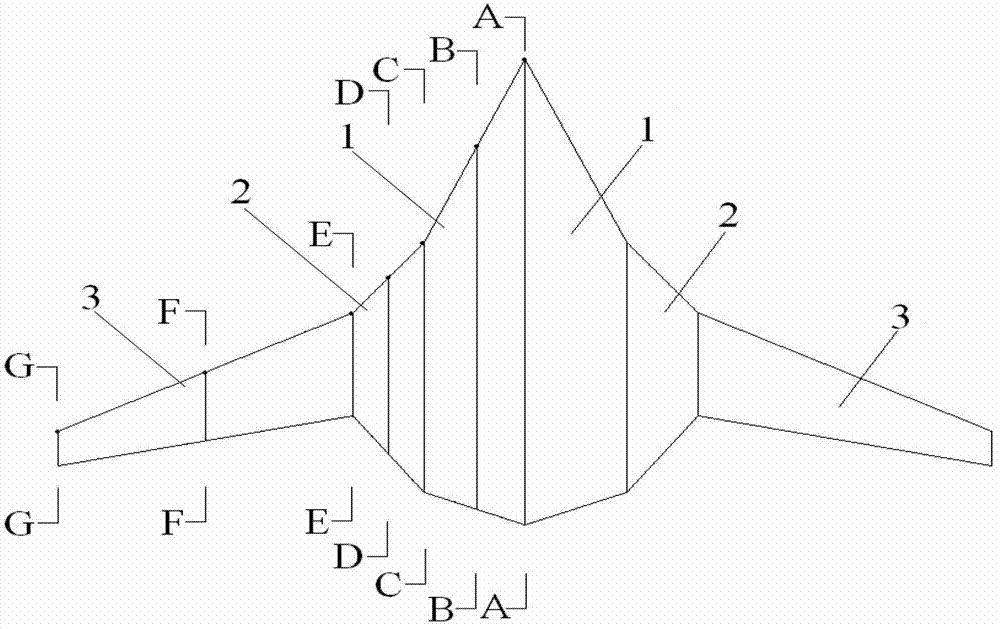

[0071] Present embodiment is a kind of aerodynamic profile that adopts the aircraft of hybrid wing body, as figure 2 As shown, this embodiment takes one side of the fuselage as an example, along the span of the fuselage, there are respectively the central fuselage 1, the transition section 2 and the outer wing section 3, and the transition section 2 is located between the central fuselage 1 and the outer wing section 3 Between them, the area ratio of the central body 1, the transition section 2 and the outer wing section 3 is 1:0.350:0.554.

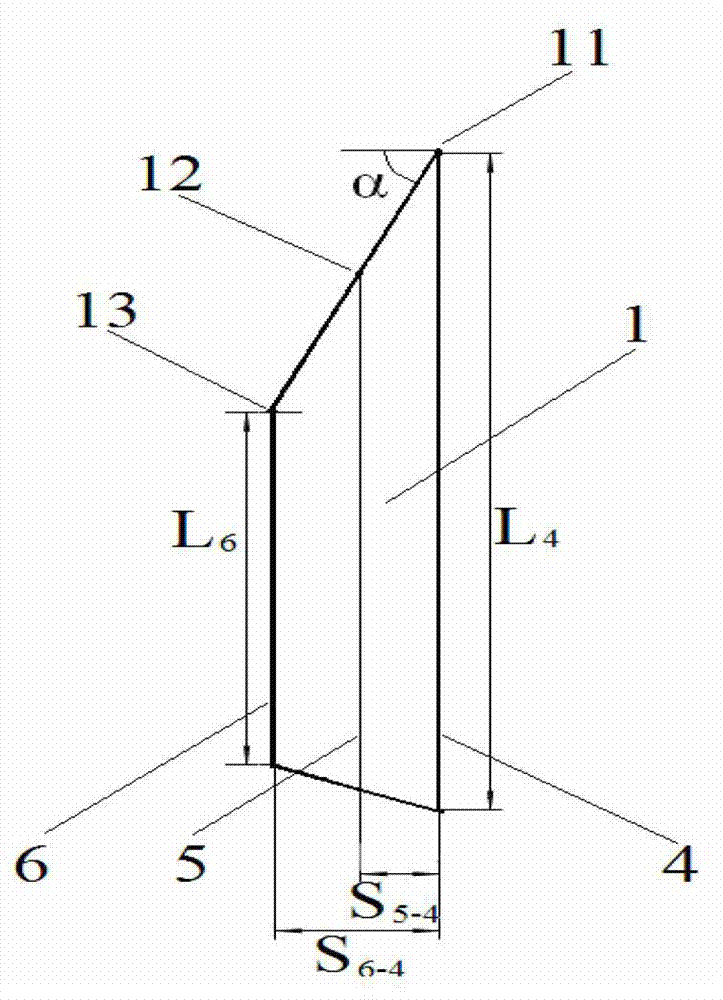

[0072] In this embodiment, the central body 1 includes a control surface 4 at the root of the central body, a control surface 5 at the middle of the central body, and a control surface 6 at the tip of the central body, and the control surface 4 at the root of the central body, the control surface 5 at the middle of the central body and The control surface 6 at the tip of the central body obtains the three-dimensional configuration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com