Beer bottle cap and processing method thereof

A processing method and technology of bottle caps, which are applied in the directions of bottle/container cap, capping, bottle filling, etc., can solve the problems of difficult processing, high force to pull up the bottle cap, pouring out and putting it in a cup to drink, etc. Convenience, many ways to open, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

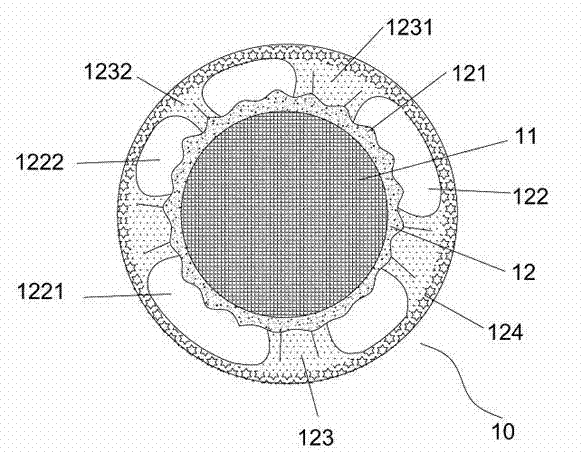

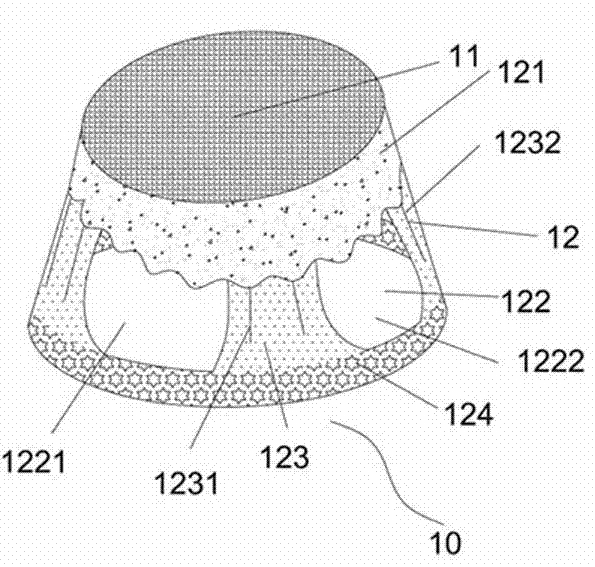

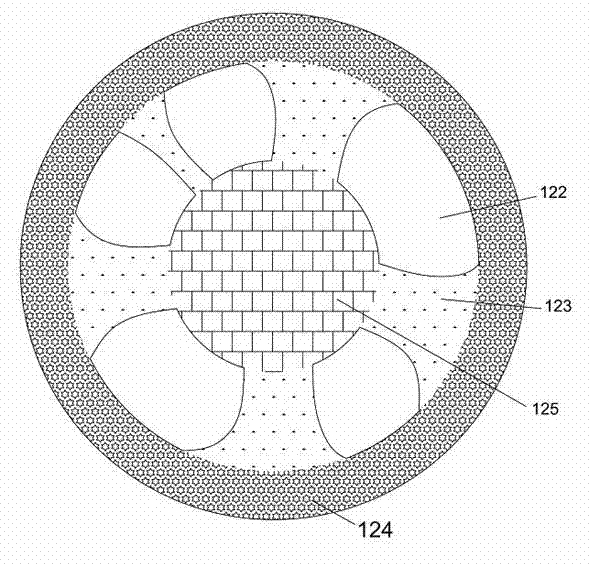

[0036] like Figure 1-2 Shown, a kind of beer bottle cap, this beer bottle cap comprises iron cover shell 10 and is arranged on the sealing rubber gasket (not shown) on the inner top of the iron cover shell, and described iron cover shell 10 comprises a disc-shaped cover portion 11 and a skirt 12 with pleats 121, the pleats 121 are located at the upper end of the skirt, the lower end of the pleats is also provided with a plurality of "U"-shaped perforations 122, and a plurality of "U"-shaped perforations 122 are vertically around the skirt. Arranged, the iron sheet between the two U-shaped perforations is a spoke 123, the upper end of the spoke 123 is connected with the fold 121, and the lower end of the spoke 123 is connected with an annular iron ring 124, and the annular iron ring 124 is located at the bottom of the skirt 12.

[0037] The folds 121 of the skirt, the spokes 123 and the annular iron ring 124 are processed from the same piece of iron sheet, that is, the folds 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com