Large package control equipment for coiling organic membrane and method

A technology for controlling equipment and organic film, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, etc. Influence, increase the volume of the package, and the effect of increasing the volume of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

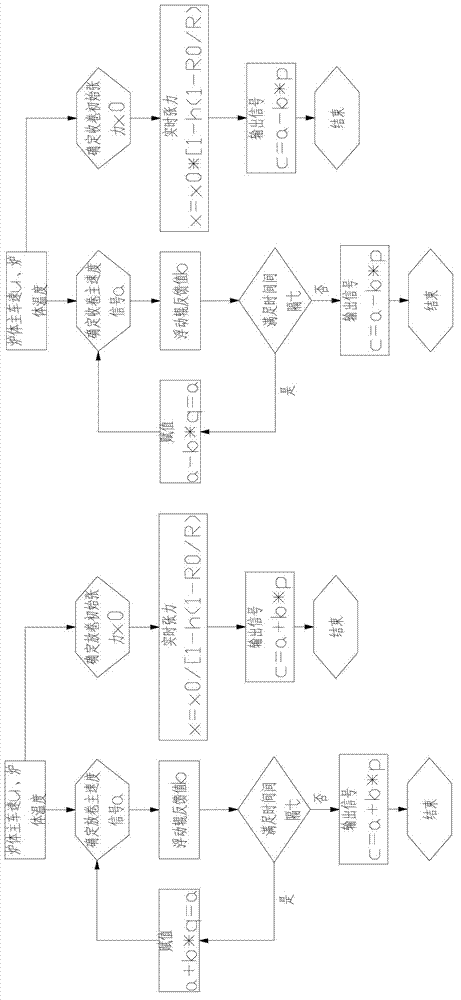

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

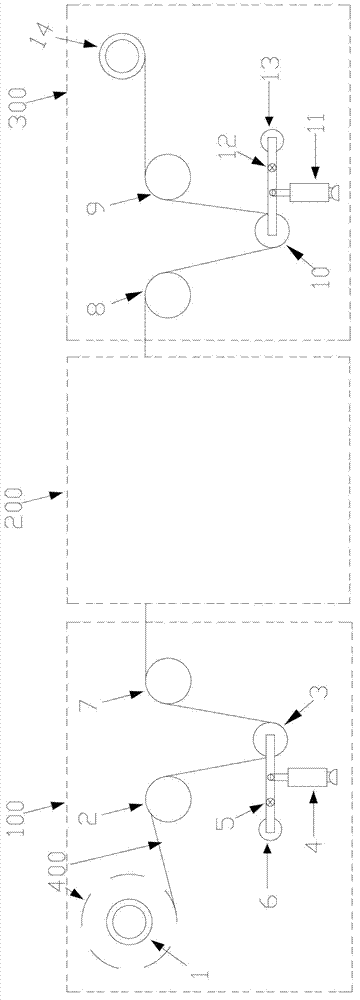

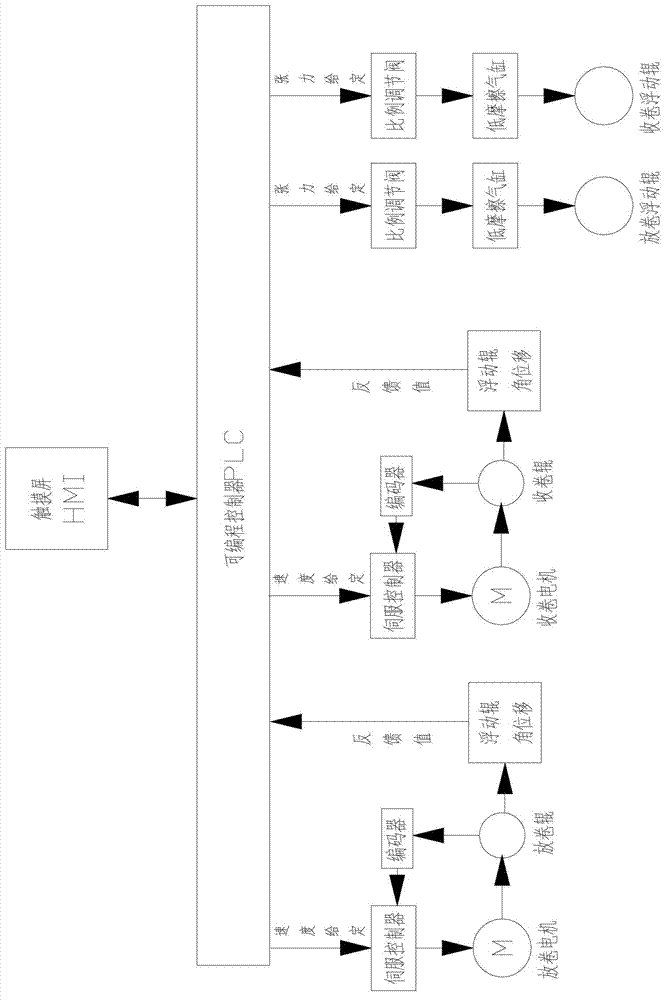

[0018] see figure 1 , the large volume organic film winding equipment includes an unwinding device 100, a furnace body 200, a winding device 300, a programmable logic controller PLC, a touch screen HMI, a servo controller, and the like.

[0019] The unwinding device 100 includes an unwinding servo motor, an unwinding roller 1 connected to the unwinding servo motor, a driven roller 2, a driven roller 7, and a device for detecting and controlling the unwinding tension of the organic film including the tension floating roller 3. Unwinding tension device, the output of the unwinding tension device is connected to the programmable controller PLC.

[0020] The winding device 300 includes a winding servo motor, a winding roller 14 connected to the winding servo motor, a driven roller 8, a driven roller 9, and a device for dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com