Oil resistant sole material and manufacturing method thereof

A shoe sole material and manufacturing method technology, applied in the field of oil-resistant shoe sole materials and its manufacturing, can solve problems such as degumming of shoe soles, deformation, and molecular structure destruction, and achieve excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

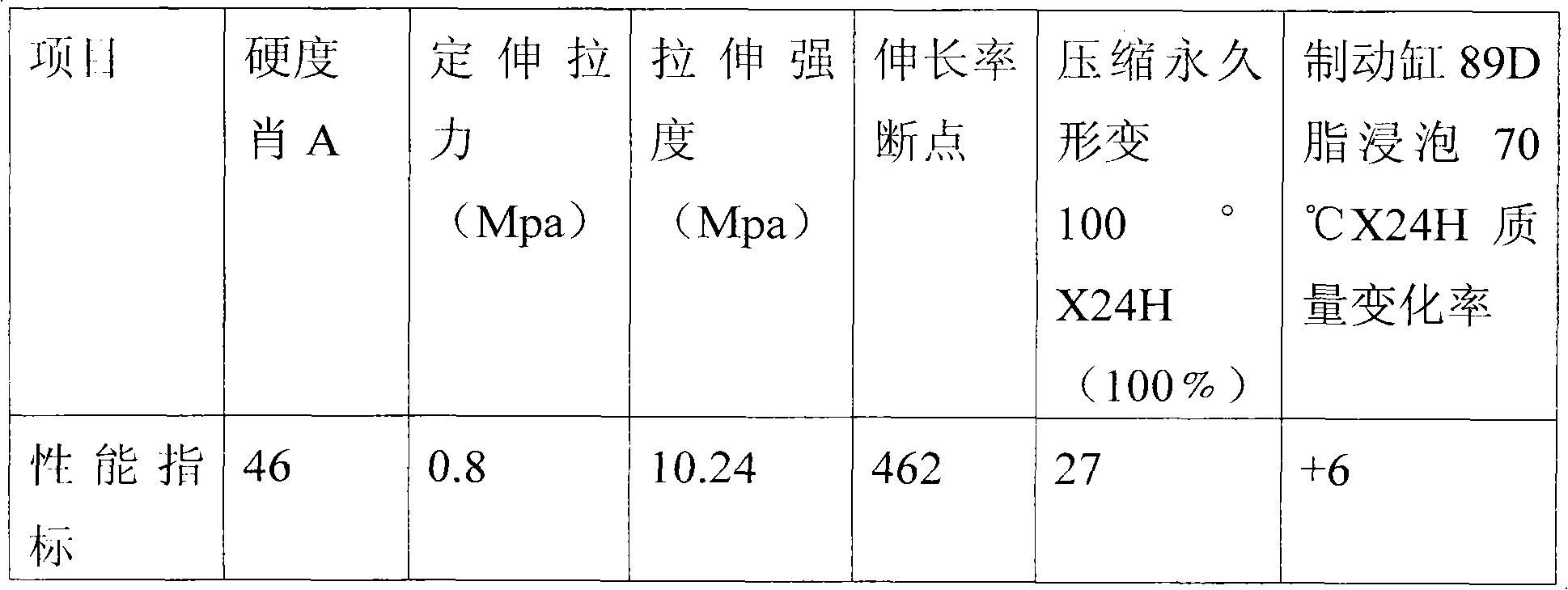

[0021] A material for oil-resistant soles, comprising the following raw materials in weight percent:

[0022] NBR1965: 46.8%;

[0023] Spray carbon black: 28.1%;

[0024] Plasticizer DOS: 9.4%;

[0025] Plasticizer TP-95: 9.4%;

[0026] Antiaging agent RD: 0.7%;

[0027] Stearic acid: 1.4%;

[0028] Active nano zinc oxide: 2.3%;

[0029] Dicumyl peroxide (DCP): 0.84%;

[0030] Trimethylolpropane methacrylate (Crosslinker TM): 1.17%.

[0031] Among them, NBR1965 is provided by China Nandi Chemical; spray carbon black is provided by Tianjin Dolphin Carbon Black; plasticizer DOS is provided by Tianjin Dahe Chemical; plasticizer TP-95 is provided by Shanghai Jinghui Chemical; antioxidant RD is commercially available; stearic acid is provided by Quanzhou Star Chemical Industry; active nano-zinc oxide is commercially available; dicumyl peroxide (DCP) is provided by Shanghai Gaoqiao Petrochemical; trimethylolpropane methacrylic acid Grease (assistant cross-linking agent TM) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com