Longitudinally arranged coal gas integrated powder coal hand fired furnace and pressure loaded steam boiler used for assembling hand fired furnace

A steam boiler, vertical type technology, applied in the field of small and medium-sized loose coal hand burning furnaces, can solve the problems of poor coal adaptability, picky coal use, poor stoker environment, etc., to achieve low energy consumption, safe operation, stable smoke elimination and clean combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

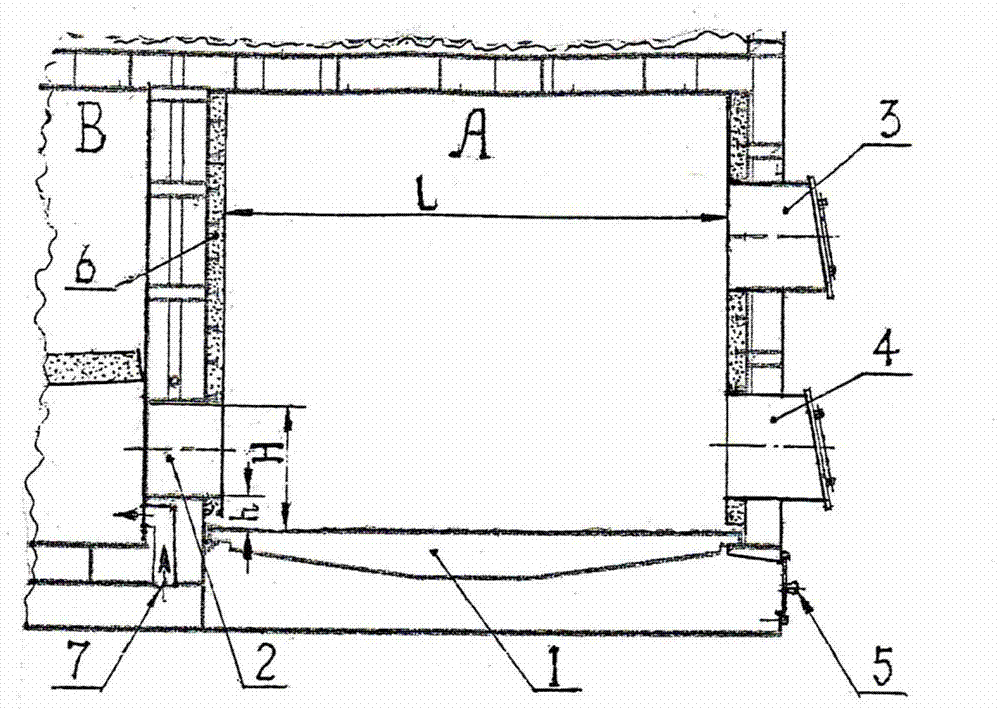

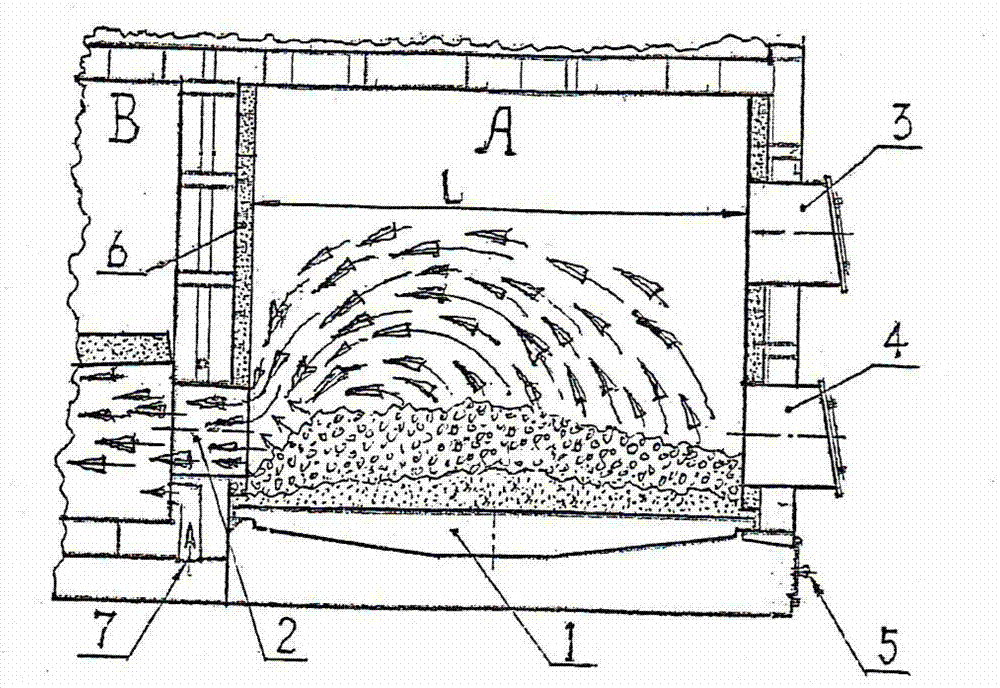

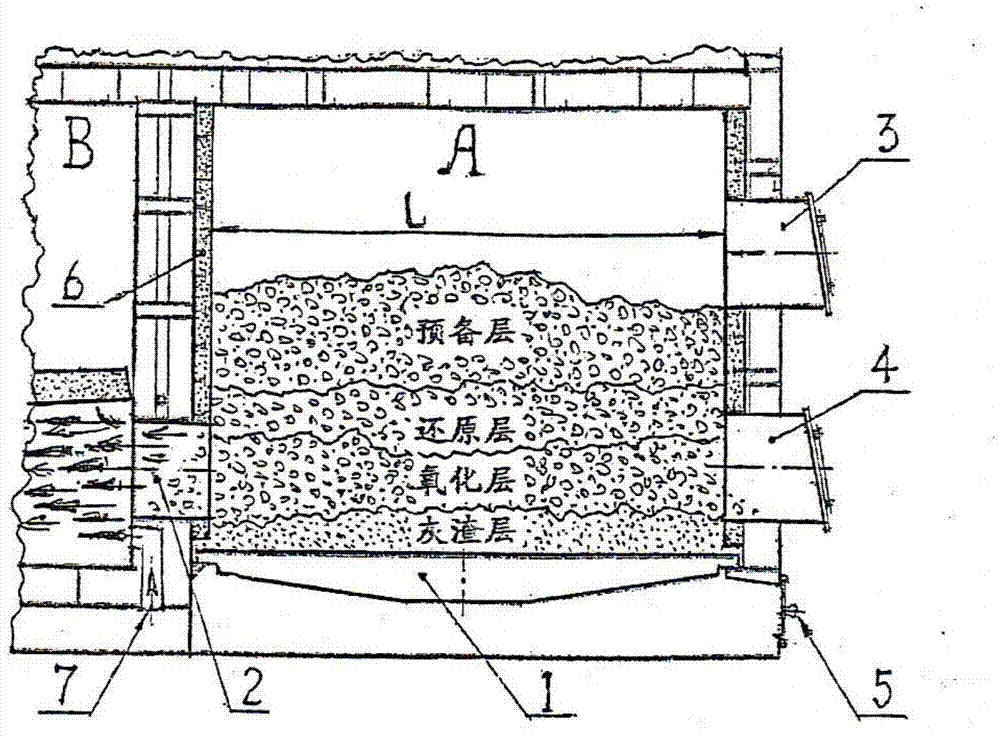

[0022] In the vertical-mounted gas-integrated scattered coal hand-fired furnace provided by the application of the present invention, the space above the single-layer grate 1 of the furnace body is a primary combustion gasification chamber A, also known as a coal-to-gas combustion chamber. The coal port 3, the lower coal port 4 and the primary air damper 5 under the single-layer fire grate 1, and the inner furnace wall opposite to the front furnace wall is provided on the single-layer fire grate 1 which is connected to the secondary combustion chamber The low crater 2, some air outlet pipes 7 nozzle directions of the secondary air duct are parallel with the low crater 2. The flow cross-sectional area of the low crater 2 is 0.37-0.41m 2 / 0.7MW, which is based on the rated power value of 0.7MW per ton of hot water boiler. 21-33% of the longitudinal effective length L of the grate 1, and the maximum does not exceed 372mm. The effective width of the single-layer grate 1 is 0.89...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com