Preparation method of fermented tobacco Dendranthema indicum essential oil

A Shennong incense chrysanthemum, fermentation type technology, applied in essential oils/spices, tobacco, applications, etc., can solve the problems of low efficiency and low oil rate, and achieve the effect of simple process, delicate smoke, and improved aroma texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

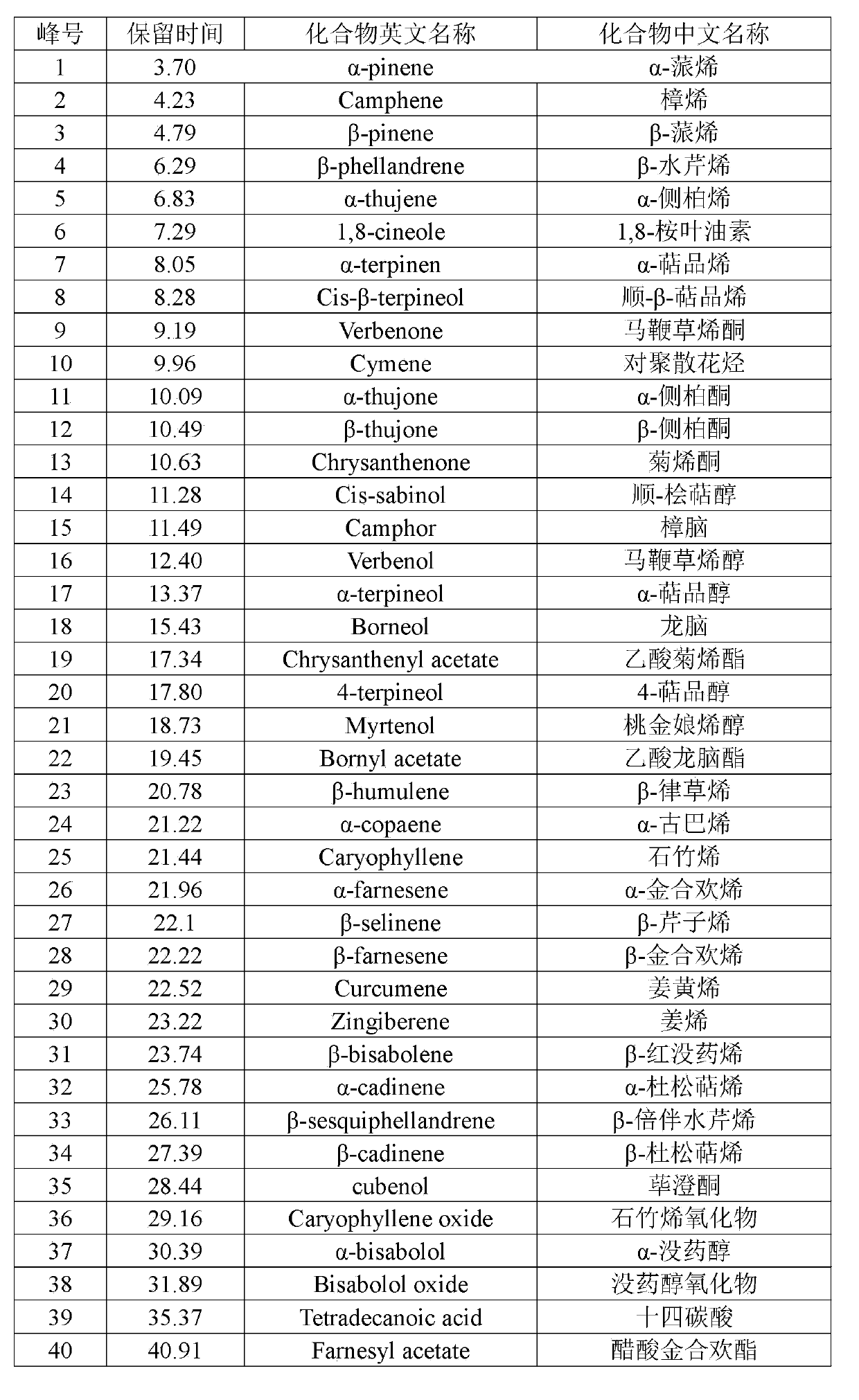

Image

Examples

Embodiment 1

[0022] Weigh Shennong Xiangju and crush Shennong Xiangju into 80 mesh Shennong Xiangju coarse powder, put Shennong Xiangju coarse powder: glucose: water in a ratio of 5:5:90 in a fermenter, at pH 2.5, stirring speed is Under the condition of 250r / min and ventilation volume of 1VVM, first ferment at 15°C for 7 days, then ferment at 5°C for 28 days until the fermentation liquid is obtained; then the fermentation liquid is put into a bottle, extracted with a volatile oil extractor, and put in an oil-water separator Separating and collecting the obtained oil layer is the fermented Shennong Xiangchrysanthemum essential oil for tobacco.

Embodiment 2

[0024] Weigh Shennong Xiangju and crush Shennong Xiangju into 100 mesh Shennong Xiangju coarse powder, put Shennong Xiangju coarse powder: glucose: water in a ratio of 8: 2.5: 89.5 in a fermenter, at pH 3, the stirring speed is Under the condition of 200r / min and ventilation volume of 2VVM, first ferment at 20°C for 5 days, then ferment at 8°C for 25 days until the fermentation liquid is obtained; then the fermentation liquid is put into a bottle, extracted with a volatile oil extractor, and put in an oil-water separator Separating and collecting the obtained oil layer is the fermented Shennong Xiangchrysanthemum essential oil for tobacco.

Embodiment 3

[0026] Weigh Shennong Xiangju and crush Shennong Xiangju into 120 mesh Shennong Xiangju coarse powder, put Shennong Xiangju coarse powder: glucose: water in a ratio of 10:5:80 in a fermenter, at pH 4, stirring speed is Under the conditions of 180r / min and ventilation volume of 3VVM, first ferment at 20°C for 7 days, then ferment at 10°C for 22 days until the fermentation liquid is obtained; then the fermentation liquid is put into a bottle, extracted with a volatile oil extractor, and put in an oil-water separator Separating and collecting the obtained oil layer is the fermented Shennong Xiangchrysanthemum essential oil for tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com