Dual-gas-supply inflation system applied to vacuum coating equipment and inflation method of system

A technology of vacuum coating and gas filling system, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of poor environmental adaptability of coating equipment, prolong the vacuuming time, affect the high vacuum degree, etc. problems, to achieve the effect of improving environmental adaptability, speeding up the rate of vacuuming, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. The examples described below are only for illustrating the present invention, and are not intended to limit the present invention.

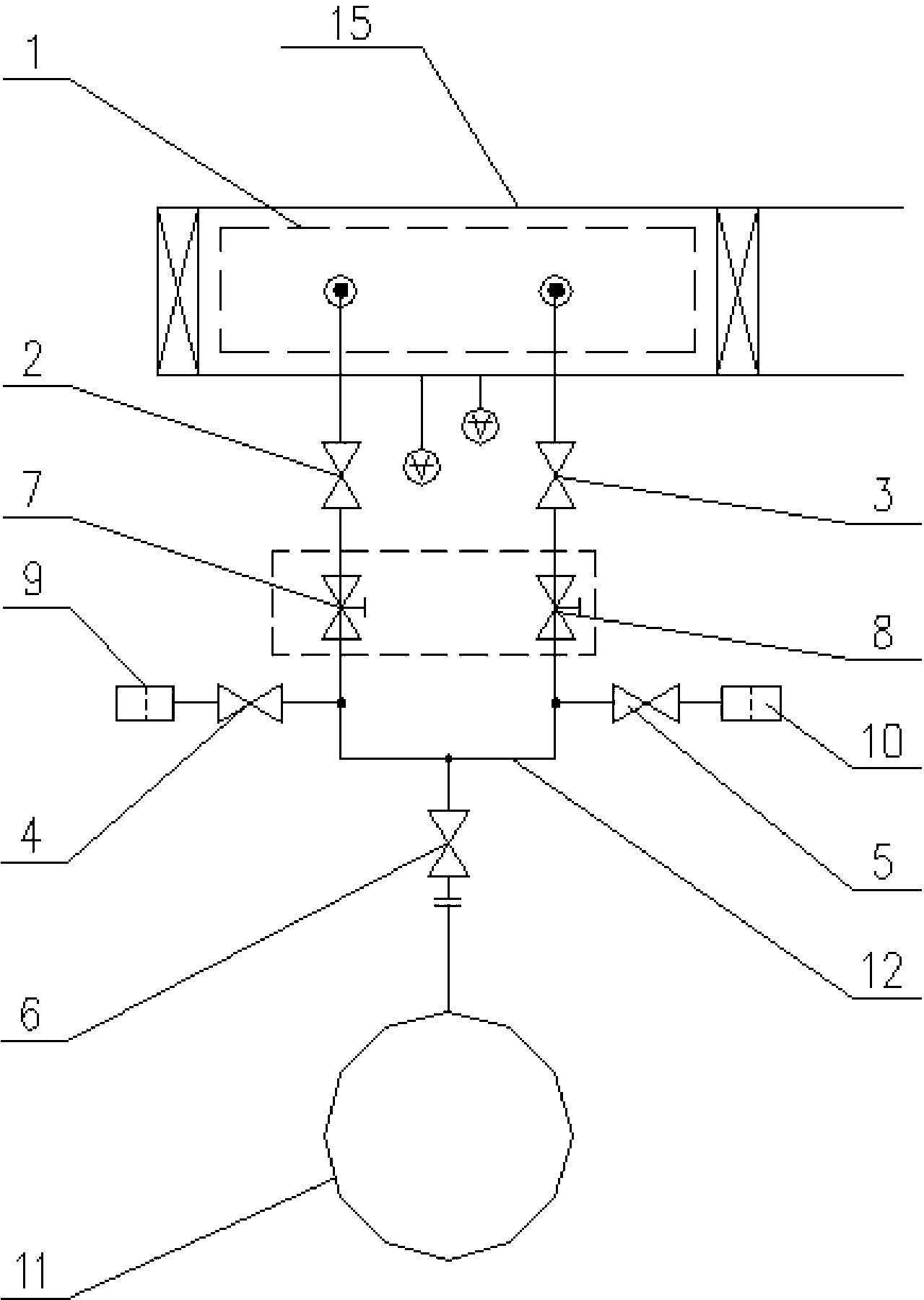

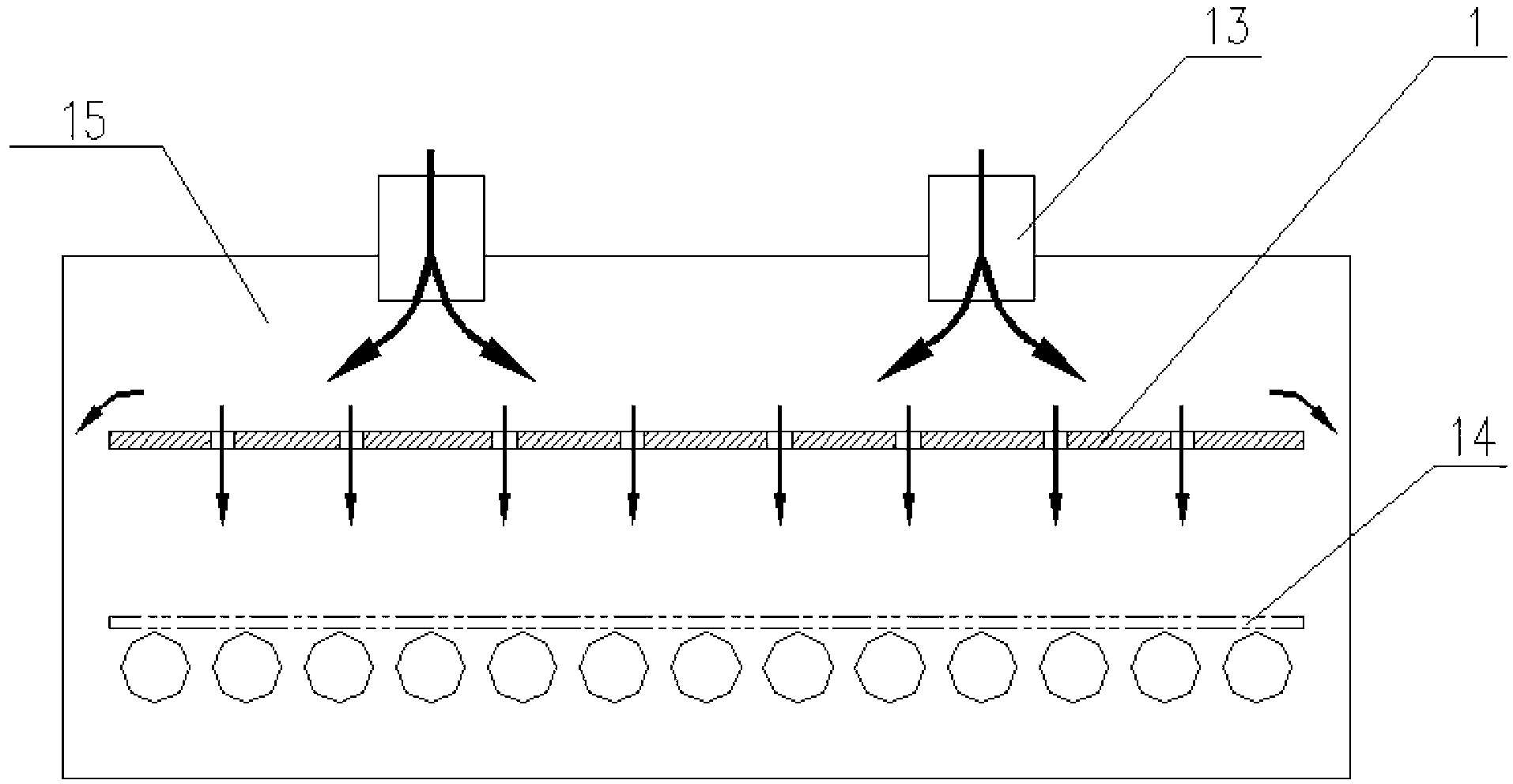

[0015] Such as figure 1 As shown, the present invention is a dual gas source inflation system for vacuum coating equipment, including an inlet / outlet chamber, a vacuum detection element is installed on the side wall of the inlet / outlet chamber, and it consists of five pneumatic butterfly valves BV1, BV2, BV3, BV4 , BV5, filter muffler 9, filter muffler 10, a dry compressed gas tank 11 and a gas buffer plate 1 composition. The components are connected by stainless steel pipes 12 . Pneumatic butterfly valve BV1 and pneumatic butterfly valve BV2 are connected in parallel and then connected in series with pneumatic butterfly valve BV5 and dry compressed air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com