Production technology of all-wood-pulp unbleached ecological environmentally-friendly toilet paper

A production process and toilet paper technology, applied in the field of papermaking technology, can solve the problems of human health hazards and carcinogenicity, and achieve the effect of convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

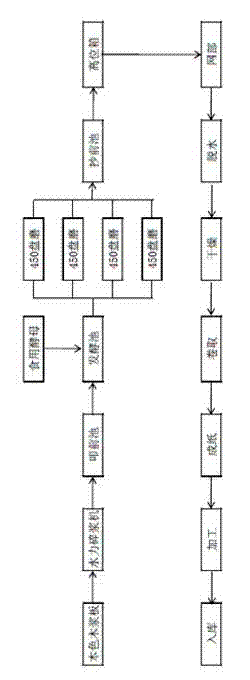

[0013] refer to figure 1 , a kind of whole wood pulp natural color ecological environmental protection toilet paper production process, comprises the following steps:

[0014] (1) Use uncolored wood pulp boards with a mass fraction of 100% to decompose with a hydraulic pulper at a temperature of 40°C-50°C for 1.5 hours, control the mass concentration of the pulp to 4-5%, and then pump it to the pre-knock pool;

[0015] (2) Add edible yeast accounting for 0.1% of the weight of the natural color wood pulp board to the knocking pool, and ferment for 4-6 hours at 28-30°C;

[0016] (3) The fermented pulp is beaten by 4 sets of 450 disc mills, and then pumped to the forecourt;

[0017] The specific beating process is as follows:

[0018] Beating concentration: 3.8-4.0%

[0019] Percussion degree 42-45°SR

[0020] Wet weight 4-5g.

[0021] (4) The finished beating pulp is pumped to the high-level box, sent to the wire section for forming, and the concentration of the net is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com