Raising speed control energy saving system and method for excavator

An energy-saving system and excavator technology, which is applied in mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc., can solve problems such as fuel consumption, deterioration of work performance, and heating of hydraulic systems, to avoid The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

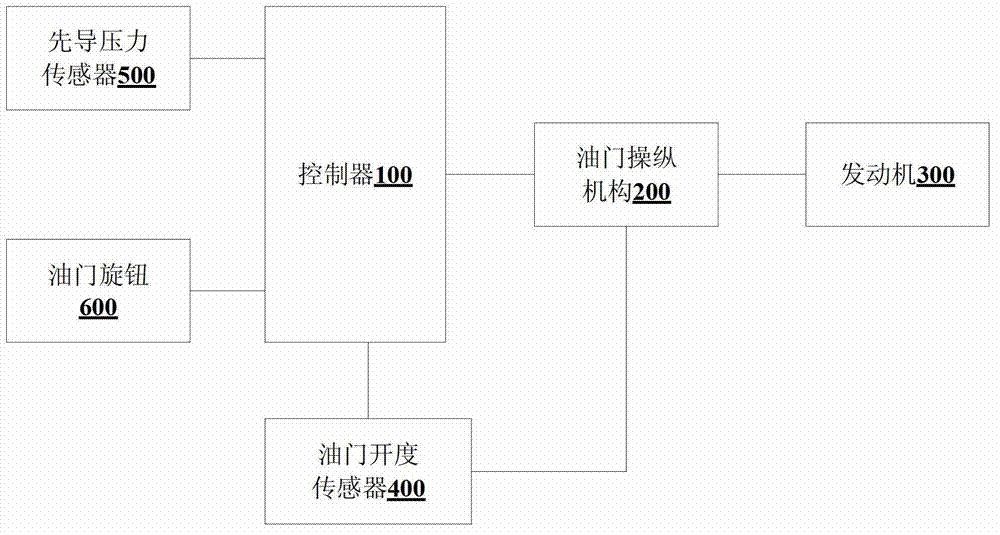

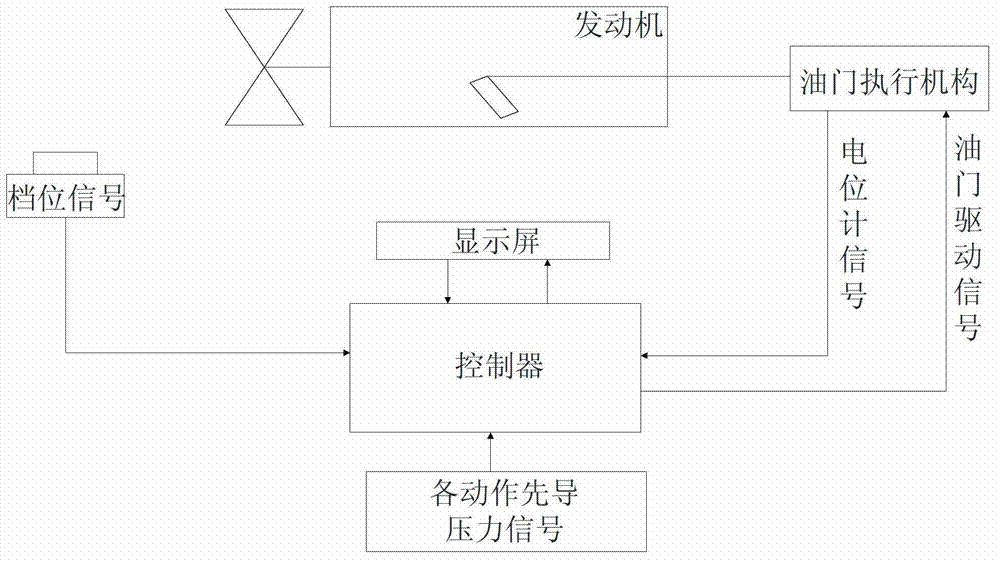

[0026] refer to figure 1 and figure 2 .

[0027] The speed-up control and energy-saving system of the excavator in this embodiment includes: a pilot pressure sensor 500 , a controller 100 and an accelerator control mechanism 200 .

[0028] Among them, the pilot pressure sensor 500 is used to detect the pilot pressure signal of each action of the excavator; the controller 100 is connected with the throttle knob 600 of the excavator and the pilot pressure sensor 500; In the case of no-load speed control signal; and, after obtaining the working gear, if the pilot pressure signal is further detected, the target speed control signal is sent; the throttle control mechanism 200 is connected with the controller 100 for The load speed control signal or the target speed control signal controls the opening and closing degree of the accelerator, so as to control the speed of the engine 300 to be between the no-load speed and the target speed.

[0029] Wherein, the no-load rotational s...

no. 2 example

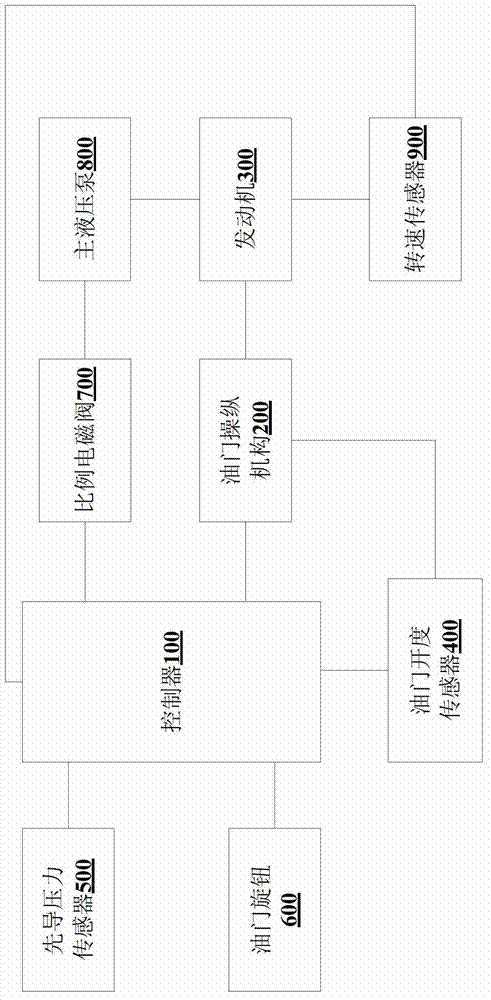

[0036] refer to image 3 and Figure 4 .

[0037]The speed-up control and energy-saving system of the excavator in this embodiment includes: a pilot pressure sensor 500 , a controller 100 , an accelerator operating mechanism 200 , an accelerator opening sensor 400 , a proportional solenoid valve 700 and a speed sensor 900 .

[0038] Among them, the pilot pressure sensor 500 is used to detect the pilot pressure signal of each action of the excavator; the controller 100 is connected with the throttle knob 600 of the excavator and the pilot pressure sensor 500; In the case of no-load speed control signal; and, after obtaining the working gear, if the pilot pressure signal is further detected, the target speed control signal is sent; the throttle control mechanism 200 is connected with the controller 100 for The load speed control signal or the target speed control signal controls the opening and closing degree of the accelerator, so as to control the speed of the engine 300 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com