Exhaust system for passenger car clutch

An exhaust system and clutch technology, which is applied in the exhaust system field of passenger car clutches, can solve the problems of heavy air bubble removal, poor clutch operation, oil leakage of clutch oil pipes, etc., and achieves wide application range, reduced work intensity, and tight seal good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

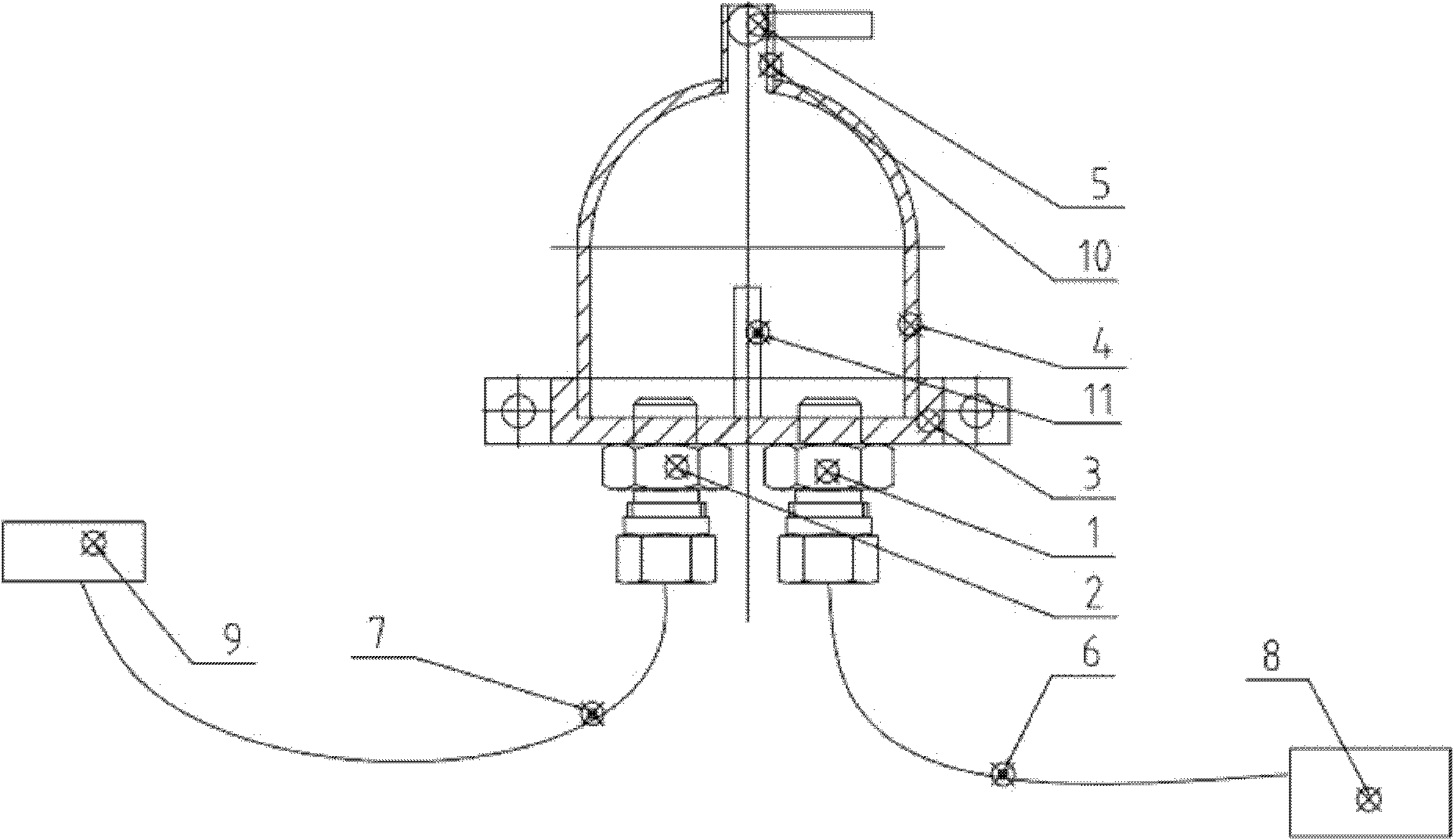

[0016] Such as figure 1 As shown, an exhaust system for passenger car clutches, including exhaust valve oil outlet joint 1, exhaust valve oil inlet joint 2, exhaust valve base 3, transparent cover 4, deflation ball valve 5, clutch oil outlet pipe 6. Clutch oil inlet pipe 7, clutch sub-pump 8, clutch master cylinder 9, air release ball valve base 10, the exhaust valve oil outlet joint 1 is connected with the clutch sub-pump 8 through the clutch oil outlet pipe 6, the exhaust valve The oil inlet joint 2 of the air valve is connected with the clutch master cylinder 9 through the oil inlet pipe 7 of the clutch. The base 3 of the exhaust valve is connected with the transparent cover 4 to form an accommodating space. The gas valve oil inlet joint 2 respectively passes through the exhaust valve base 3 and communicates with the accommodation space. The deflated ball valve base 3 is fixed on the upper end of the transparent cover 4, and the described deflated ball valve 5 is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com