Novel top oxygen blast metal hose for steel converter

A technology for steelmaking converters and metal hoses, applied in the direction of hoses, pipes, pipeline protection, etc., can solve the problems of not meeting the requirements of modern use, not meeting the steelmaking process of converters, affecting the activities of oxygen lance trolleys, etc., to achieve security The effects of life, property and safety, light weight and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

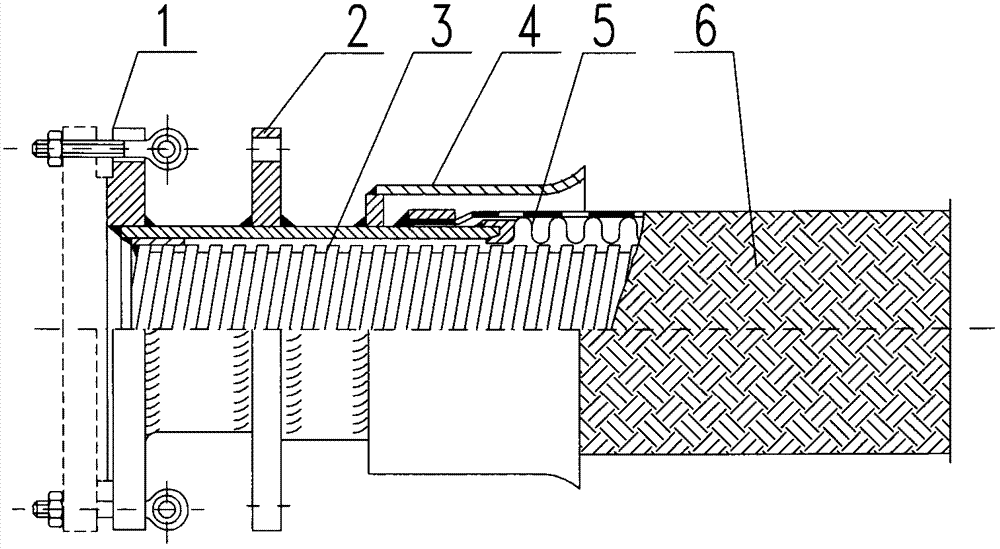

[0010] refer to figure 1 , the specific embodiment adopts the following technical solutions: it includes connecting flange 1, hoisting flange 2, stainless steel wear-resistant lining 3, extended protective sleeve 4, main body bellows 5 and outer protective net 6, the main body bellows 5 The end is connected to the end of the pipe joint, and the joint is provided with an extended rigid protective sleeve, and the inner wall of the main corrugated pipe 5 and the pipe joint is provided with a stainless steel wear-resistant lining 3, and the outer wall of the main corrugated pipe 5 is tightly provided with an outer layer The protective net 6 and the outer wall of the pipe joint are respectively welded with a connecting flange 1 and a lifting flange 2 .

[0011] The bellows 5 of the main body adopts an overall ring wave, with few joints, which increases the number of fatigue bending and greatly improves the service life of the product. The service life of the product can reach more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com