Ejecting air flue of instant freezer

A quick-freezing machine and air duct technology, applied in lighting and heating equipment, cooling fluid circulation devices, household appliances, etc., can solve the problems of uneven freezing and slow efficiency, and achieve the effect of uniform freezing and high freezing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

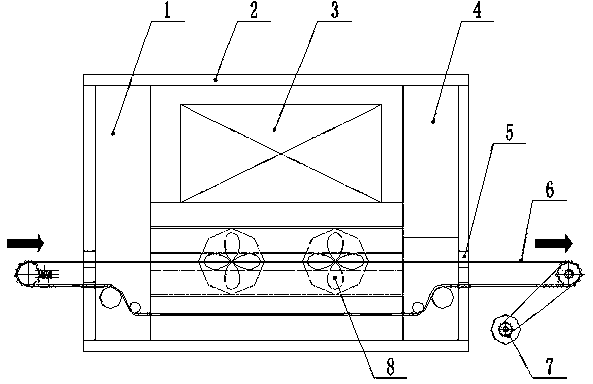

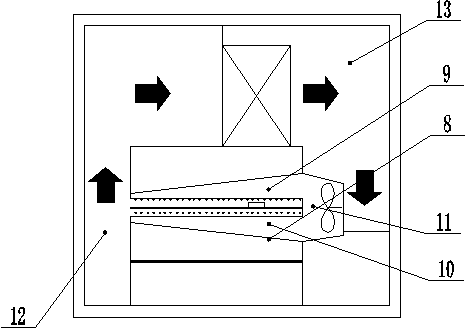

[0018] like figure 1 and figure 2 As shown, the spray air duct of the quick-freezing machine in this embodiment includes a heat preservation body 2 and a conveyor belt 6, a heat exchanger 3 and a heat exchange fan 8 are arranged in the heat preservation body 2, and the input end of the heat exchanger 3 is connected to the return air duct 12 , The output end of the heat exchanger 3 is provided with an air supply channel 13, the air supply channel 13 is connected to the air distribution cavity 11, and the upper air injector 9 and the lower air injector 10 at the port of the air distribution cavity 11 are wedge-shaped. The heat exchange fan 8 is arranged in the air distribution cavity 11 .

[0019] Both ends of the thermal insulation body 2 are respectively provided with an inlet cold and heat balance room 1 or / and an outlet cold and heat balance room 4 . Due to the large temperature difference between the inside and outside of the heat preservation body, the moment when the f...

Embodiment 2

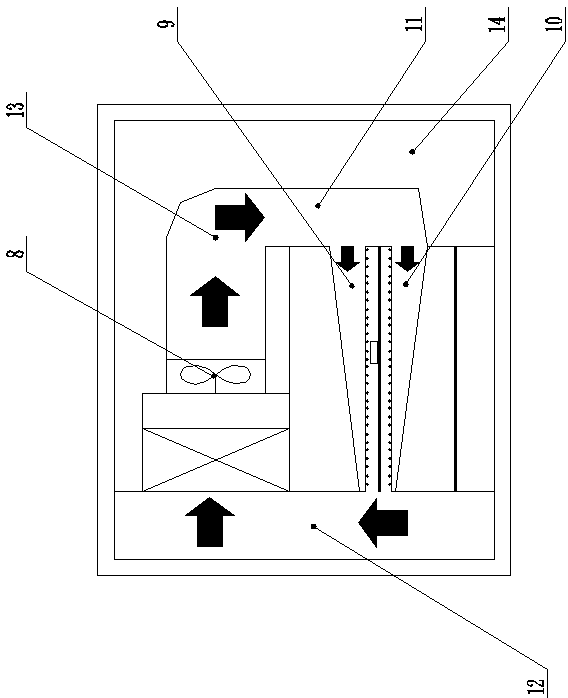

[0024] like image 3 and Figure 4 As mentioned above, the heat exchange fan 8 in this embodiment is arranged at the outlet of the heat exchanger 3 , and the maintenance channel 14 is provided in the heat preservation body 2 . Other structure and usage mode are the same as embodiment 1.

[0025] The inspection channel 14 is reserved, which can facilitate the staff to carry out inspection and maintenance work.

[0026] Compared with Embodiment 1, in this embodiment, the heat exchange fan 8 is arranged at the outlet of the heat exchanger, which can improve the cold air utilization efficiency.

Embodiment 3

[0028] like Figure 5 As shown, the heat exchange fan 8 in this embodiment is arranged at the outlet of the heat exchanger 3, and the heat preservation body 2 is provided with a deflector 15, and other structures and usage methods are the same as in the first embodiment.

[0029] In this embodiment, deflectors 15 are provided to allow cold air to enter the air distribution chamber smoothly, and the heat exchange fan 8 is arranged at the outlet of the heat exchanger, which can not only improve the utilization rate of cold air, but also reduce Production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com