A multi-parameter automatic measurement system for rolling bearing outer ring based on comparative measurement method

A technology of comparative measurement and bearing outer ring, which is applied in the field of measurement and testing, can solve problems such as high labor intensity and human error, achieve the effect of improving measurement accuracy and realizing high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention will be further illustrated by the following examples.

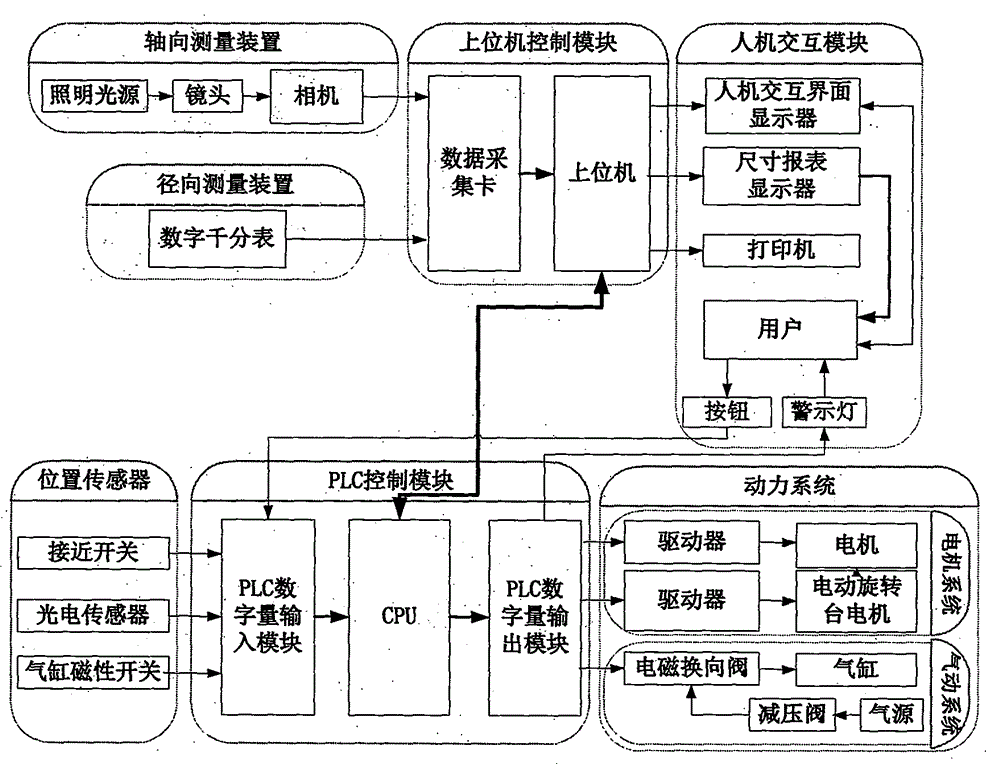

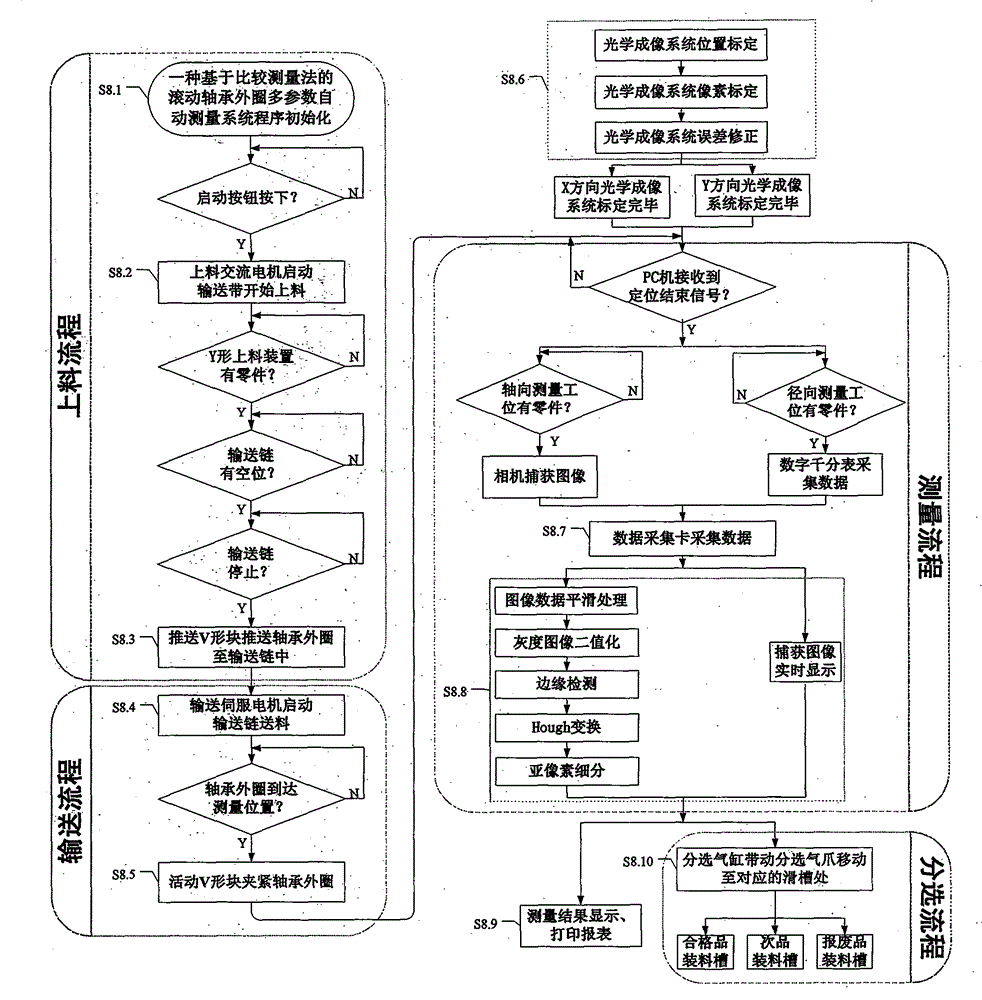

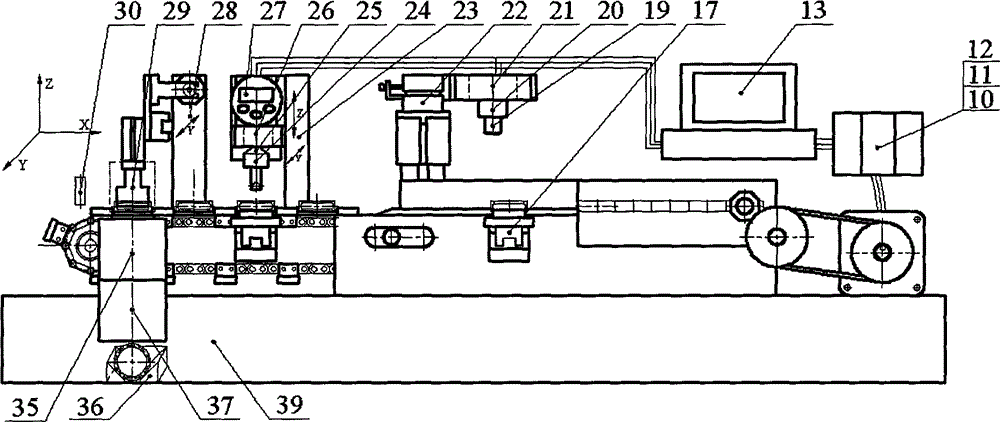

[0040] The front view and top view of a rolling bearing outer ring multi-parameter automatic measurement system based on the comparative measurement method of the present invention are as follows figure 1 and figure 2 As shown, the system includes a feeding mechanism, a chain conveying mechanism, an axial parameter measuring device, a radial parameter measuring device, a sorting mechanism, a PLC control module, a host computer control module and a human-computer interaction module. The middle part of (39) is equipped with a chain conveying mechanism that conveys the bearing outer ring (8) to the axial and radial measuring stations, and is used to push the bearing outer ring one by one to the feeding mechanism at the entrance of the chain conveying mechanism Located on one side of the entrance of the chain conveyor mechanism, the sorting mechanism for sorting the outer rings of the bearings into qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com