An Ultrasonic Surface Wave Detection Method for Fatigue Cracks in Locomotive Connecting Rods

An ultrasonic surface wave and ultrasonic technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as poor operability, reduced locomotive running rate, and missed detection, and avoid overall disassembly work, detection rate and The effect of satisfying reliability and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An ultrasonic surface wave detection method for fatigue cracks of locomotive connecting rods according to the present invention,

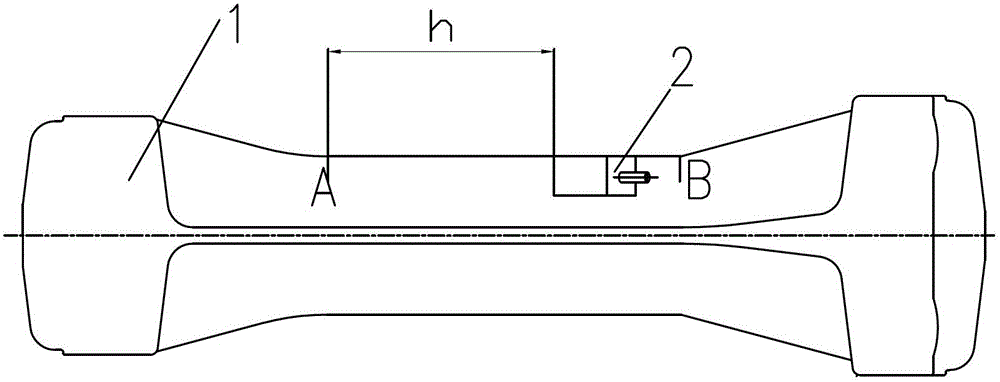

[0014] (1) Place the ultrasonic surface wave probe 2 on the connecting rod physical test block 1, and move the ultrasonic surface wave probe 2 back and forth to test the artificial defects on the connecting rod physical test block 1, and connect it with the ultrasonic surface wave probe 2 The ultrasonic detector receives the reflected echo signal of the surface wave, displays the reflected echo signal on the display screen of the ultrasonic detector, and performs horizontal ranging calibration and the starting point of the reflected echo amplitude for the ultrasonic detector and the ultrasonic surface wave probe Sensitivity Calibration.

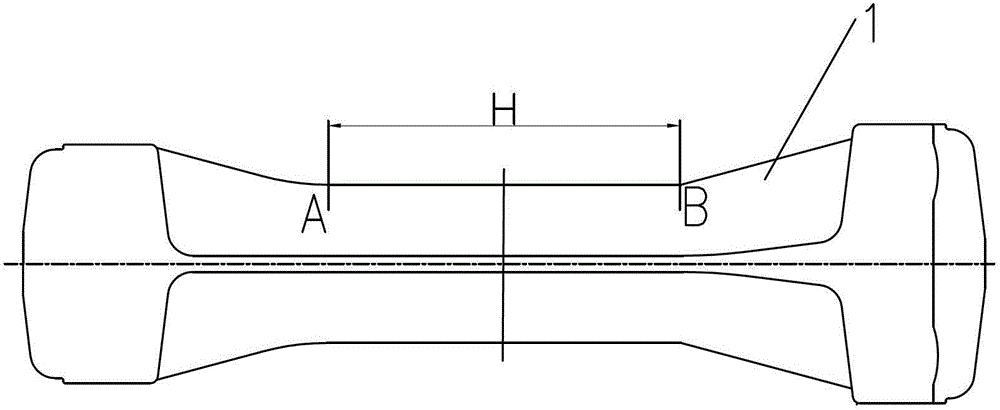

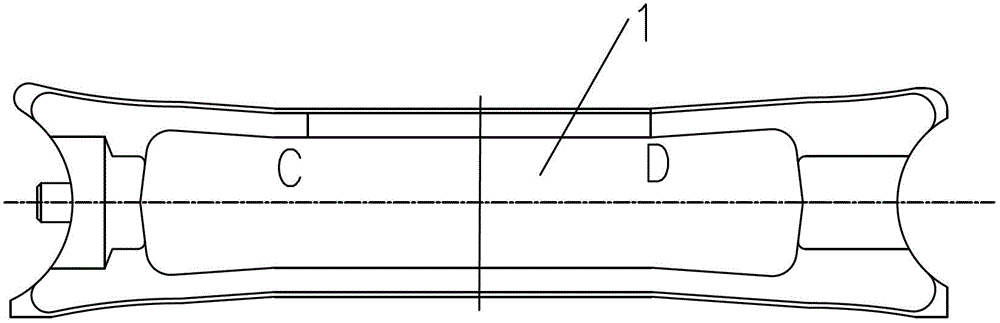

[0015] See figure 1 , 2 As shown, the artificial defect of the connecting rod physical test block 1 of the present invention is a notch. There are at least two notches on each side of the rod reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com