Method and device for measuring propeller rotating speed of underwater direct current brushless thruster

A DC brushless and thruster technology, applied in measuring devices, linear/angular velocity measurement, velocity/acceleration/shock measurement, etc., can solve problems such as failure to achieve electrical isolation, mutual interference, poor system reliability, etc., and achieve strong anti-interference ability, ensuring work reliability, and the effect of small error in speed measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe the present invention below in conjunction with specific embodiment:

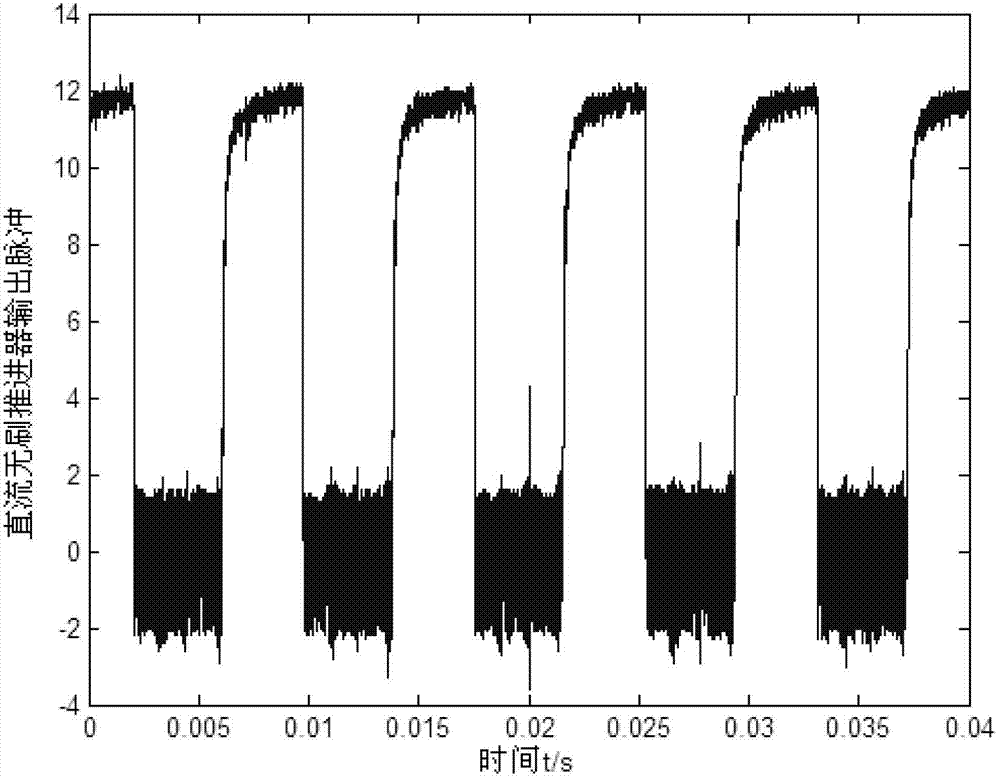

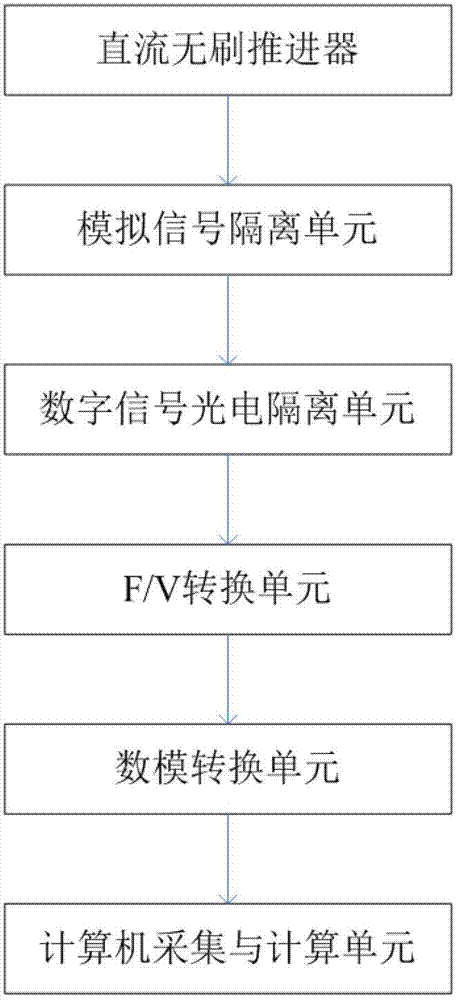

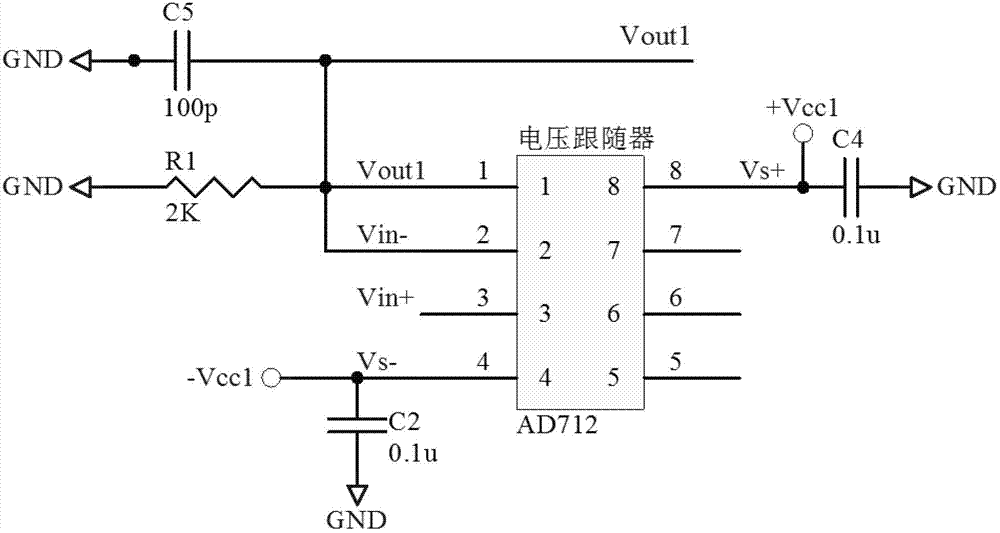

[0034] The underwater DC brushless thruster used in this embodiment is a DC brushless thruster developed and produced by the American TECNADYNE company. The thruster integrates a DC brushless motor, a DC brushless motor controller and a propeller, and has a small size. , light weight, easy to use and other advantages, the maximum pressure depth can reach 1500m. The brushless DC motor controller adopts +12VDC power supply, the command for speed control is -5VDC~+5VDC, and the output is 0~12VDC speed digital pulse signal, which is used for propeller speed measurement. However, since the DC brushless motor and the DC brushless motor controller are sealed in a small space, the output speed digital pulse signal is subject to electromagnetic interference from the DC brushless motor, and there is a large interference. figure 1 The original rotational speed digital pulse signal output by MODEL521 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com