Method for making waveguide by using laser

A laser and waveguide technology, applied in the field of photonic information, can solve the problems of smaller refractive index and inability to form a waveguide to guide light, etc., and achieve the effect of reduced waveguide loss, flexible adjustment, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

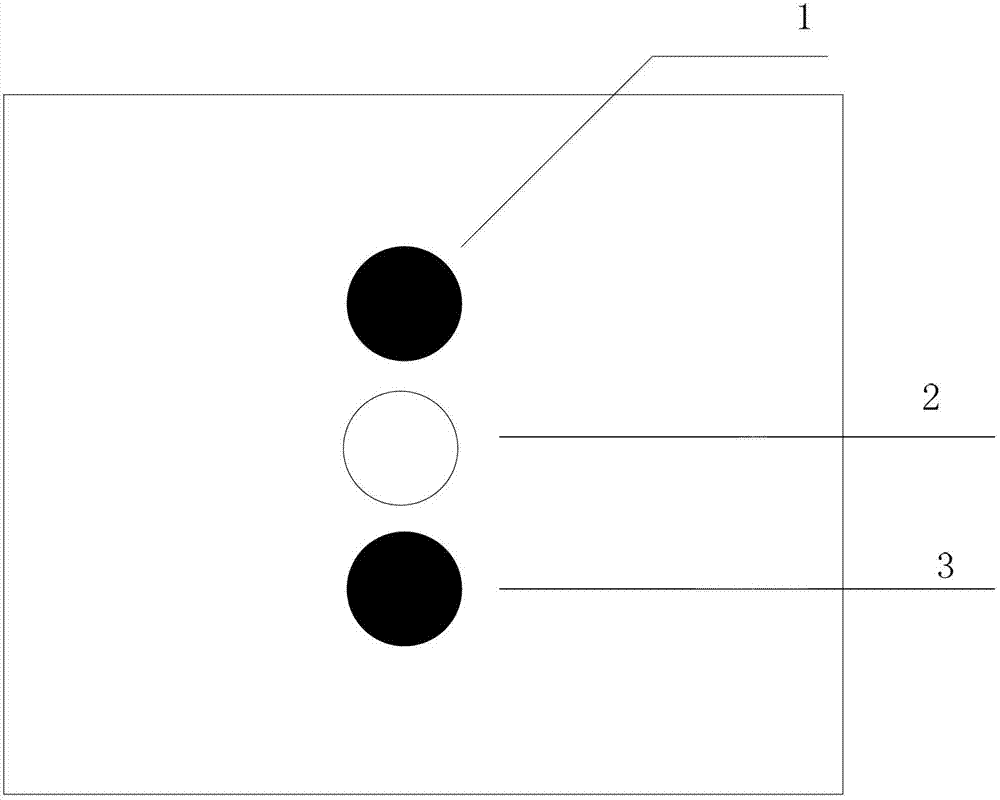

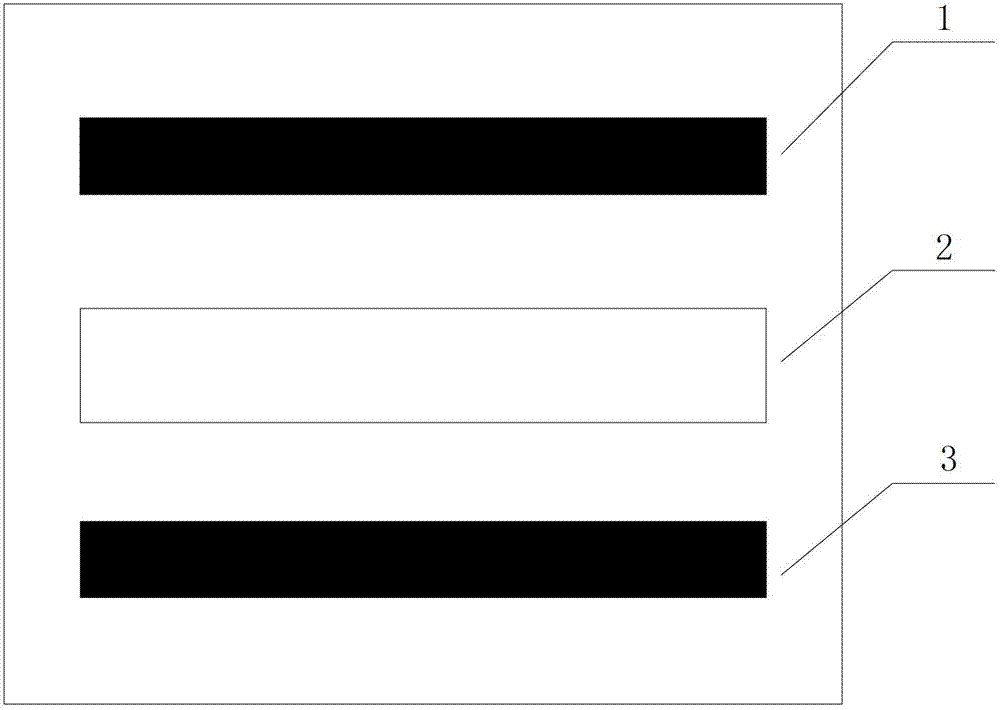

[0029] see figure 1 , figure 2 , the present invention proposes a method for making a waveguide with a laser, comprising the following steps:

[0030] 1) Expand the laser beam emitted by the laser through the collimation system;

[0031] 2) The expanded laser passes through the 1 / 2λ wave plate;

[0032] 3) The emitted laser light in step 2) is focused by a microscope objective lens to form a writing laser light;

[0033] 4) Applying the writing laser to the optical sample for trace scanning to form a waveguide, the specific steps of step 4) are:

[0034] 4.1) Place the optical sample on the three-dimensional control platform;

[0035] 4.2) Move the three-dimensional control platform so that the optical sample on the three-dimensional control platform and the writing laser are perpendicular to each other;

[0036] 4.3) Move the three-dimensional control platform laterally, so that the writing laser scans the first waveguide 1 on the optical sample;

[0037] 4.4) Repeat s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com