Self-supporting tight tube optical fiber bundling optical cable

A tight-buffered optical fiber and self-supporting technology, which is applied in the direction of fiber mechanical structure, can solve the problems of large joint loss, complicated construction, and reduced reliability, so as to reduce construction costs, reduce link optical fiber joint loss, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

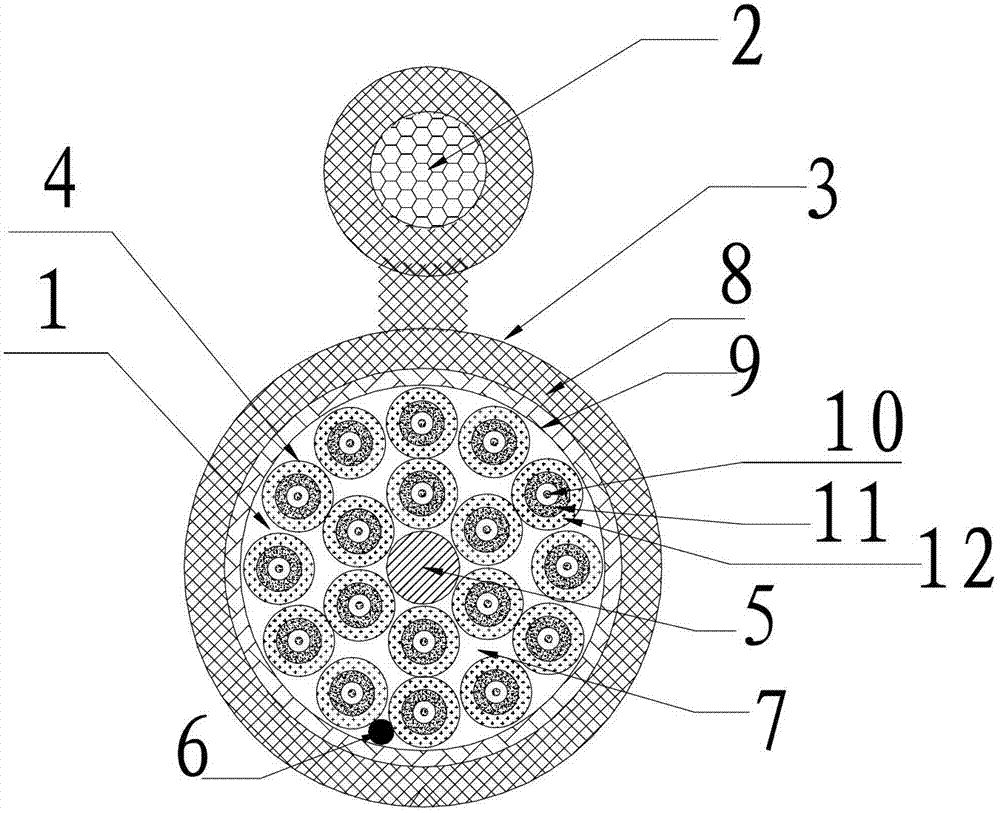

[0010] see figure 1 , the embodiment of the present invention includes:

[0011] A self-supporting tight-buffered optical fiber bundled cable, the self-supported tight-buffered optical fiber bundled cable includes a tight-buffered optical fiber bundled cable core 1, a steel wire suspension wire 2 and a general outer sheath 3, the steel wire suspension wire 2 and the tight-buffered optical fiber bundled cable The core 2 is placed in parallel up and down and then wrapped and sealed by the overall outer sheath 3; the tight-buffered optical fiber bundled cable core 1 includes a plurality of tight-buffered optical fiber single-core indoor optical cables 4 twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com