System and method for controlling water level of deaerator

A technology of water level control and deaerator, applied in the direction of control/regulation system, liquid level control, non-electric variable control, etc., can solve the problems of inability to meet variable load conditions, difficult to meet control requirements, poor controllability, etc., to achieve Effect of shortening water level rise/fall time and stabilization time, good tracking and suppression of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The system and method for controlling the water level of the deaerator according to the present invention will be described in detail below with reference to the accompanying drawings.

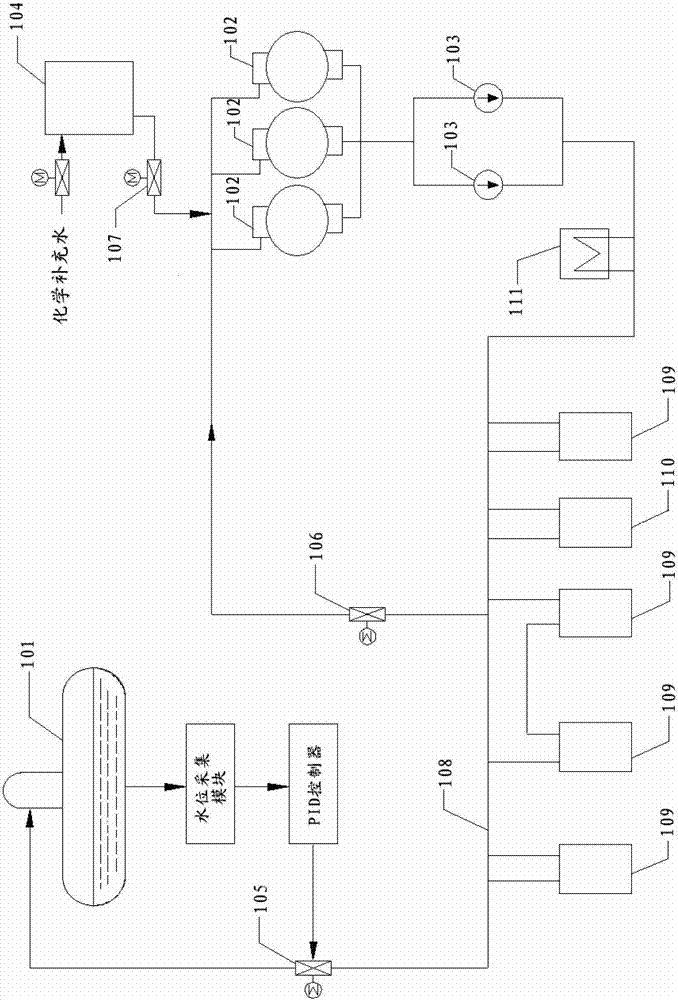

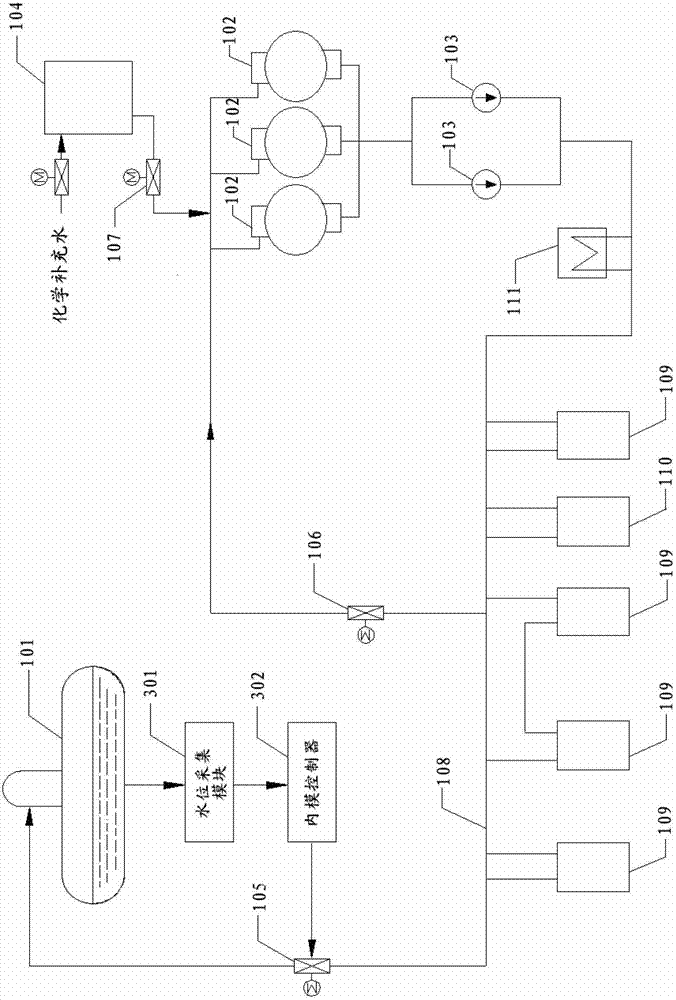

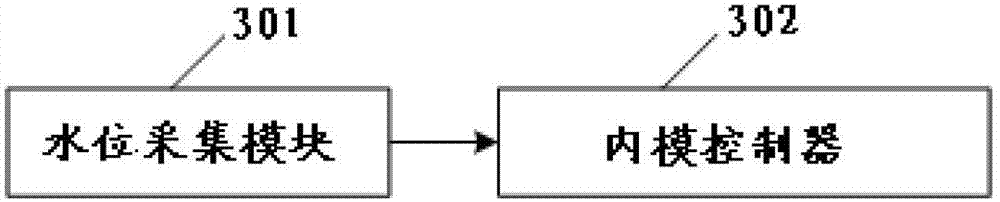

[0020] Such as figure 2 As shown, the condenser 102 generally operates at a low water level, and the condensate pump 103 has a self-regulating function, that is, when the condenser 102 reaches a certain water level, the condensate pump 103 automatically works to change its outlet flow rate to keep the condenser 102 low. water level operation. In order to ensure the safety of the operation of the condensate pump 103 , the outlet pressure of the condensate pump 103 should be kept within a certain range, which is mainly realized by the deaerator regulating valve 105 and the recirculation regulating valve 106 . Considering that the water volume of the condenser 102 is small and the safety performance of the water level of the condenser 102 is high, a pressure regulator can be added at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com