A control system and control method for controlling the reaction temperature of a cracking furnace

A technology of control system and control method, which is applied in general control system, control/regulation system, adaptive control, etc., can solve the problems of increased experiment time, unsatisfactory temperature control effect, strong coupling influence of cracking furnace temperature, etc., to achieve shortening Effect of experiment time, shortening temperature rise time and stabilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

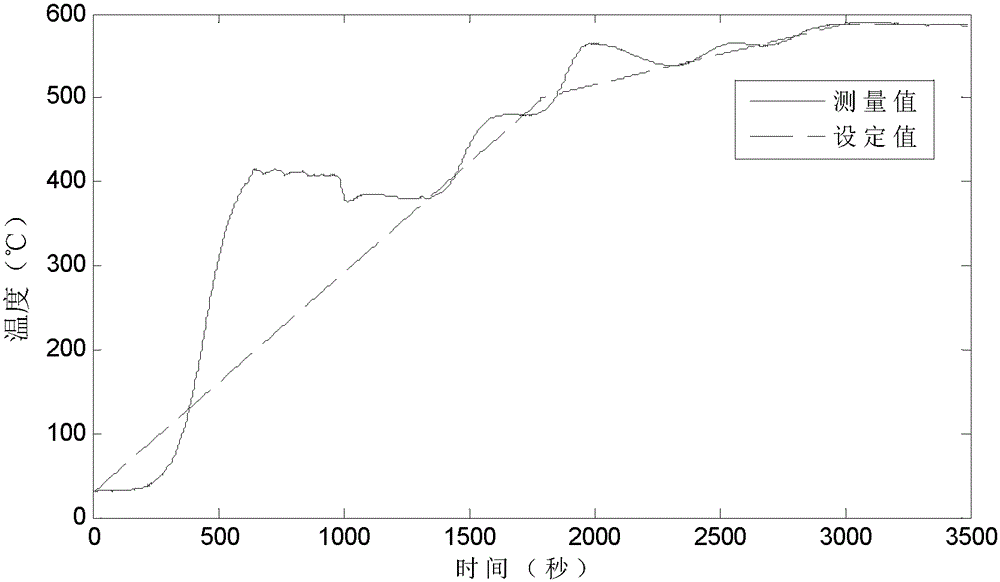

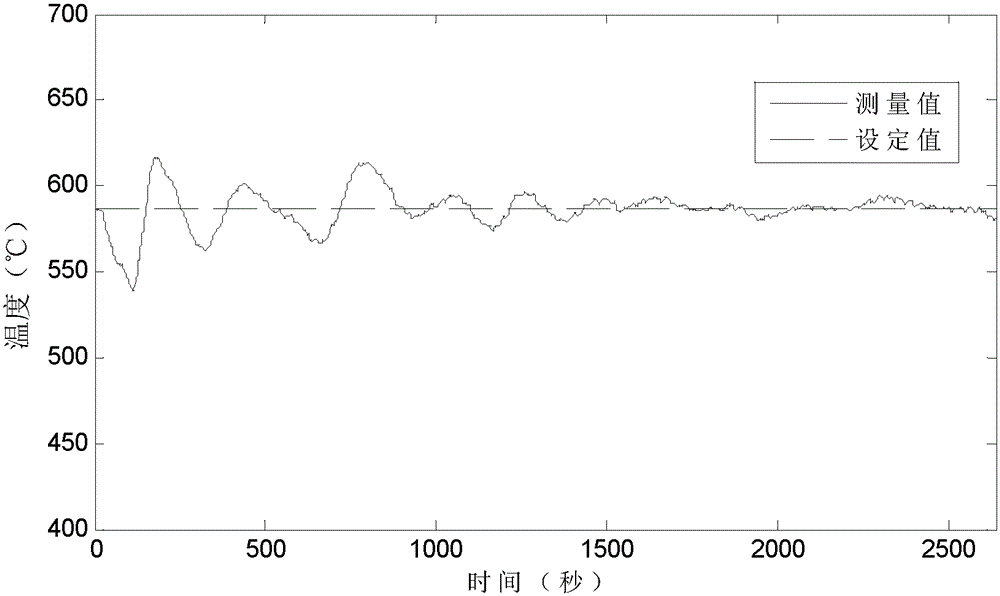

Examples

Embodiment Construction

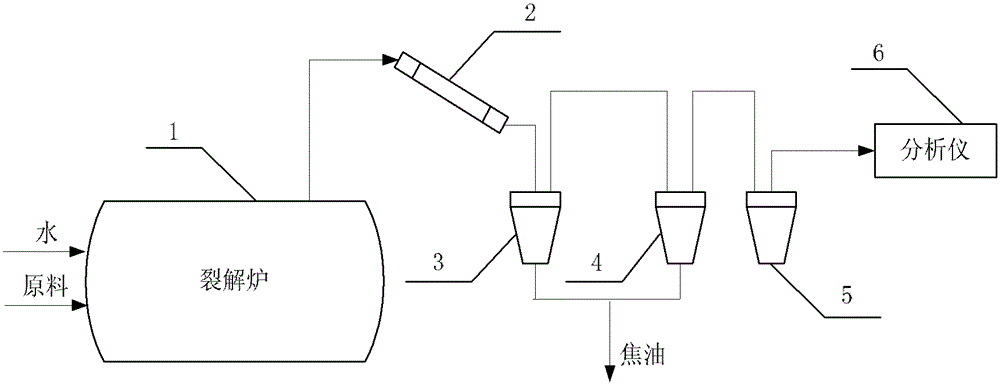

[0023] The control system and control method for controlling the reaction temperature of the cracking furnace according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] like Figure 4 As shown, the control system for controlling the reaction temperature of the cracking furnace according to the present invention includes a temperature acquisition module 401 and a two-degree-of-freedom internal model controller 402, wherein: the temperature acquisition module 401 is used to collect the current temperature of the cracking furnace and collect The current temperature obtained is transmitted to the two-degree-of-freedom internal model controller 402; the two-degree-of-freedom internal model controller 402 is used to adjust the heating of the cracking furnace according to the temperature setting value and the current temperature of the cracking furnace The heating power of the device is used to control the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com