Pressure control device

A technology of pressure control and housing, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of affecting the working life of pressure switches, slow contact closure and disconnection, contact closure and disconnection, etc., to reduce sparks and arcs The effect of producing, improving working life and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

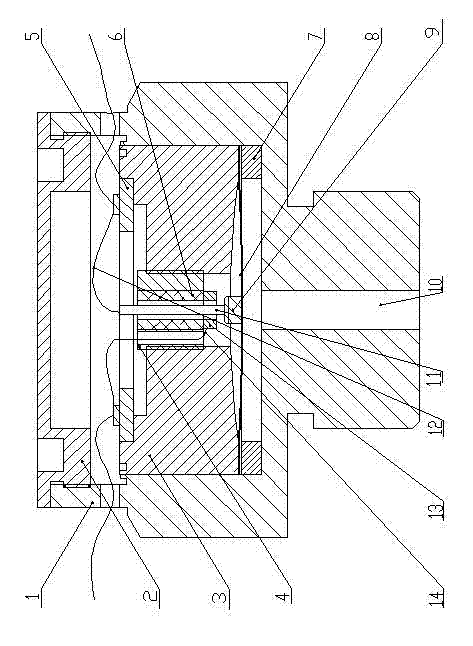

[0017] as attached figure 1 As shown: the pressure control device of the present invention includes: a housing 1 and an upper cover 2 connected to the housing, a fixing seat 3 with a circular arc contact surface is installed in the housing, and an adjustment terminal is installed on the fixing seat 4 and an adapter plate 5, a set of jumping diaphragms 8 are installed on the housing, a ceramic ring 6 is installed in the middle of the adjustment terminal, a backing ring 7 is installed in the housing, and a jumping ring is installed on the backing ring Diaphragm, the lower electrode 9 is installed on the jumping diaphragm, the copper wire 11 of the lower electrode passes through the central hole of the adjustment terminal, and the wire 12 is drawn out from the upper end of the copper wire to connect to the transfer The upper electrode 13 is installed under the adjustment terminal, and the lead wire 14 of the upper electrode passes through the side hole of the adjustment terminal ...

Embodiment 2

[0019] In the pressure control device, the bottom surface of the fixing seat has a circular arc structure.

Embodiment 3

[0021] In the pressure control device, there is an air inlet or liquid inlet hole 10 under the housing.

[0022] work process:

[0023] The measured gas or liquid enters the pressure control switch from the inlet (liquid) hole, and the pressure acts on the convex surface of the jumping diaphragm. When the pressure value reaches (exceeds) the jumping critical point of the jumping diaphragm, the jumping diaphragm generates a jumping, that is, the original convex surface is instantly depressed, the original concave surface is raised, and the lower electrode is displaced with the deformation of the jumping diaphragm, and the upper electrode The contact conducts, and the switch is closed instantaneously; when the pressure value falls back (lower) to the rebound critical point of the jumping diaphragm, the jumping diaphragm rebounds, and the switch is disconnected instantaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com