Mechanical transmission safety protection device for electric suction apparatus

A safety protection device and mechanical transmission technology, which is applied in the field of medical equipment, can solve the problems of burning out the vacuum pump, liquid entering the machine, and the inaccurate effect of the overflow protection device, so as to protect the machine, avoid blockage, and have high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by way of examples, but the present invention will not be limited in any way.

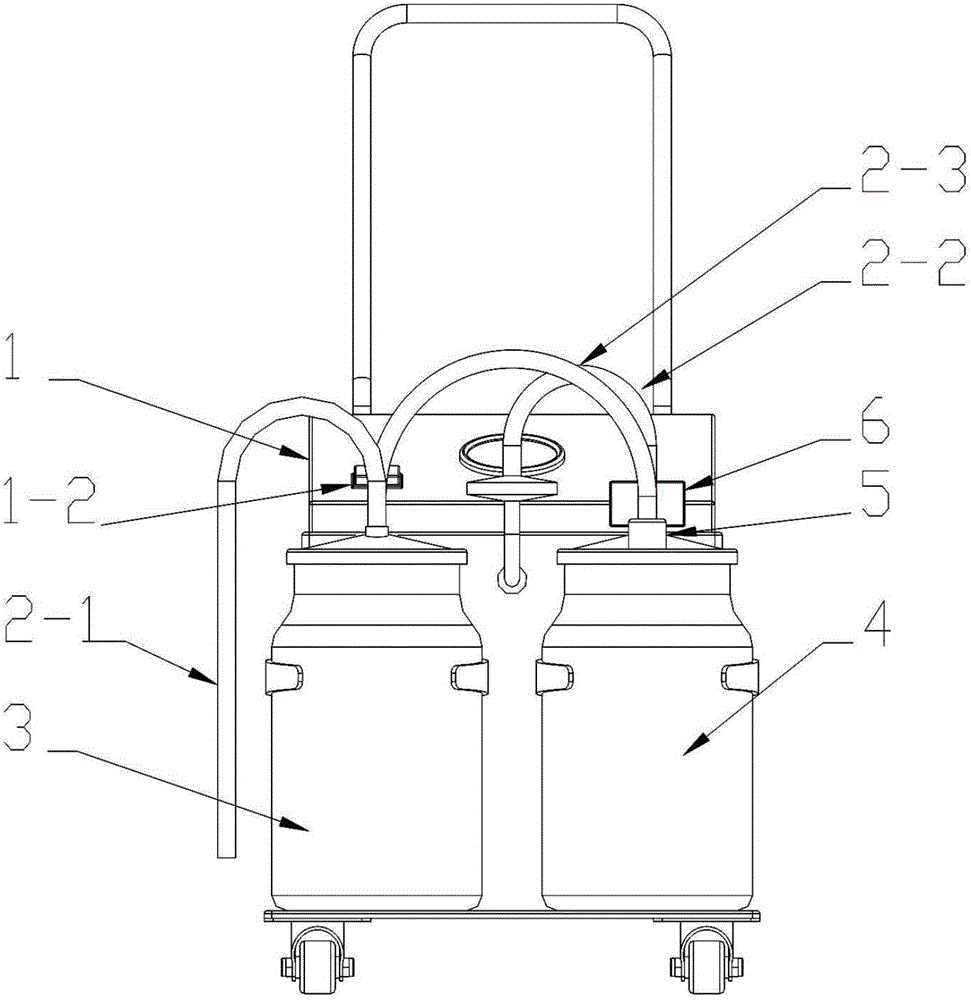

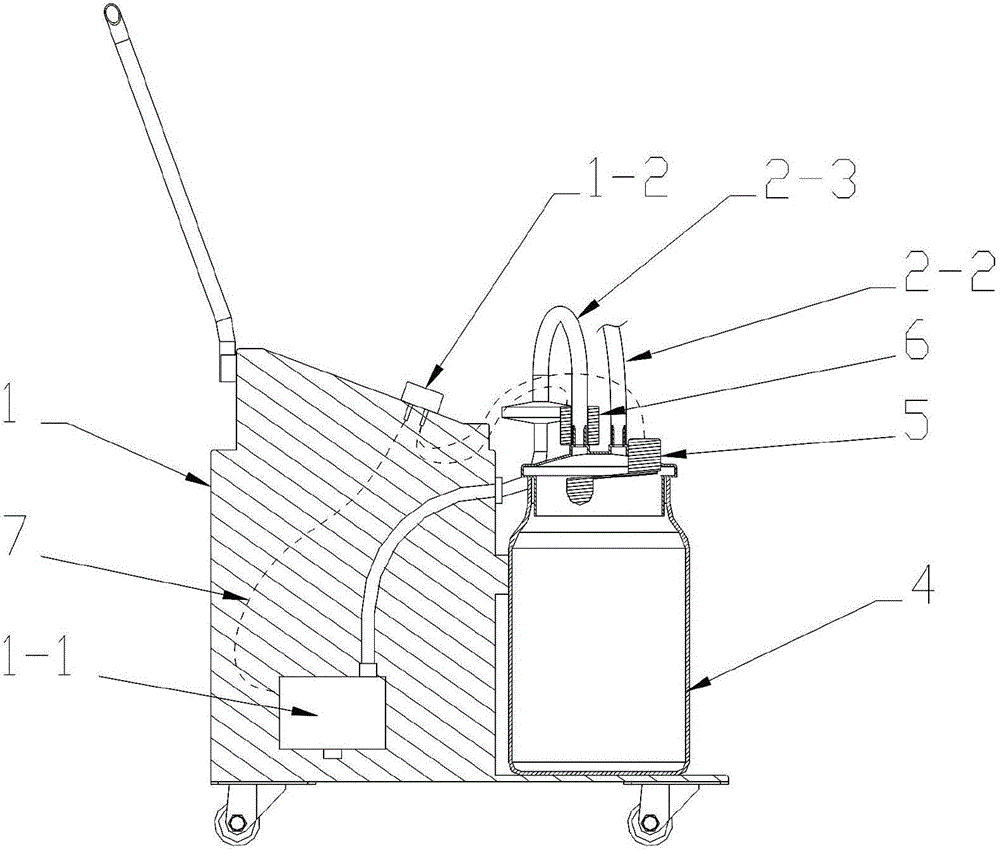

[0018] Such as Figure 1-2 As shown, the first storage bottle (3) is placed on the left side of the front platform of the electric suction device main body (1), and the second storage bottle (4) is placed on the right side of the platform. One end of the first silicone straw (2-1) is exposed, and the other end is exposed. Connect with the first storage bottle (3), the second silicone straw (2-2) connects the first storage bottle (3) with the second storage bottle (4), the third silicone straw (2-3) connects with the first Two storage bottles (4) are connected, and the other end is connected to the vacuum pump (1-1) inside the main body (1) of the electric suction device. We installed a float power-off device (5) on the cap of the storage bottle (4) to Monitor the liquid level of the second storage bottle (4), and control the main switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com