PBMC separation device and method

A separation device and separation liquid technology, applied in the field of biomedicine, can solve problems such as differences in separation quality, and achieve the effects of high separation efficiency, high separation accuracy, and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

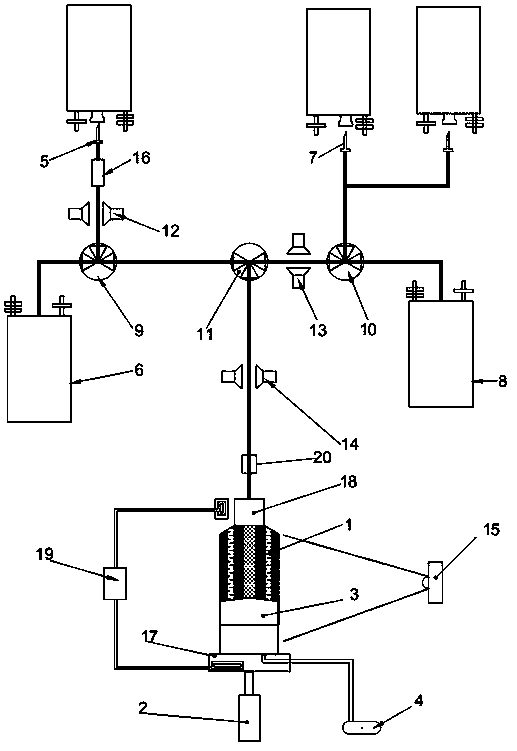

[0034] Specific embodiment one: a kind of PBMC separating device, it comprises controller, centrifugal barrel 1, the first power mechanism that is used to drive centrifugal barrel 1 to rotate, is arranged on the piston 3 in centrifugal barrel 1, is used to drive piston 3 in centrifugal The second power mechanism moving vertically in the barrel 1, the blood sample collection head 5, the separation liquid waste liquid container 6, the cleaning liquid collection head 7, the product collection container 8, the first three-way valve 9, the second three-way valve 10, the first three-way valve Three-way valve 11, the first photoelectric through-beam sensor 12, the second photoelectric over-beam sensor 13, the third photoelectric through-beam sensor 14, the ultrasonic flow sensor 20 and the camera 15 for detecting the position of the piston 3 in the centrifuge barrel 1, so The blood sample collection head 5 and the separation liquid waste liquid container 6 are all connected with the f...

specific Embodiment 2

[0046] The difference between the second embodiment and the first embodiment is that the second embodiment also includes a cooling mechanism 19, mainly to set cooling blocks on the rotating head 18 and the rotating platform 17 to cool the corresponding areas.

specific Embodiment 3

[0047] The third embodiment differs from the first embodiment in that an observation drip 16 is set between the blood sample collection head 5 and the first three-way valve 9 in the third embodiment, which is convenient for the user to observe the blood sample collection and observe the drip 16. There is also a filter mechanism for filtering blood clots.

[0048] The control method of above-mentioned device, it comprises the following steps:

[0049] S1. Connect the blood collection bag with 100ml of blood sample and the cleaning solution bag with 500ml of cleaning solution to the blood sample collection head and the cleaning solution collection head respectively, and inject 100ml of separation liquid into the separation liquid waste container; the separation liquid It is ficoll (the brand is GE, the product number is 17-1440-03), and the cleaning solution is normal saline;

[0050] S2, the centrifuge bucket rotates with a centrifugal force of 800xg, and simultaneously inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com