Accurate butt-joint device for automatic clamping of pipeline and movable butt-joint device

A docking device and automatic clamping technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of weak anti-interference ability, difficult to meet accurate positioning, and insufficient positioning accuracy, so as to reduce investment costs and adapt well High performance and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

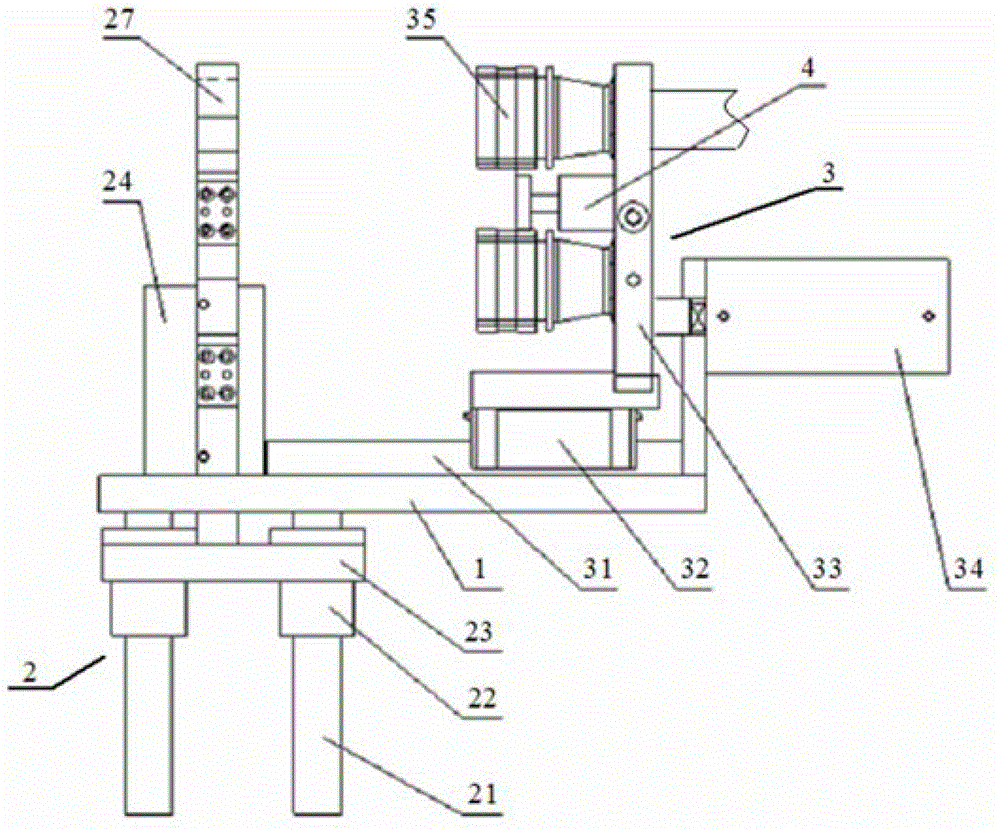

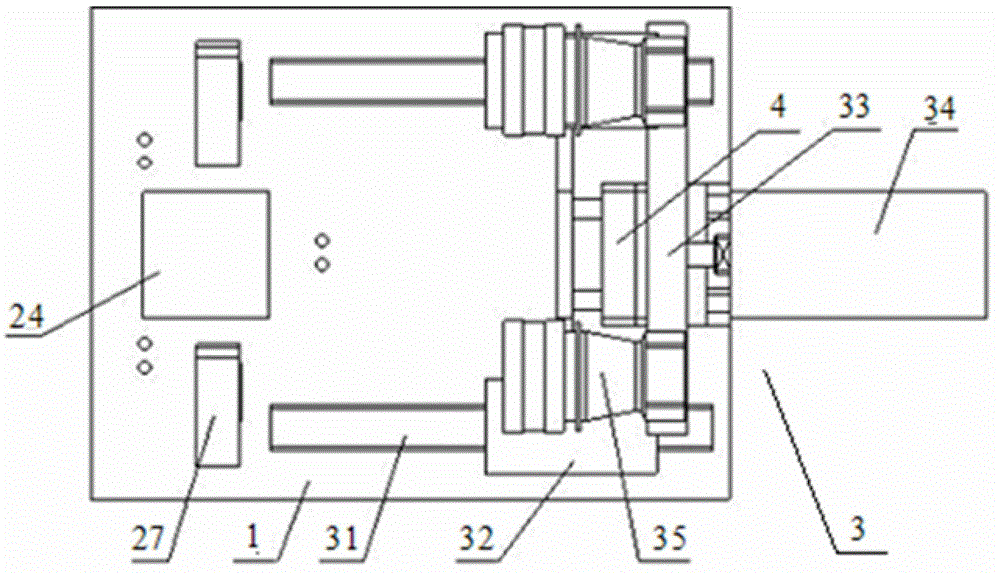

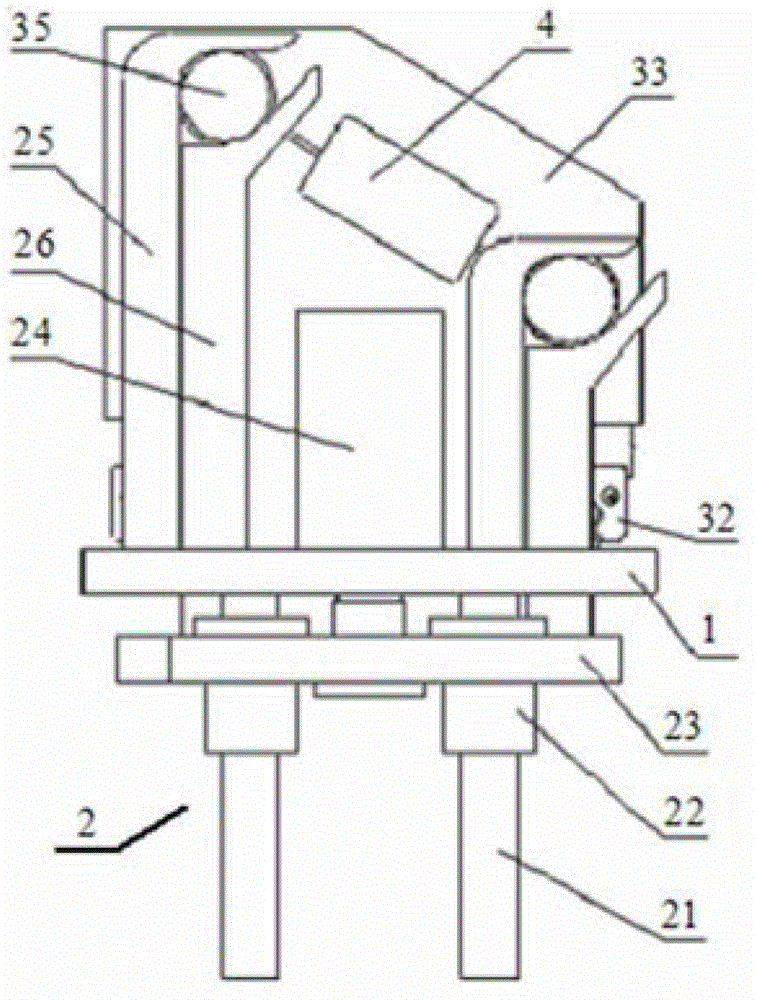

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or replacements made according to the teaching of the present invention belong to the protection scope of the present invention.

[0018] Such as Figure 1~3 As shown, the pipeline automatic clamping and precise docking device of the present invention includes a frame 1, a clamping mechanism 2, a pipeline joint moving mechanism 3, and a pipeline butt joint 35. The clamping mechanism 2 and the pipeline joint moving mechanism 3 are installed on the machine On the rack 1, the clamping mechanism 2 locates and clamps the moving pipeline joint at the moving end, and the pipeline joint moving mechanism 3 drives the pipeline joint 35 to move horizontally relative to the pipeline.

[0019] Described clamping mechanism 2 comprises guide rod 21, guide sleeve 22, positioning plate 23, clamping mechanism 24, fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com