High-molecular composite material telescopic processing mold

A technology for processing molds and composite materials, applied in the field of processing molds for polymer composite materials, can solve the problems of inability to reuse and scrap, and achieve the effects of simple structure, convenient manufacturing and easy demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 is the telescopic processing mold of polymer composite material

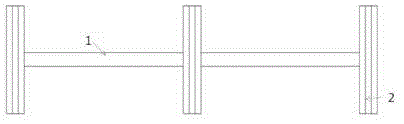

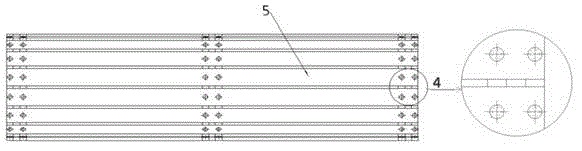

[0026] Such as figure 1 , figure 2 As shown, on a thinner mandrel 1, there are three telescopic rings 3 perpendicular to the mandrel. The front view of the telescopic ring is as follows: figure 2 As shown, the top of the radial telescopic rod 2 is connected to the parallelogram, and is connected to the metal sheet 5 through the hinge 4 around the parallelogram, so that the metal sheet fully covers the telescopic processing mold 6; the telescopic mold end cover is designed according to the principle of an umbrella. The second 7 is provided with a drive ring 8, the drive ring is connected with the radial telescopic rod two 9, and the radial telescopic rod two is connected with a plurality of telescopic brackets 10 on the end cover surface, and the support is also covered with sheet metal to form a complete end cover mould.

Embodiment 2

[0027] Embodiment 2 is the pipeline expansion and contraction processing mold of polymer composite material

[0028] Such as image 3 As shown, when the three telescopic rings 3 are fixed, the pipe diameter of the telescopic processing mold 6 will no longer change, and the top of the radial telescopic rod 2 must cover the metal sheet 5 connected with the hinge 4, and be concentrically wound on the telescopic ring 3, thereby obtaining Complete telescoping tooling. Regardless of whether the diameter of the pipe is growing or shrinking, the change in the circumference of the pipe can be achieved by connecting different numbers of metal sheets. After the preparation of the composite material pipe is completed, the telescopic ring is lowered, the diameter becomes smaller, and demoulding will be very easy.

Embodiment 3

[0029] Embodiment 3 is a tapered pipeline telescopic processing mold of a polymer composite material

[0030] Such as Figure 5 As shown, when the three telescopic rings 3 can be enlarged or reduced synchronously, a pipe mold with the same diameter can be obtained. However, the size of the three telescopic rings can also vary inconsistently, so that a tapered pipe telescopic processing mold can be obtained. When the diameter of the telescopic ring 1 is a little smaller, the diameter of the telescopic ring 2 is slightly larger, and the diameter of the telescopic ring 3 is the largest, and then covered with a metal sheet, then a telescopic processing mold with a taper will be obtained, which can be expected to be used in the production of electric poles and towers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com