Hot forming die with combined cooling female die and changeable movable base plate

A technology of movable backing plate and die backing plate, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low cooling efficiency, uneven cooling, small cooling area, etc., achieve uniform cooling and improve utilization rate , the effect of increasing the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

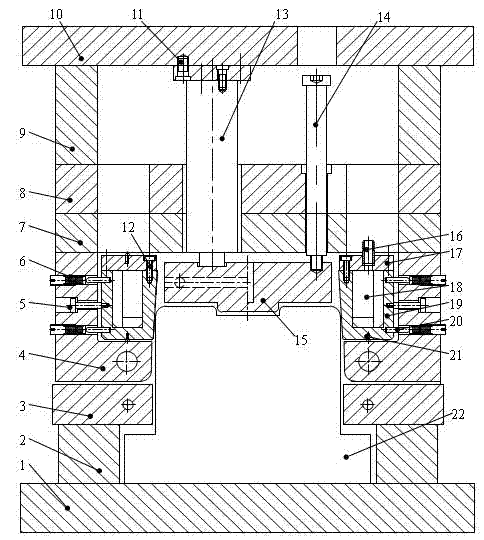

[0021] The specific structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

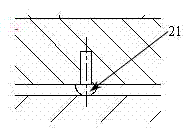

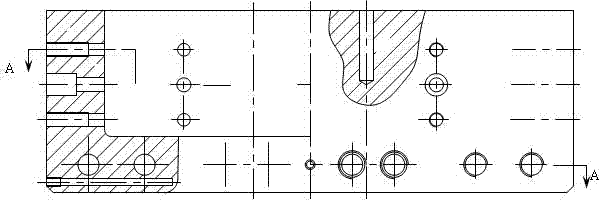

[0022] Depend on figure 1 As shown, the present invention provides a thermoforming die with a combined cooling die and a replaceable movable backing plate. The thermoforming die adopts an inverted structure and consists of two parts, an upper and an lower die. Die 4, die backing plate 7, upper die base 8, upper die backing plate 10, nitrogen spring assembly 13, movable backing plate 15 and movable cooling block 19, water guide plate 18, cooling block cover plate 17; It is partly composed of a lower die base 1, a pier dead block 2, a blank holder 3 and a punch 22. The upper die part is installed on the upper slider of the press, and the lower die part is installed on the workbench of the press. During stamping, the high-temperature sheet is located between the upper and lower dies, and the die and die backing plate are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com