Temperature-sensitive print head

A thermal print head and heating resistor technology, applied in printing, electrical components, image communication, etc., to prevent electrostatic damage and reduce charge accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Implementation form 1:

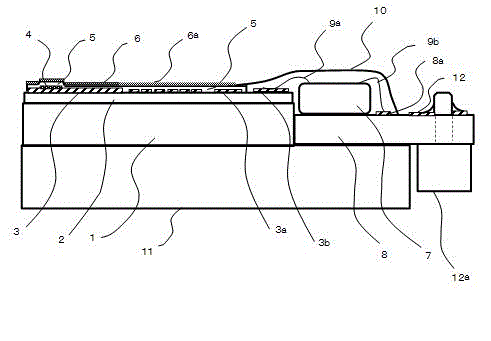

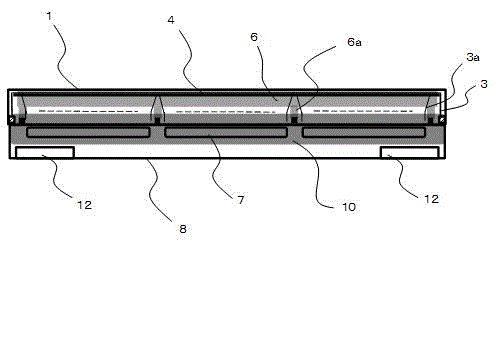

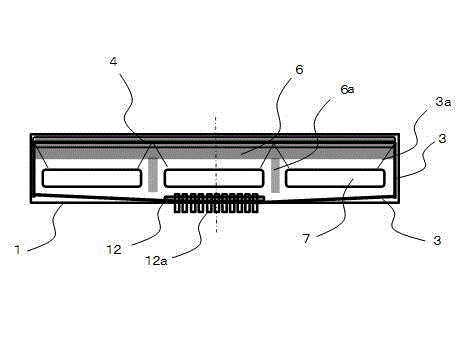

[0019] refer to figure 1 Embodiment 1 of the present invention will be described. figure 1 It is a cross-sectional view of a thermal print head according to Embodiment 1. On the surface of an insulating substrate 1 such as a ceramic substrate, an amorphous glass paste 2 is partially or completely coated to form a smooth fine pattern, and then Forming the conductor pattern 3 and the heating resistor body layer 4, the conductor pattern 3 can be printed, sintered, photolithography and other graphic plate-making techniques, using gold paste to form the electrode lead-out pattern 3a and the bonding pad pattern 3b on the surface of the insulating substrate 1 Wait. The heating resistor 4 is formed by linearly printing and sintering the resistive paste along the direction of the recording web, and is connected to the conductor pattern 3 for supplying applied power as a heating unit for generating Joule heat.

[0020] Cover the surface of the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com