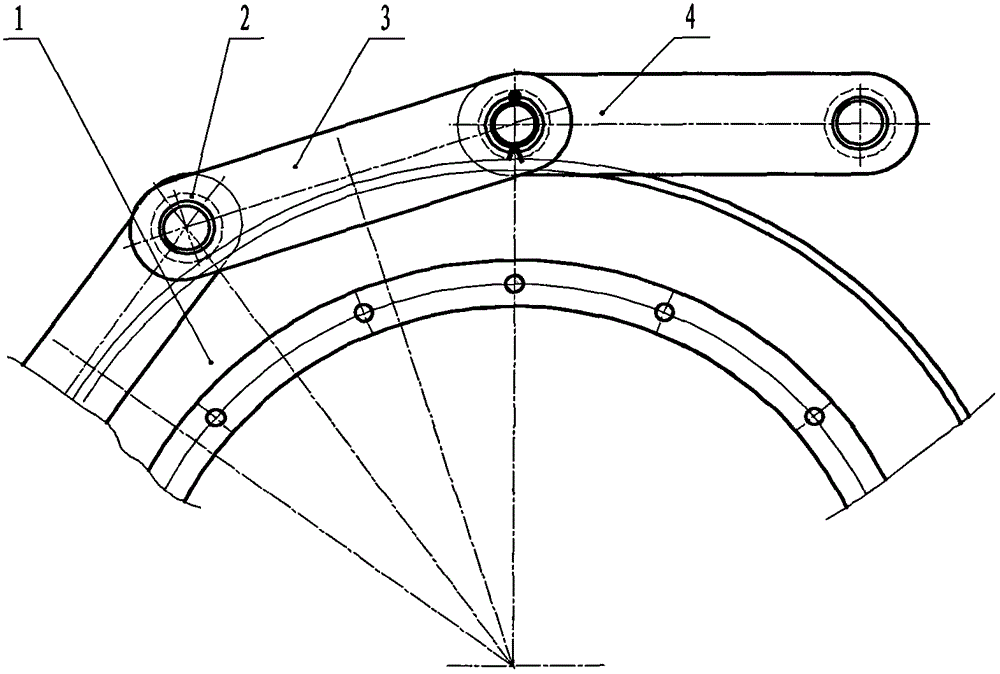

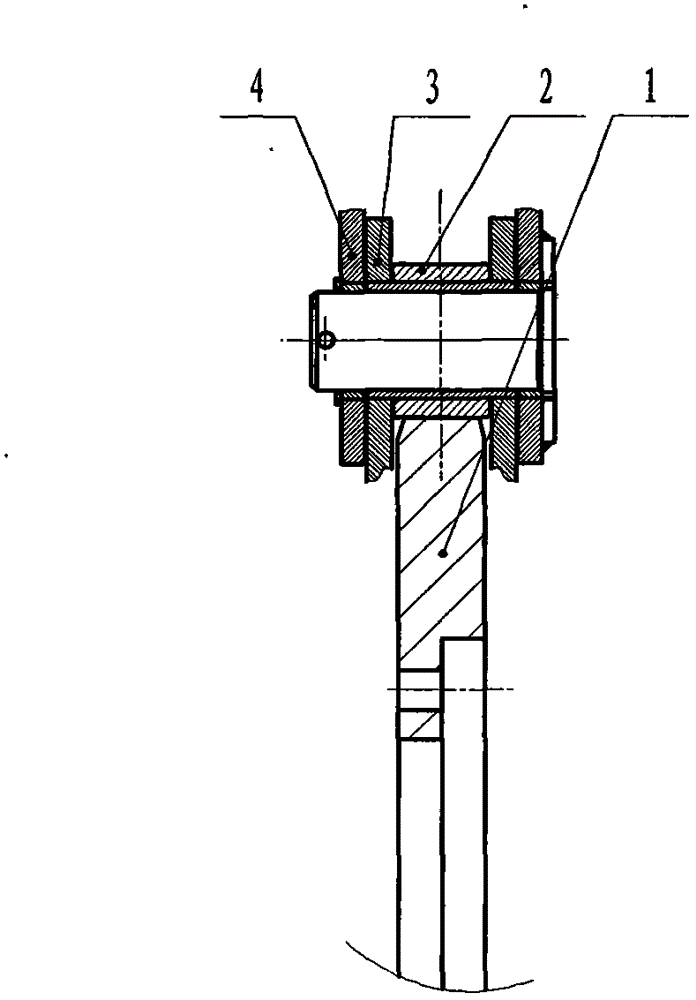

Tail pulley chain device for hot ore chain scraper conveyor

A technology of chain-plate conveyor and tail wheel, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of high cost, stuck chain, climbing chain, etc., and achieve the effect of low cost, simple and reliable structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The chain-plate conveyor is generally installed on a slope with a certain inclination angle. The motor reducer drives the head wheel to rotate, and then the head wheel drives the chain, and the chain drives the tail wheel. The hopper is installed on the chain, and the hopper and the chain move together. The tail of the chain plate conveyor is used for the hopper to turn and carry the hopper at the turn at the tail. Part 1: There are no teeth on the sprocket of the tail wheel. At the turn at the tail, the outer circle of the sprocket of the tail wheel is tangent to the outer circle of the roller on the chain, so that the distance between the center of the sprocket and the roller remains unchanged. The sprocket of the tail wheel is on the chain Between the chain plates, the chain is prevented from moving along the axis of the tail wheel shaft, which ensures that the chain plate conveyor is used to turn the hopper at the tail and carry the hopper; the hubs and shafts at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com