Method for determining the minimum design operating pressure of underground salt cavern gas storage

A technology of operating pressure and determination method, applied in mining equipment, earthwork drilling, mining equipment and other directions, to achieve the effect of simple steps, clear mechanical mechanism, and strong engineering use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

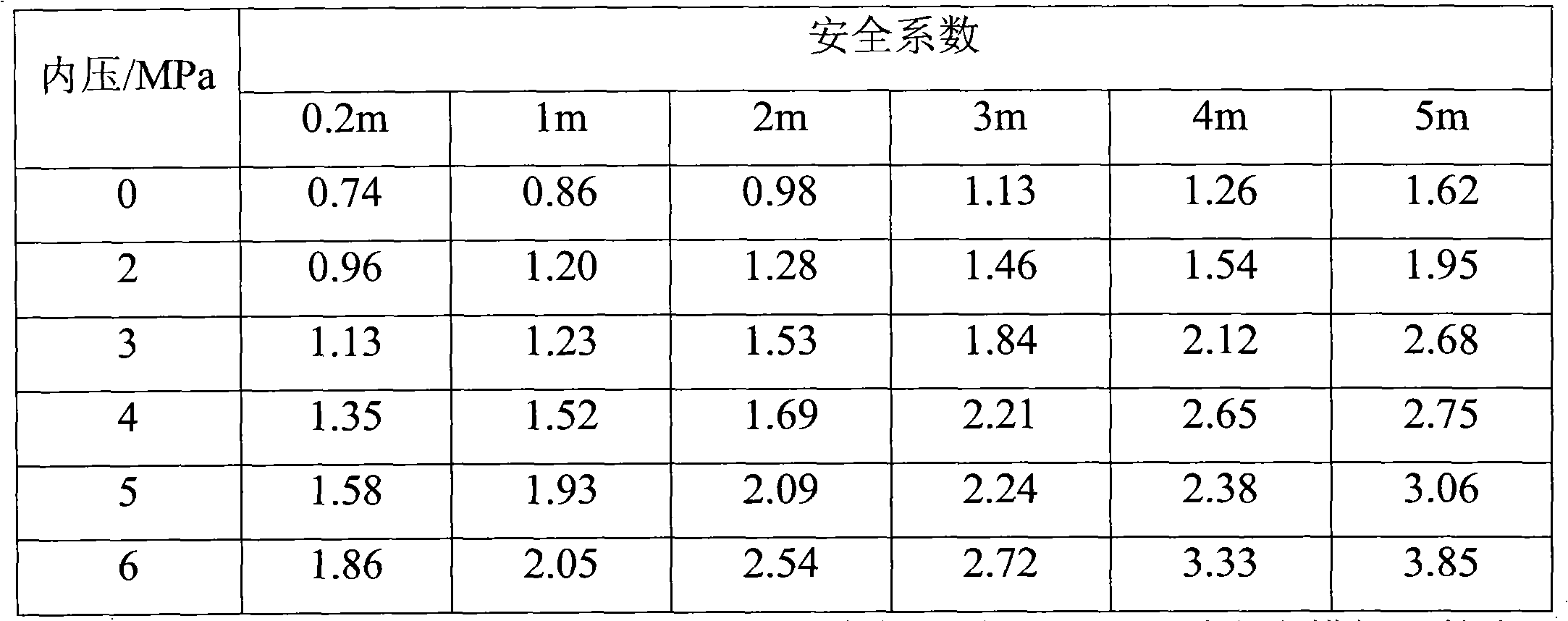

[0022] A proposed salt cavern gas storage is located in the target salt rock layer with a buried depth of 1000-1255m. There are many interlayers in the salt rock layer, and the interlayer components are mainly anhydrite, mudstone and glauberite. The method for determining the minimum design operating pressure of an underground salt-cavern gas storage is described below by taking one of the salt-cavern gas storages as an example.

[0023] The specific steps of the method for determining the minimum design operating pressure of underground salt cavern gas storage include:

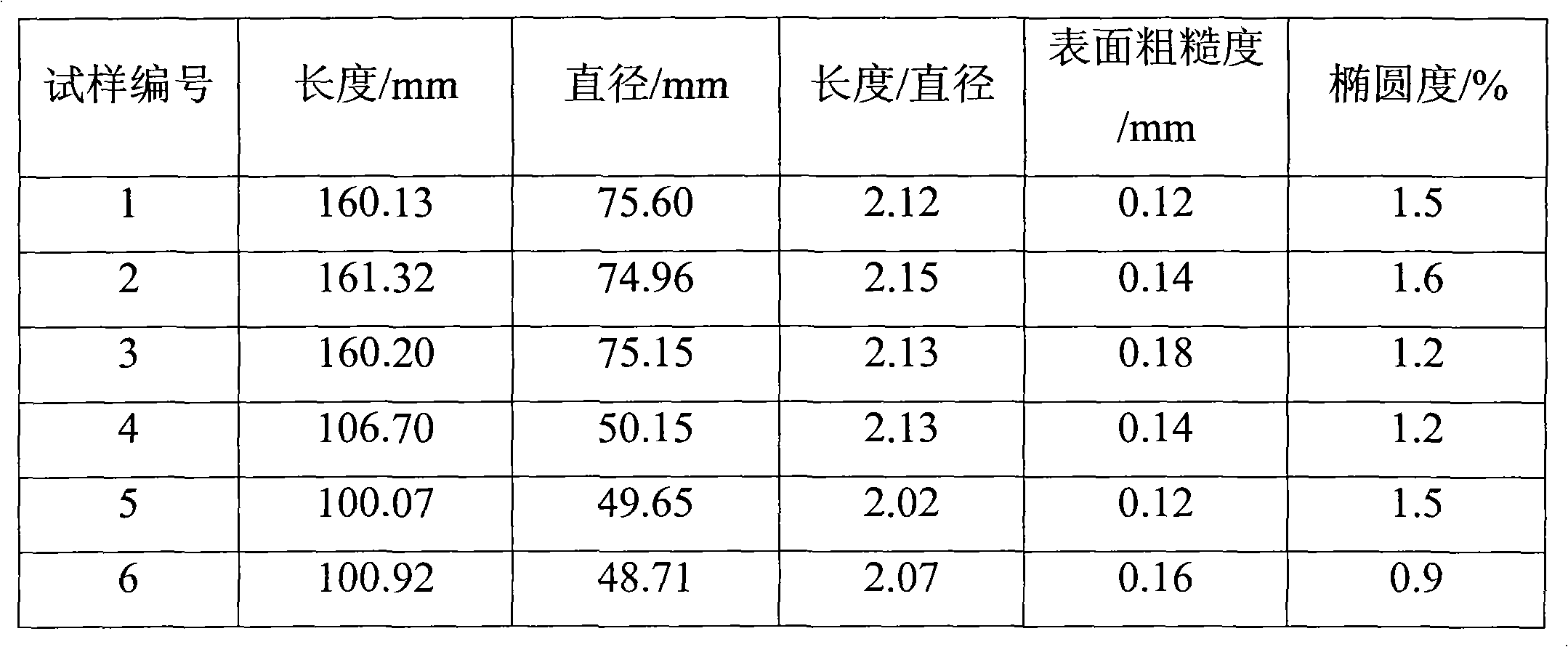

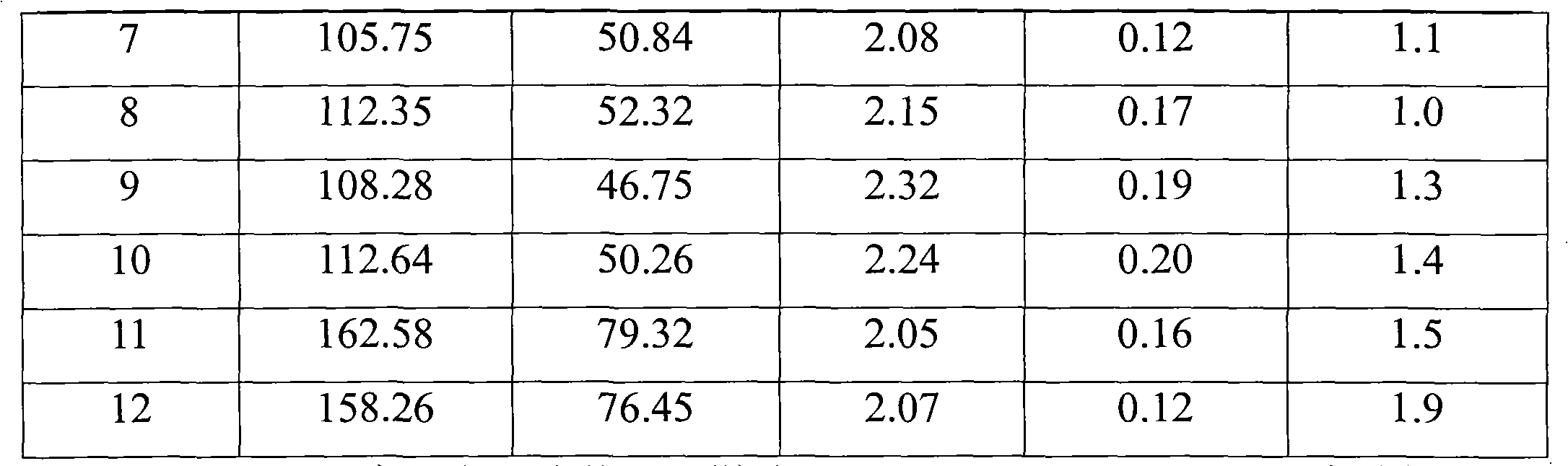

[0024] (1) Production of salt rock samples: According to on-site drilling and coring, the salt rock samples in the target salt rock stratum of the salt cavern gas storage were obtained. In order to avoid water damage to the salt rock structure during the processing of the specimens, dry The sawing and grinding method is used to process the standard test piece; firstly, the rock sample is manually cut into sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com