Multi-combustion type civil heating furnace integrating direct firing, return firing and gasified combustion

A technology for heating furnaces and back-burning, which is applied to household furnaces/stoves, furnaces/stoves with hot water devices, applications, etc., which can solve problems such as environmental pollution, resource waste, and insufficient heating area, and reduce dust pollution , Reduce flue gas emissions, improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

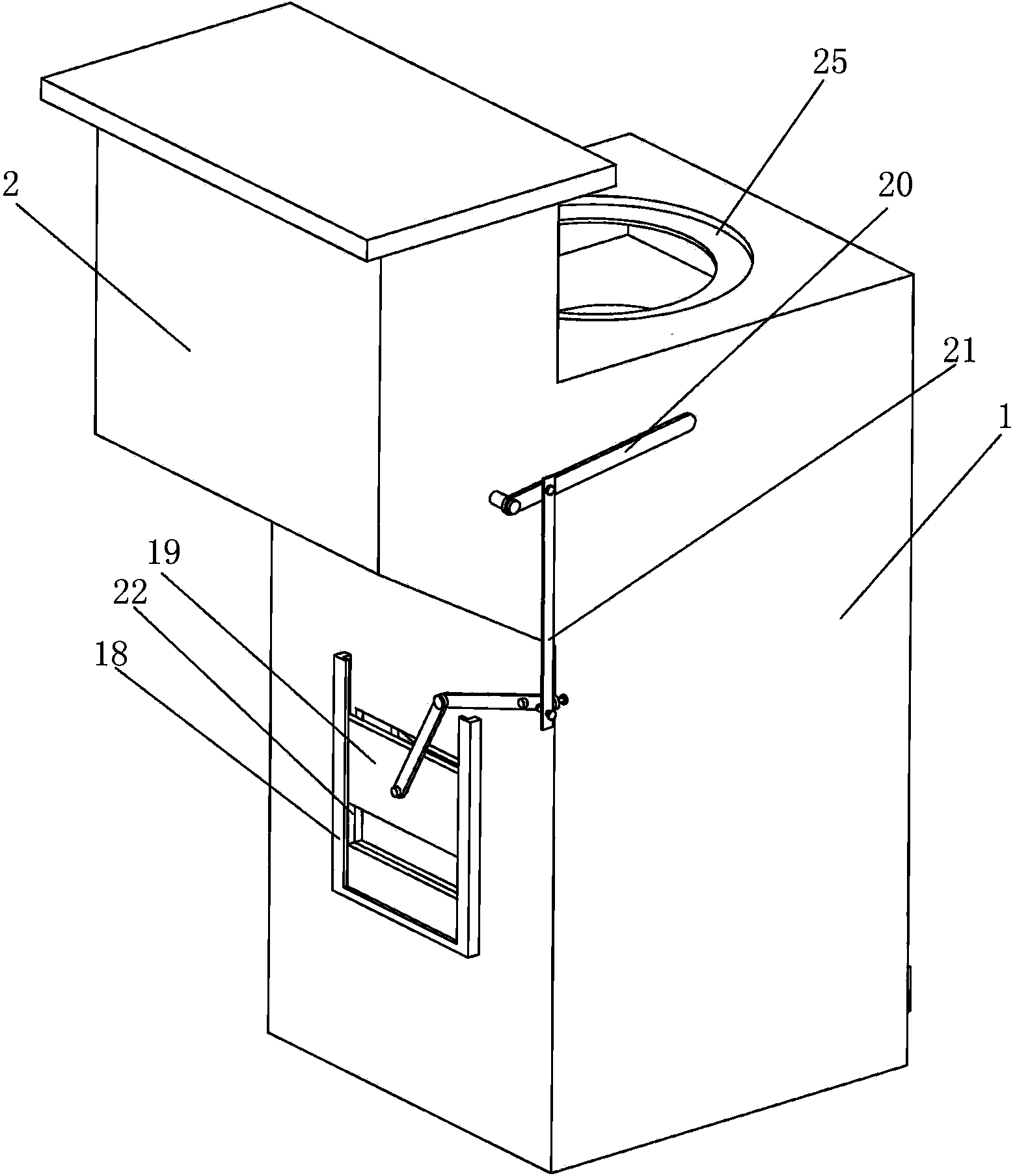

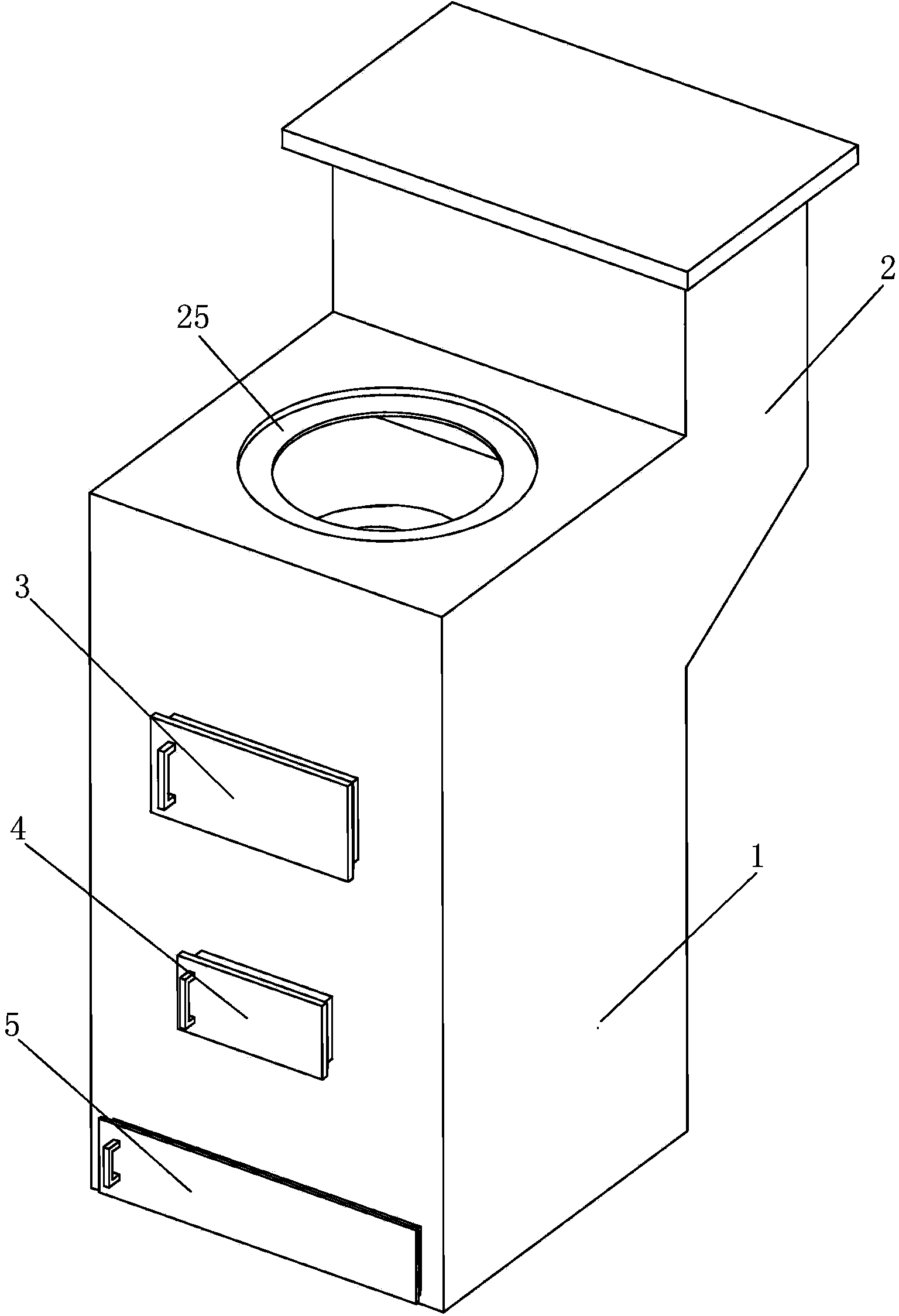

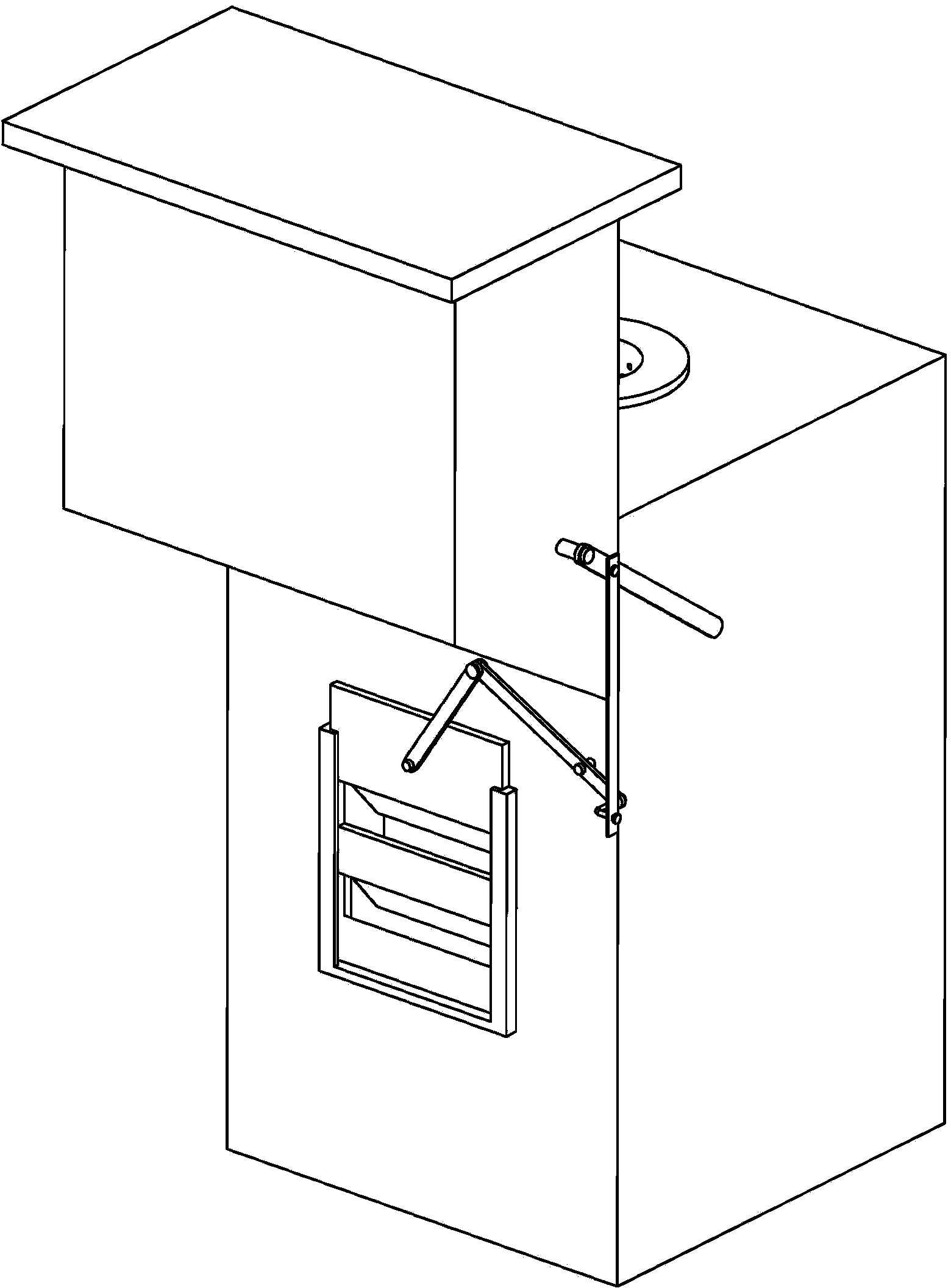

[0031] as attached Figure 1-7 As shown, the present invention is a multi-combustion civil heating furnace integrating direct combustion, back-firing and gasification combustion. It includes a furnace body 1 and an expansion water tank 2. The front end of the furnace body 1 is sequentially arranged with Coal filling port 3, front air door 4 and slag removal door 5, the upper end of the furnace body 1 is provided with a first furnace port 24, which is characterized in that the second furnace port 25 arranged at the upper end of the first furnace port 24 is embedded in the second furnace port A porous cylindrical inner interlayer combustion-supporting device 6 in the furnace mouth 24, a high refractory tubular temperature increasing device 7 fixedly arranged at the lower end of the porous cylindrical inner interlayer combustion-supporting device 6, and an internal air blower installed in the furnace body 1. The airway system and the connecting rod type damper adjustment device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com