High molecular electric ground heating module with waterproofness, high temperature resistance and flame-retarding functions

A high-molecular, high-temperature-resistant technology, applied in electric heating systems, heating methods, household appliances, etc., can solve problems such as induced current, electromagnetic field is difficult to eliminate, cement base cannot be combined, and thermal effect time is long, etc., to achieve simple construction and small space occupation , the effect of uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

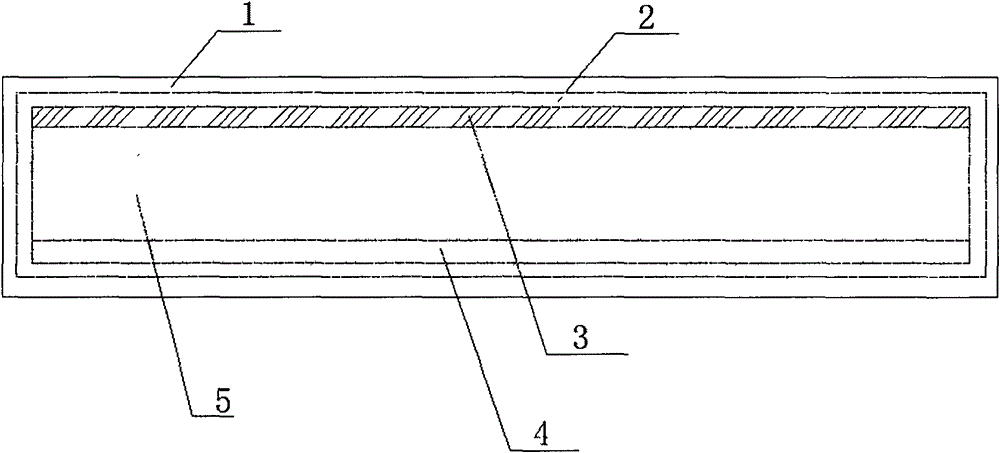

[0029] Such as figure 1 The embodiment shown is a polymer electric heating floor heating module with waterproof, high temperature resistance and flame retardant functions. On the outside of the non-woven fabric layer, the upper layer of the thermal insulation layer is a heating layer, the bottom of the thermal insulation layer is covered with a reflective film with pure metal aluminum foil, and the non-woven fabric layer is covered on the outside of the thermal insulation layer, the heating layer, and the reflective film.

[0030] The waterproof layer is made of cement-based polymer waterproof material, and non-woven fabric can be used as a reinforcing net to cover the inner surface, so as to prevent water infiltration and avoid safety accidents such as electric leakage.

[0031] The heating layer is a diaphragm made of polymer carbon fiber heating material, connected to two poles with 220V AC externally, and has the functions of heating and emitting far-infrared rays.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com