Continuous production line for gas meter and production process flow

A production process and gas meter technology, applied in the direction of liquid/fluid solid measurement, measuring devices, instruments, etc., can solve the problems of low production efficiency, long production cycle, large temperature difference, etc., to save detection time and improve detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

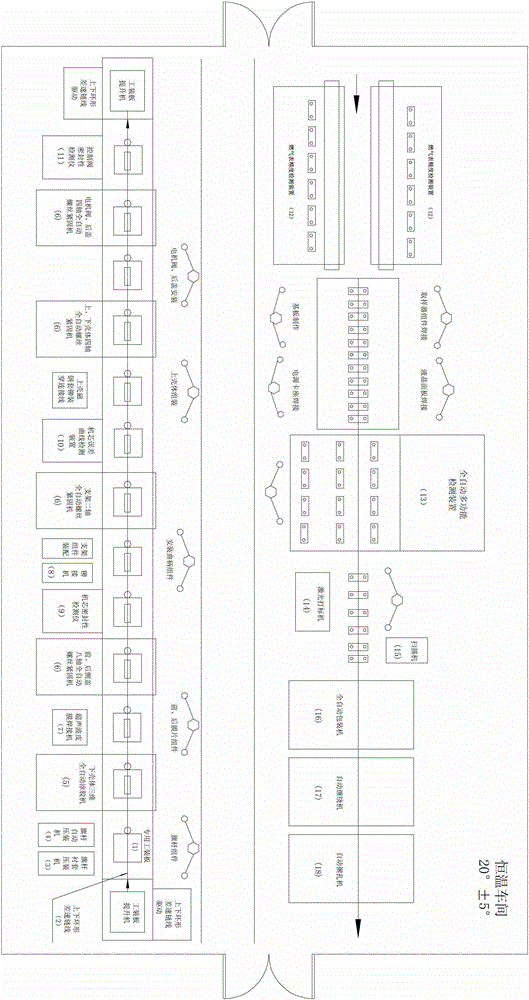

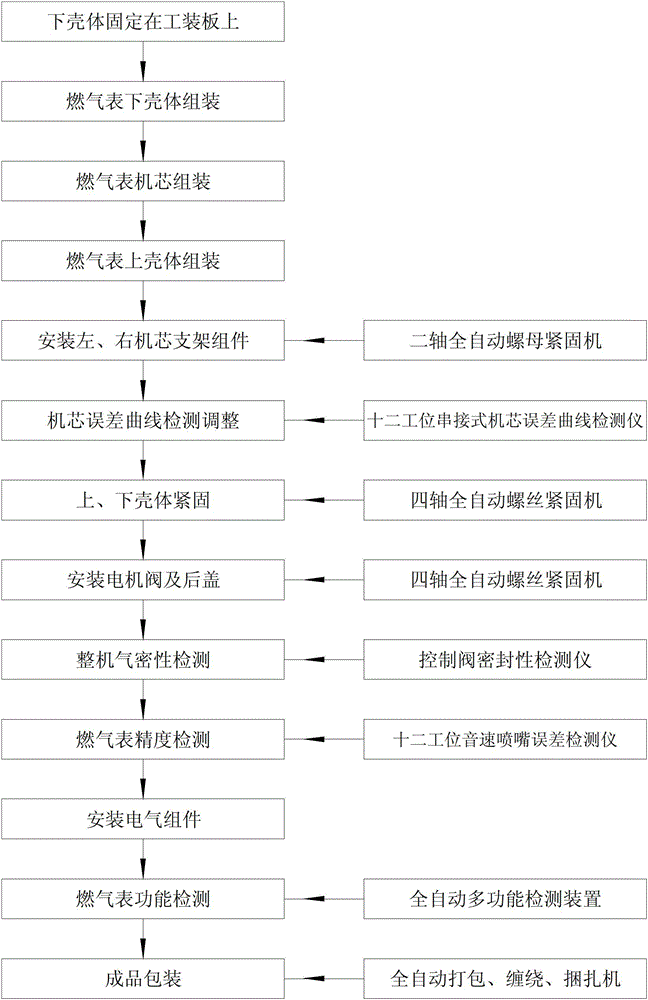

[0066] Embodiment: A continuous gas meter production line of this embodiment is set in a full constant temperature workshop, the temperature of the constant temperature workshop is 20±5°C, and the humidity is 65%±5%. figure 1 As shown, the production line includes:

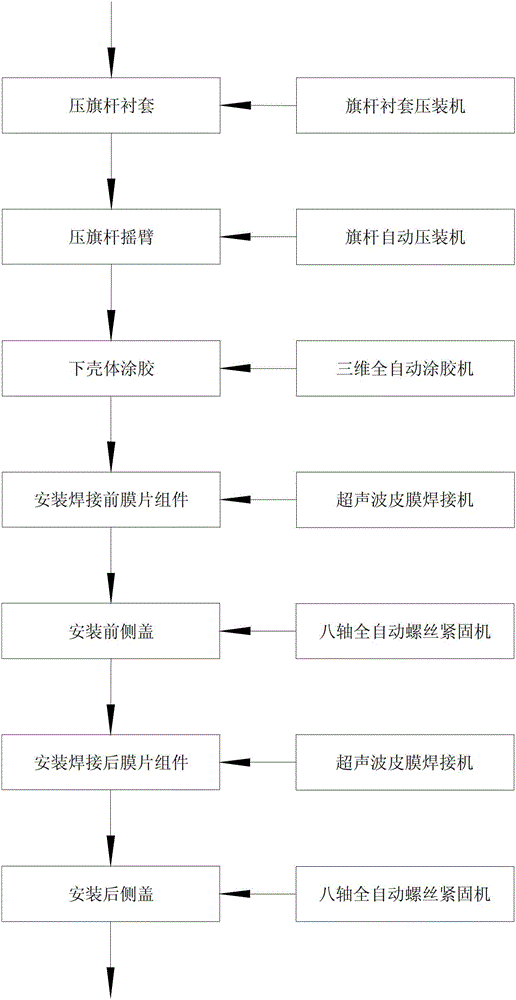

[0067] The assembly unit completes the assembly of the gas meter, including the special tooling plate for gas meters 1, the upper and lower annular differential chain lines 2, the flagpole bushing press machine 3, the flagpole automatic press machine 4, the three-dimensional automatic gluing machine 5, the multi-axis full Automatic screw fastening machine 6, ultrasonic film welding machine 7 and riveting machine 8, special tooling boards are installed on the upper and lower annular differential chain lines;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com