Insulation monitor for capacitive equalizing insulation core

A technology of capacitive voltage equalization and insulating core, which is applied in the direction of voltage divider, measuring current/voltage, instruments, etc., and can solve problems such as unsafe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

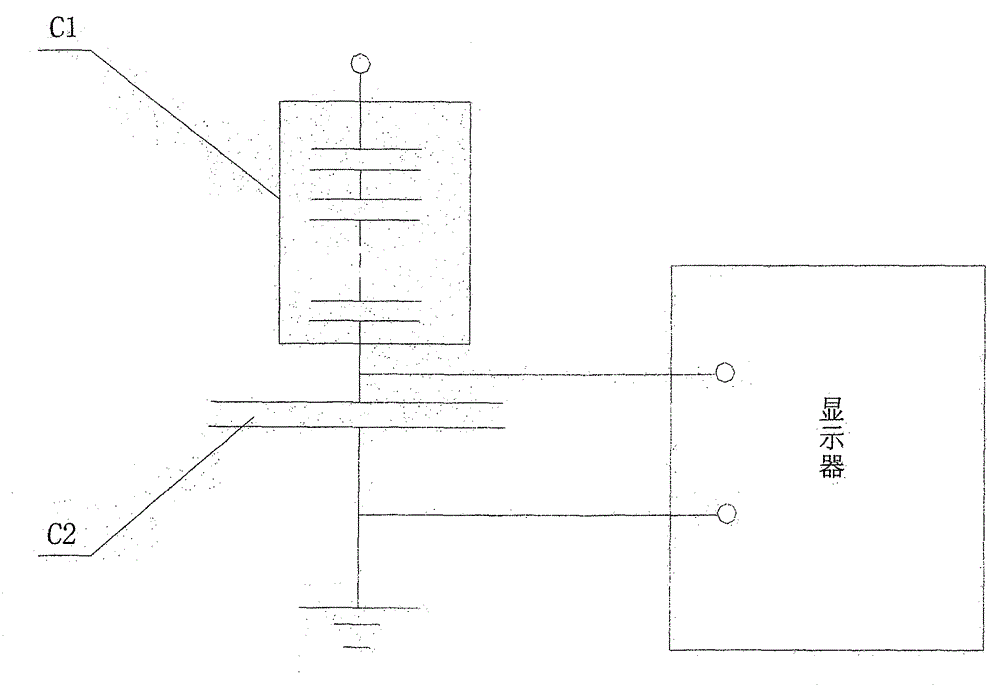

Embodiment approach 1

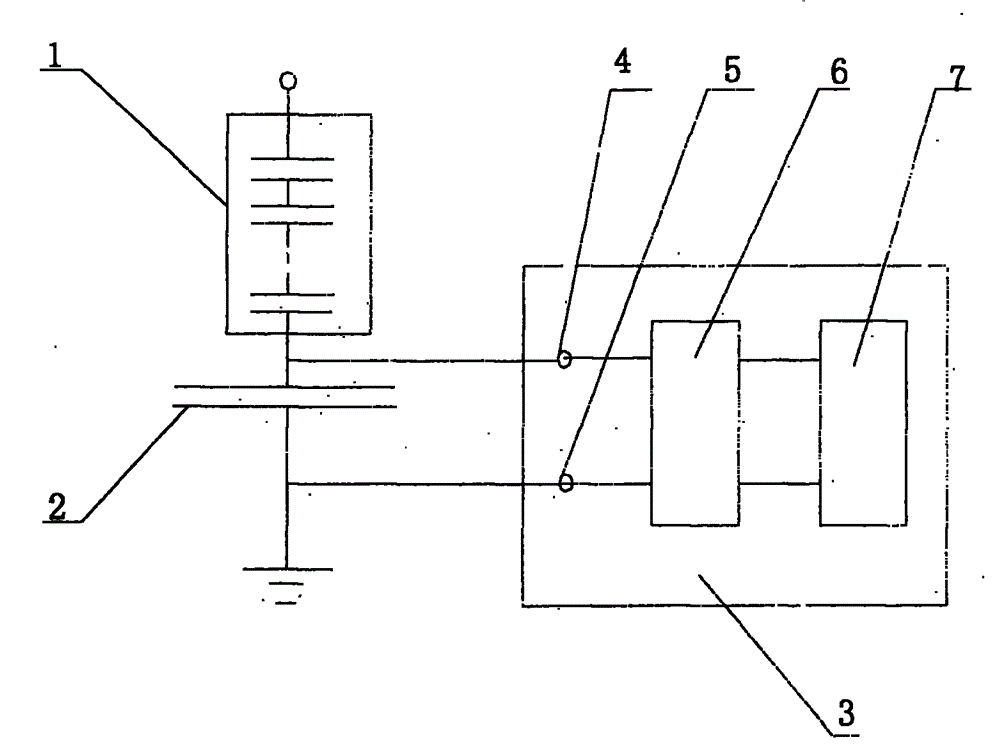

[0020] See figure 2 , the insulation monitor of the capacitor voltage equalizing insulating core is composed of a capacitor voltage equalizing insulating core 1, a low-voltage capacitor 2 and a display 3, and is composed of an insulating layer (such as polytetrafluoroethylene film, glass fiber impregnated with epoxy resin or oil paper insulation, etc.) ) and capacitive screens of conductive or semiconductive materials (such as aluminum foil, semiconductive tape, etc.) laid alternately (such as wrapping). The same process method is used to lay the insulating layer and the grounding screen outside the end screen of the capacitor voltage equalizing insulating core 1 (for example, insulating materials such as polytetrafluoroethylene film, epoxy resin impregnated glass fiber or oil paper insulation and aluminum foil or semi-conductive tape are still used. Alternately surrounded by equal-capacitance screens) to form a low-voltage capacitor 2, the monitoring terminal 4 is drawn out ...

Embodiment approach 2

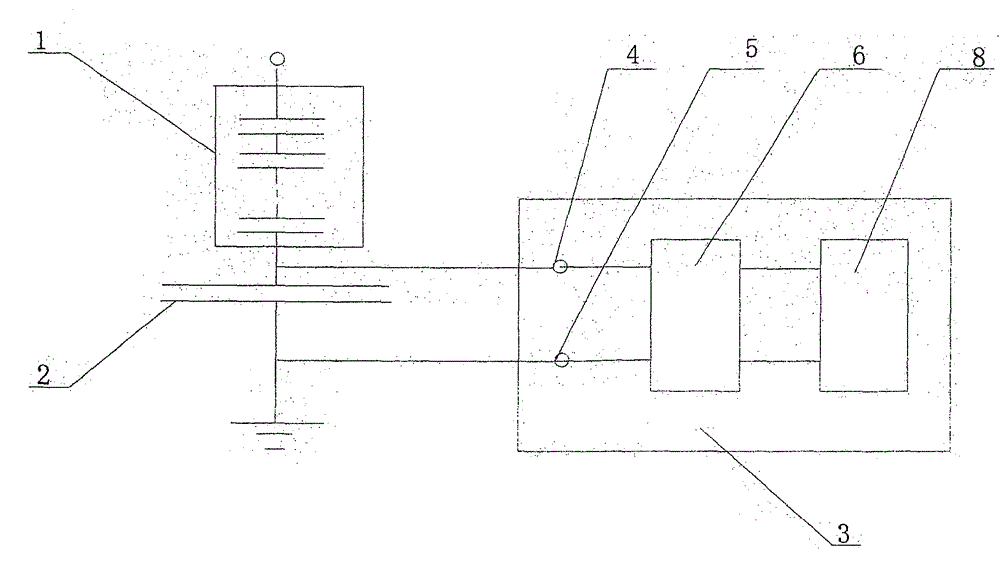

[0022] See image 3 , the insulation monitor of the capacitor voltage equalizing insulating core is composed of a capacitor voltage equalizing insulating core 1, a low-voltage capacitor 2 and a display 3, and is composed of an insulating layer (such as polytetrafluoroethylene film, glass fiber impregnated with epoxy resin or oil paper insulation, etc.) ) and capacitive screens of conductive or semi-conductive materials (such as aluminum foil, semi-conductive tape, etc.) are laid alternately (such as wrapping) to form the last screen of the capacitive voltage equalizing insulating core 1. (For example, polytetrafluoroethylene film, epoxy resin impregnated glass fiber or oil paper insulation and other insulating materials are alternately wrapped with capacitive screens such as aluminum foil or semi-conductive tape) to form a low-voltage capacitor 2. The connection point of the capacitor 2 leads to the monitoring terminal 4, and the monitoring terminal 4 and the grounding termina...

Embodiment approach 3

[0024] See Figure 4 , the insulation monitor of the capacitor voltage equalizing insulating core is composed of a capacitor voltage equalizing insulating core 1, a low-voltage capacitor 2 and a display 3, and is composed of an insulating layer (such as polytetrafluoroethylene film, glass fiber impregnated with epoxy resin or oil paper insulation, etc.) ) and capacitive screens of conductive or semi-conductive materials (such as aluminum foil, semi-conductive tape) are laid alternately to form the final screen of the capacitor voltage equalizing insulating core 1. Insulation materials such as vinyl film, epoxy resin impregnated glass fiber or oil paper insulation and capacitive screens such as aluminum foil or semi-conductive tape are alternately wrapped) to form a low-voltage capacitor 2, and the monitoring terminal is drawn out at the connection point between the capacitor voltage equalizing insulating core 1 and the low-voltage capacitor 2 4. Through the monitoring terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com