Real-time and online error testing and compensating method of rotary table angle measuring system

An online test and compensation method technology, applied in the field of inertial navigation test, can solve the problems that the compensation effect cannot be directly observed online, the accuracy test method lacks timeliness, and the test compensation process is cumbersome, so as to improve the test and compensation efficiency and ensure that it can be monitored , Compensation adjustment accuracy to meet the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

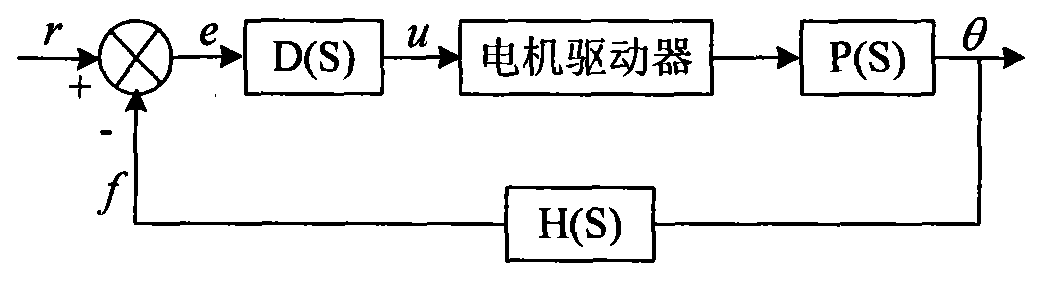

[0040] Example 1: Combining figure 1 A kind of real-time on-line test and compensation method of the error of the turntable angle measurement system based on the circular induction synchronizer of the present invention, the steps are as follows:

[0041] The first step is to test the controller output signal

[0042] Power on the oscilloscope, adjust the scan time interval of the oscilloscope test channel CH1 to 50ms, and the amplitude interval to 50mv, select an appropriate observation point between the controller and the motor driver on the control system hardware circuit to test u(t), and set the oscilloscope to Test this point with the CH1 meter pen, that is, monitor the output signal u(t) of the turntable controller, so that the turntable system starts a closed loop, and the given speed is zero speed. At this time, a DC level close to zero volts can be seen on the oscilloscope.

[0043] The second step is to set the rotation speed of the turntable system

[0044] Select...

Embodiment 2

[0062] Example 2: Combining figure 1 : The present invention is a kind of real-time on-line test and compensation method of the error of the turntable angle measurement system based on the circular induction synchronizer,

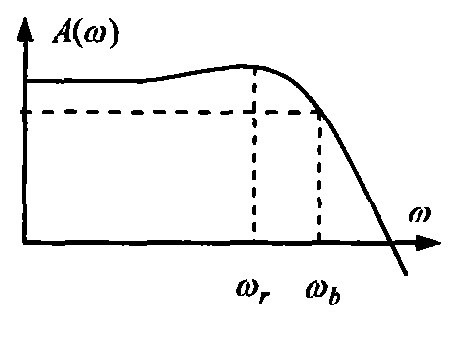

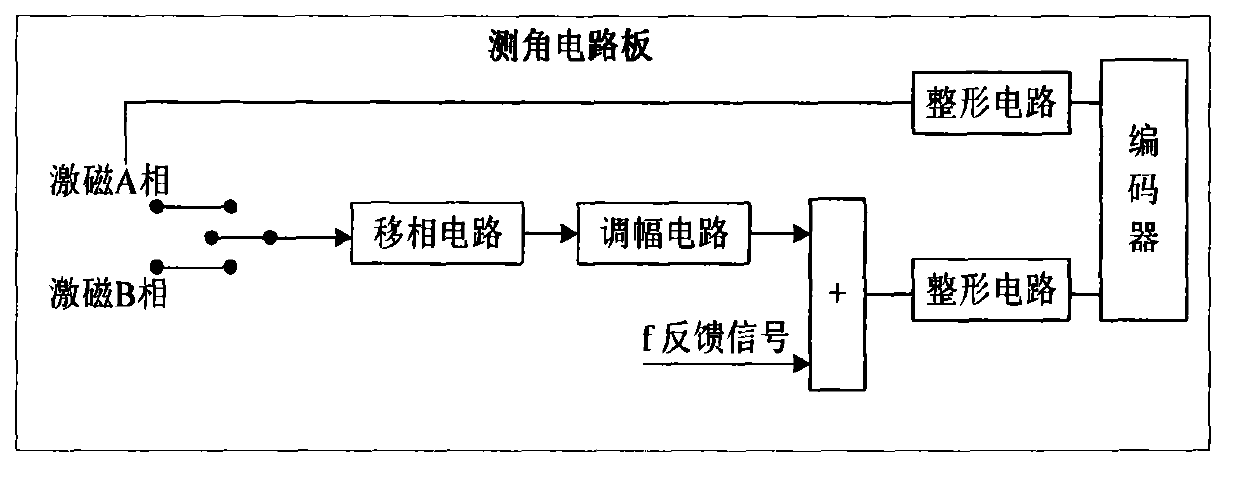

[0063] 1. Principle and method of on-line testing of harmonic error of angle measuring system

[0064] Due to its high precision, simple structure, and strong anti-interference ability, the circular induction synchronizer is widely used as an angle sensor in a high-precision turntable angle measurement system. The circular induction synchronizer adopts two-phase excitation and single-phase output phase detection mode. Due to the signal lead or the amplitude and phase changes of the excitation signal, the angle signal measured at the induction synchronizer pitch will appear as primary and secondary. Harmonic fluctuations, this kind of fluctuation is often called short-period harmonic error, when the turntable system works in closed loop, this harmonic error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com