Susceptor for supporting a semiconductor wafer and method for depositing a layer on a front side of a semiconductor wafer

A semiconductor and deposition layer technology, applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, coatings, etc., to achieve the effect of small radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

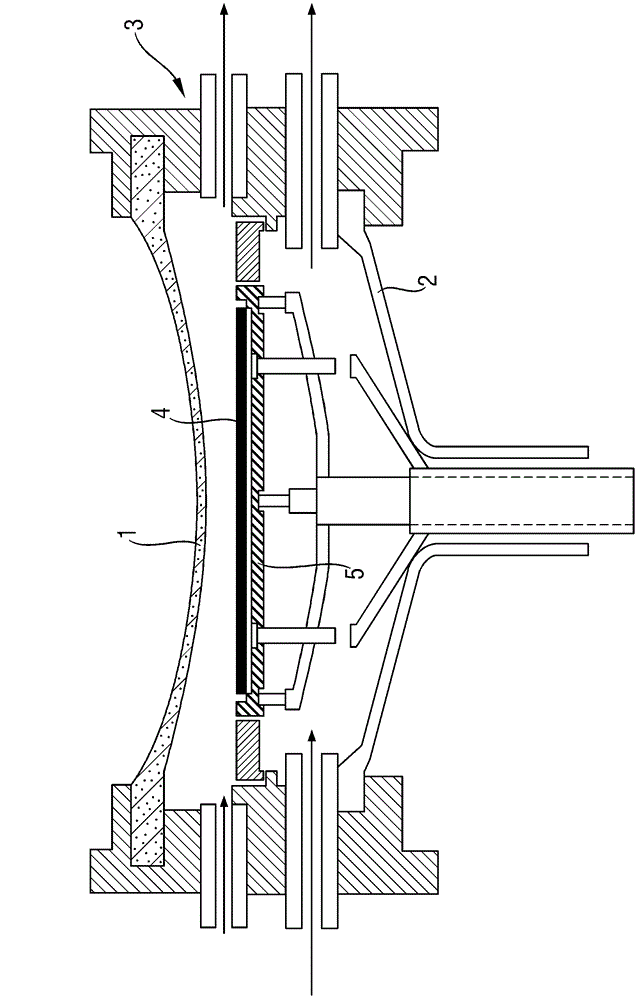

[0028] according to figure 1 The reactor comprises a chamber with an upper dome 1 , a lower dome 2 and side walls 3 . The upper dome 1 and the lower dome 2 are transparent to the thermal radiation emitted by the radiant heating system arranged above and below the chamber. The layer is deposited from the gas phase on the front side of the semiconductor wafer 4 by directing a process gas over the heated semiconductor wafer's front side and in the process reacting with the exposed front side surface to form the layer. Front side refers to the side of the semiconductor wafer on which the layers are deposited. Typically the polished side of a semiconductor wafer. The process gas is fed in through the gas inlet in the side wall of the chamber, and the waste gas remaining after the reaction is discharged through the gas outlet in the side wall of the chamber. Embodiments of chambers with one further gas inlet and one further gas outlet are known. These embodiments are employed, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com