N-type crystalline silicon solar cell and manufacturing method thereof

A technology of a solar cell and a manufacturing method, applied in the field of solar cells, can solve problems such as difficulty in effectively obtaining passivation, and achieve the effects of good passivation effect, reduction in number, and reduction in defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

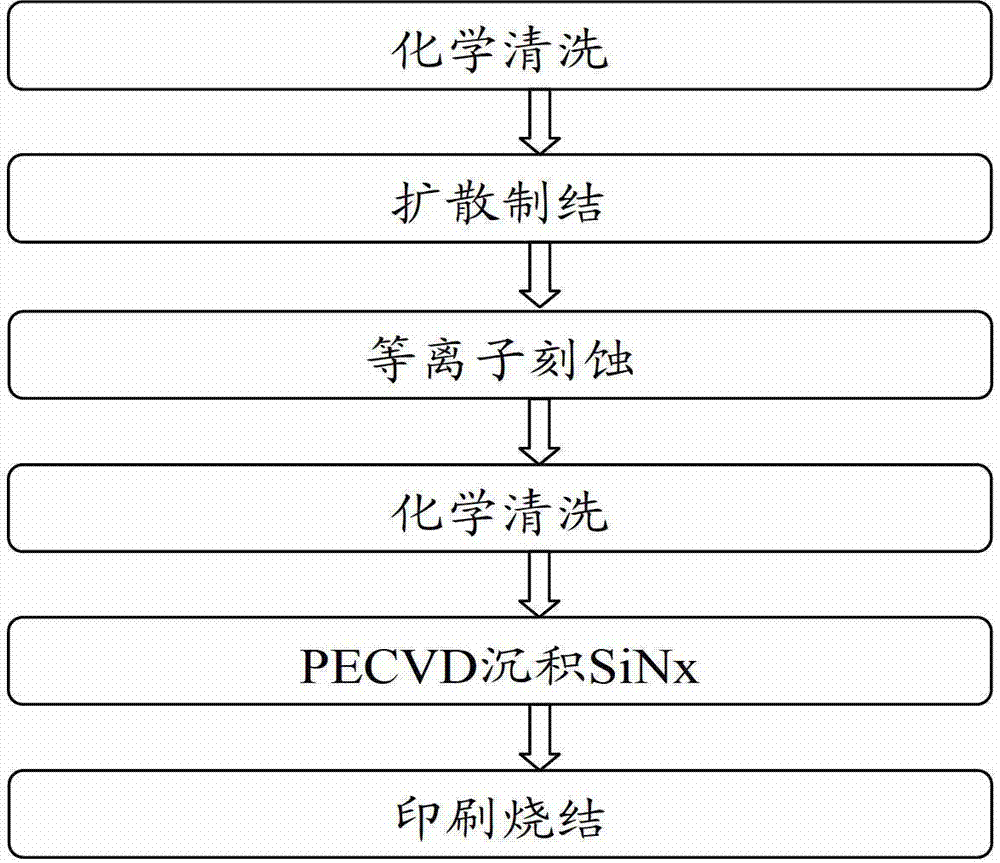

Method used

Image

Examples

preparation example Construction

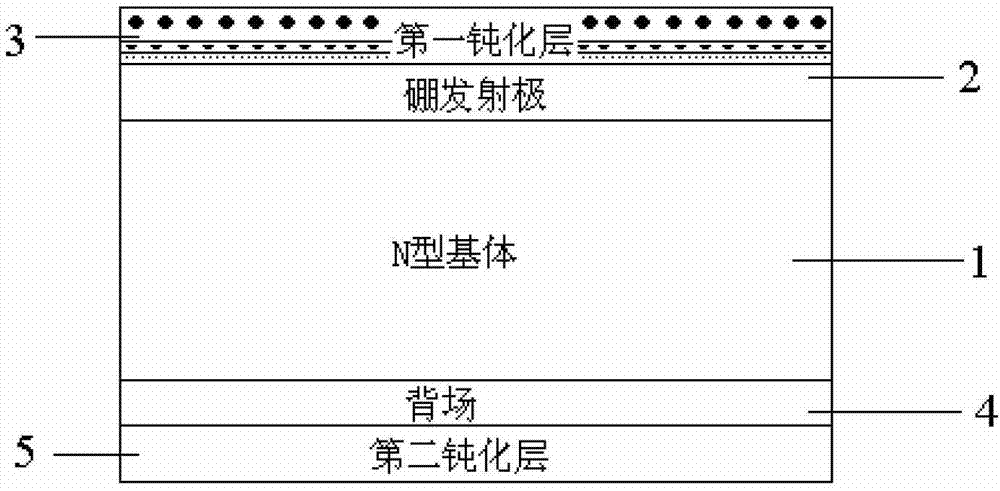

[0031] In order to simplify the preparation method of the aluminum oxide film, preferably step S22 also includes in the process of forming aluminum oxide, after placing the backs of any two N-type substrates prepared with silicon oxide films close to each other, place the silicon oxide film away from the boron emitter Aluminum oxide film is formed on the surface. Since the aluminum oxide film is only formed on the outer surface of the silicon oxide film on the boron emitter, any two N-type substrates are placed back to back when preparing the aluminum oxide film, and the aluminum oxide film is only formed on the front of the N-type substrate , thus simplifying the preparation method of aluminum oxide film.

[0032] Preferably, there is also a silicon nitride film on the outside of the silicon oxide film on the back surface of the N-type substrate of the present invention, and then the manufacturing method also includes separating the silicon oxide film on the surface of the ba...

Embodiment 1

[0036] Preparation of N-type crystalline silicon solar cells:

[0037] A boron emitter is formed on the front of the silicon substrate through boron diffusion to obtain a silicon wafer with a p-n junction. First, a silicon oxide film with a thickness of about 5 nm is prepared on both sides of the silicon wafer with a p-n junction by magnetron sputtering. , in which the silicon oxide film is evenly distributed on the front and back surfaces of the silicon wafer; then, an ultra-thin aluminum oxide film with a thickness of about 3nm is deposited on the silicon oxide film on the boron emitting surface by thermal atomic layer deposition, During the deposition process, the silicon wafers are placed back to back, so that the aluminum oxide film is only deposited on the boron emitter; finally, the PECVD method is used to deposit the silicon nitride film, in which the silicon nitride film is deposited on both the front and back surfaces of the silicon wafer. The thickness of the silico...

Embodiment 2

[0040] A boron emitter is formed on the front of the silicon substrate through boron diffusion to obtain a silicon wafer with a p-n junction. First, a silicon oxide film with a thickness of about 3 nm is prepared on both sides of the silicon wafer with a p-n junction by thermal oxidation. The silicon oxide film is evenly distributed on the front and back surfaces of the silicon wafer; then PECVD is used to deposit aluminum oxide film with a thickness of about 7nm on the silicon oxide film on the boron emission surface; finally, the PECVD method is used to deposit A silicon nitride film is formed, wherein the silicon nitride film is deposited on the front and back surfaces of the silicon wafer, the thickness of the front silicon nitride film is about 80nm, and the thickness of the back silicon nitride film is about 70nm.

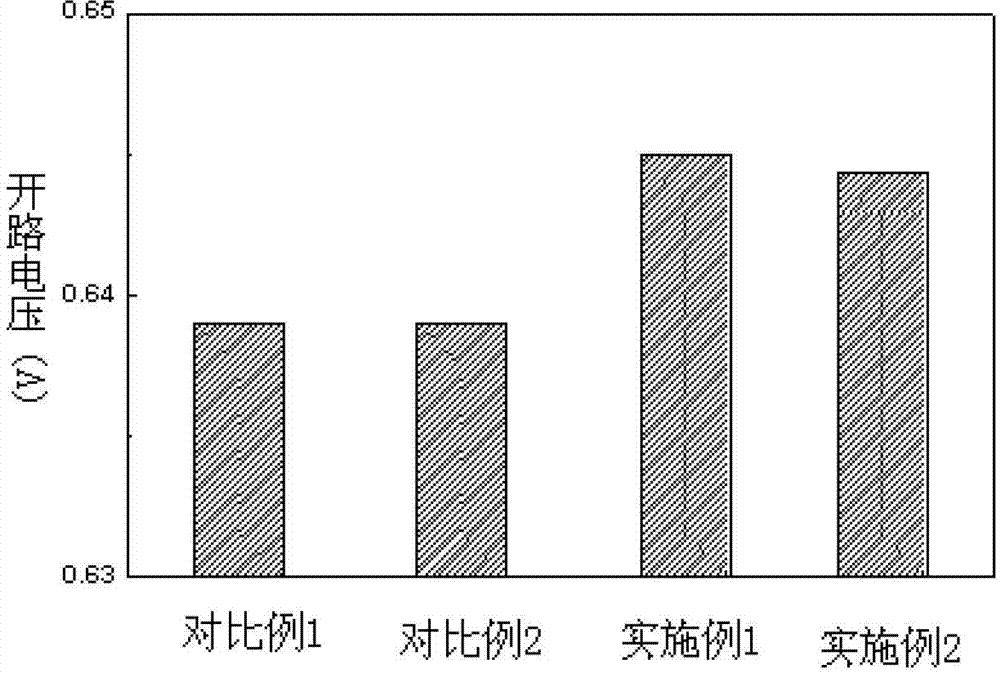

[0041] Test the open circuit voltage of the above-mentioned N-type crystalline silicon solar cell, the results are as attached image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com