Solar cell provided with amorphous silicon passivation layer and manufacturing method of solar cell

A technology for solar cells and amorphous silicon layers, applied in the field of solar cells, can solve problems such as poor surface passivation effect and poor cell conversion efficiency, and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

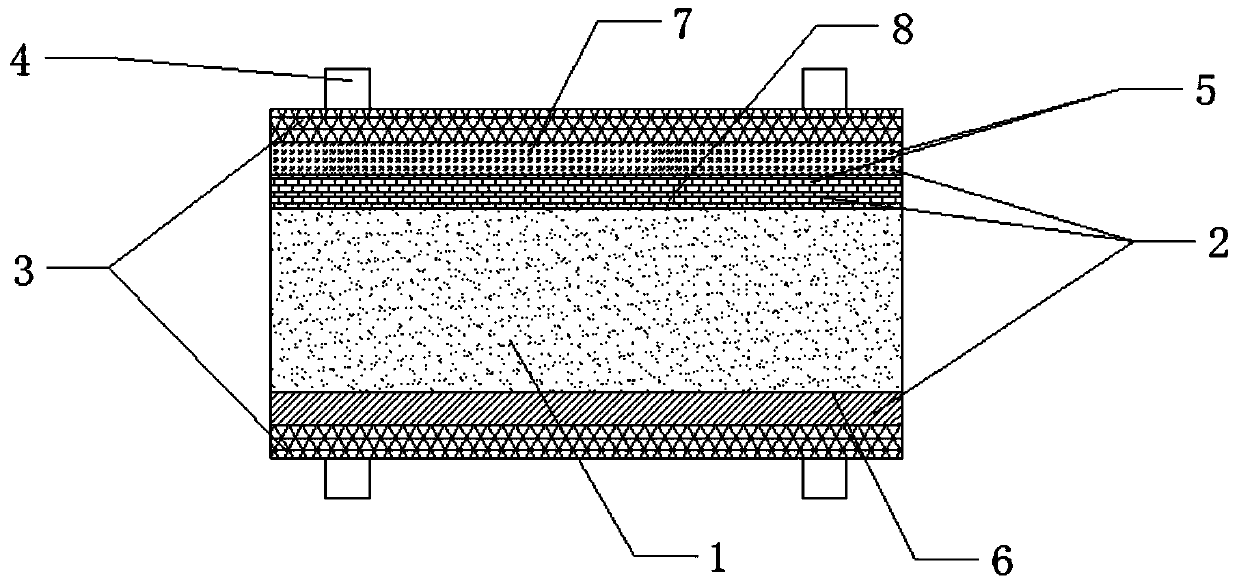

[0038]A solar cell using an amorphous silicon passivation layer, comprising a base layer 1, an amorphous silicon layer 2 arranged on the upper and lower sides of the base layer 1, a transparent conductive oxide layer 3 arranged on the outer surface of the amorphous silicon layer 2, and a The metal electrode 4 on the outer surface of the transparent conductive oxide layer 3; the base layer 1 is a P-type single crystal silicon wafer, and the amorphous silicon layer 2 includes the first N-type silicon wafers arranged in sequence along the upper and lower surfaces of the P-type single crystal silicon wafer. A doped layer 5, a first P-type doped layer 6, the first N-type doped layer 5 includes an N+-a-Si doped layer 7 and an N-c-Si doped layer 8 arranged in sequence from top to bottom, The first P-type doped layer 6 is a P+-a-Si doped layer; a P-type doped and N-type doped amorphous silicon layer is used as a passivation coating to form an N+-a- The step change structure of Si / N-c-...

Embodiment 2

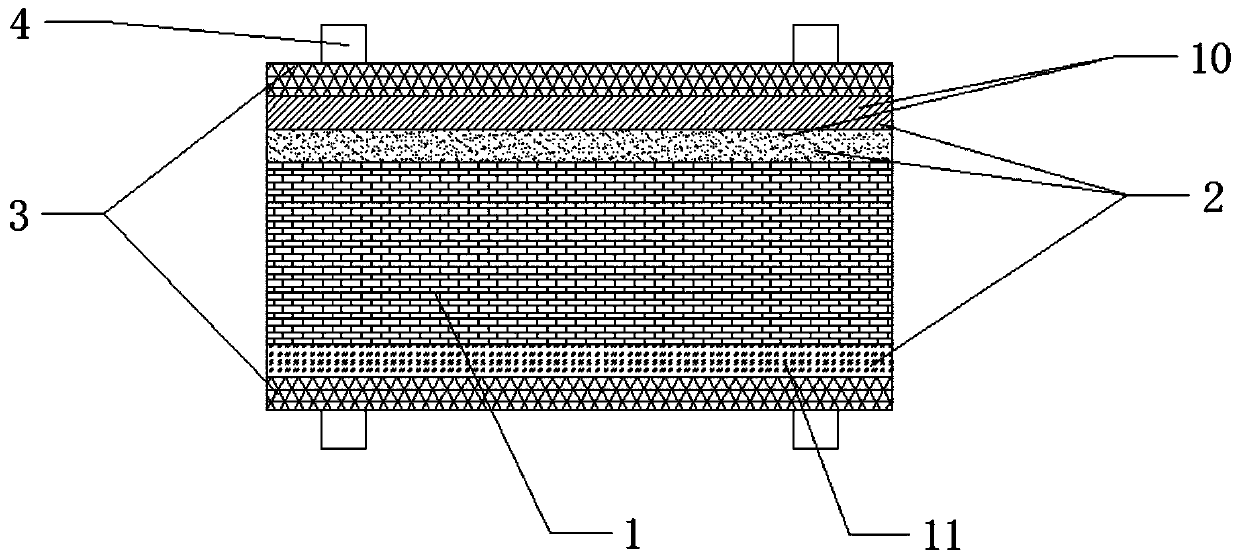

[0040] On the basis of Example 1, the base layer 1 is an N-type monocrystalline silicon wafer, and the amorphous silicon layer 2 includes a second P-type doped layer 10 arranged sequentially along the upper and lower surfaces of the N-type monocrystalline silicon wafer, The second N-type doped layer 11, the second P-type doped layer 10 includes a P+-a-Si doped layer and a P-c-Si doped layer arranged in sequence from top to bottom, and the second N-type doped layer The impurity layer is N+-a-Si doped layer.

Embodiment 3

[0042] On the basis of embodiment 2, both the N+-a-Si doped layer and the P+-a-Si doped layer are hydrogenation-doped amorphous silicon layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com