Optical fiber coiling device

An optical fiber coiling and optical fiber technology, which is applied in the field of optical fiber devices, can solve the problems of small bending radius, deterioration of laser performance, and brittle fiber texture, and achieve the effect of reducing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

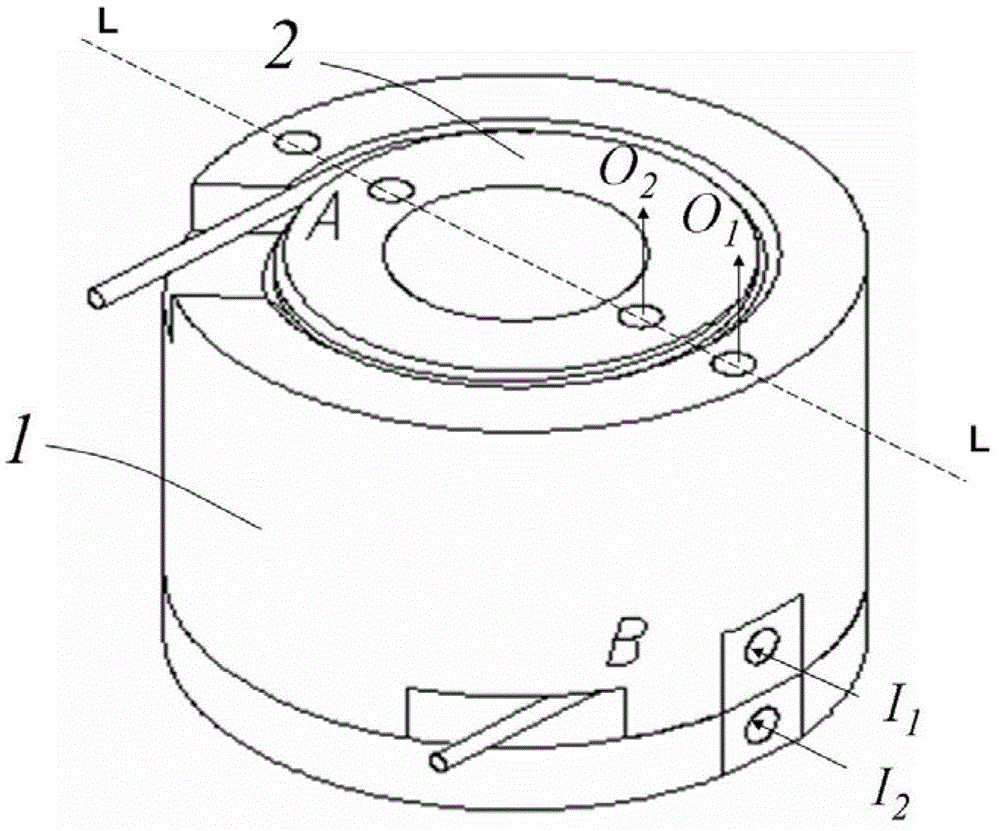

[0025] According to one embodiment of the present invention, an optical fiber coiling device is provided, the three-dimensional structure of which is as follows figure 1 As shown, the optical fiber coiling device includes an inner cylinder 2 and an outer cylinder 1 .

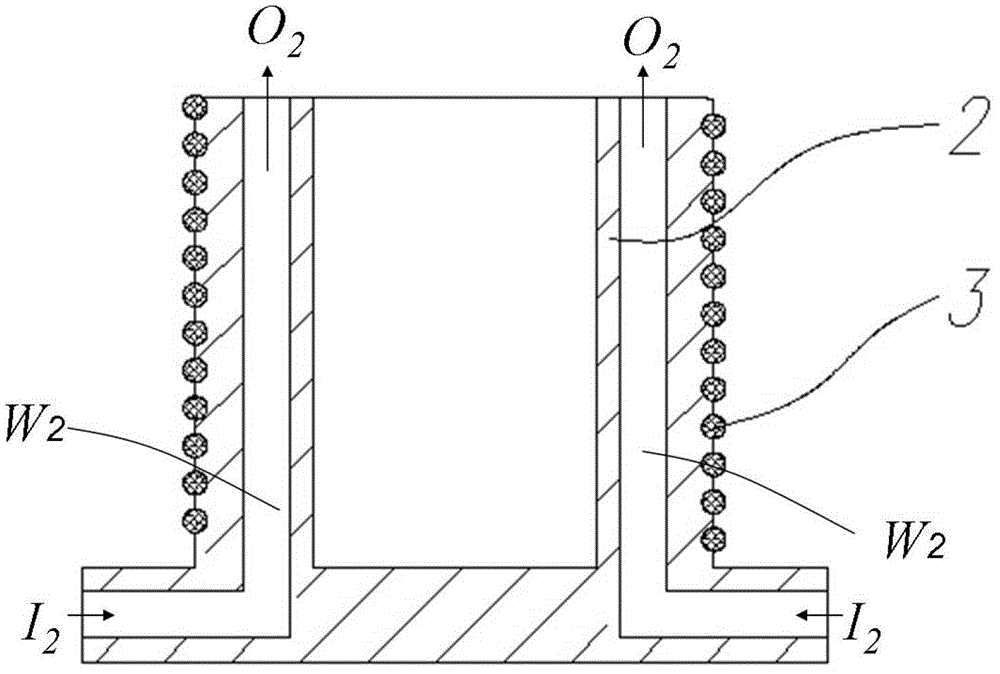

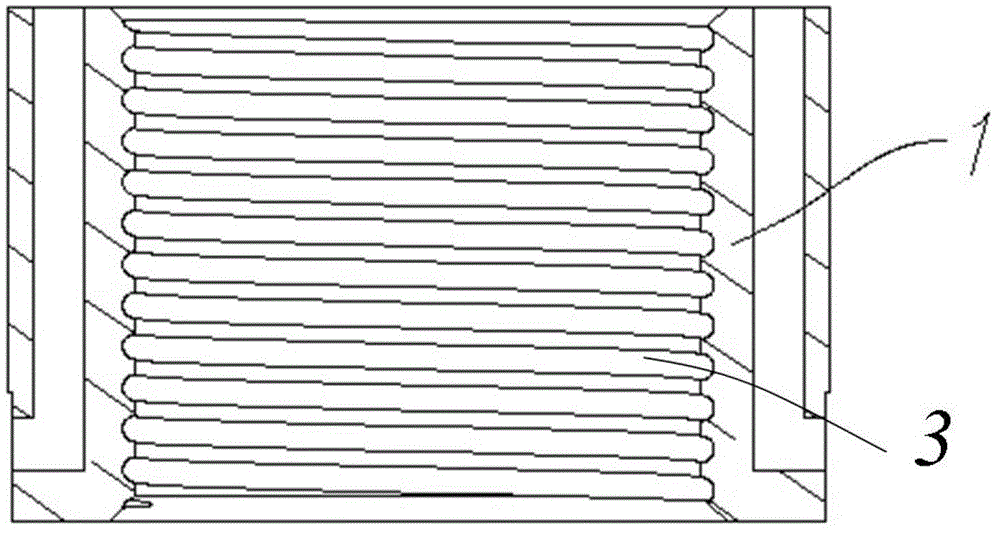

[0026] Wherein the structure of inner cylinder 2 is as figure 2 As shown, it is cylindrical and made of metal material. There is a spiral groove on its outer cylindrical surface for accommodating the optical fiber 3, wherein the cross section of the spiral groove is semicircular, and its diameter is the same as that of the optical fiber. 3 have the same diameter, the three-dimensional view of the structure of the inner tube 2 after the optical fiber 3 is accommodated is as follows image 3 as shown, image 3 It is a schematic cross-sectional view of the outer cylinder after being cut. It can be seen from the figure that the optical fiber 3 is accommodated in the semicircular groove on the inner cylinder, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com