Neutralisation of gaseous contaminants by means of artificial photosynthesis

A technology of artificial photosynthesis and gas, which is applied in the direction of gas treatment, use of liquid separation agent, chemical/physical/physicochemical process of energy application, etc., can solve the problem of expensive initial investment and maintenance cost

Inactive Publication Date: 2012-10-24

MASTERIDEA

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For those systems capable of capturing 99% of particulate matter, the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

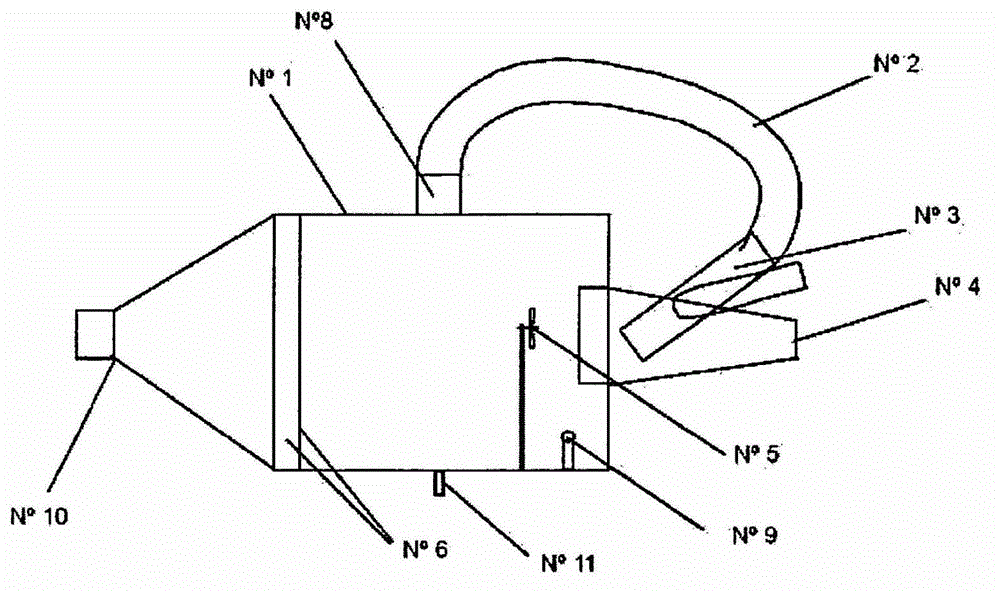

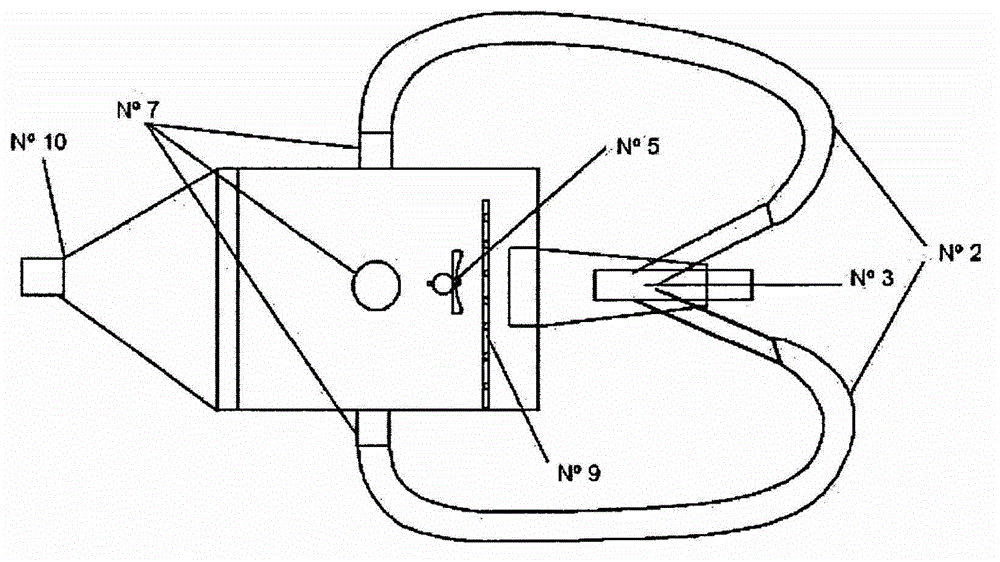

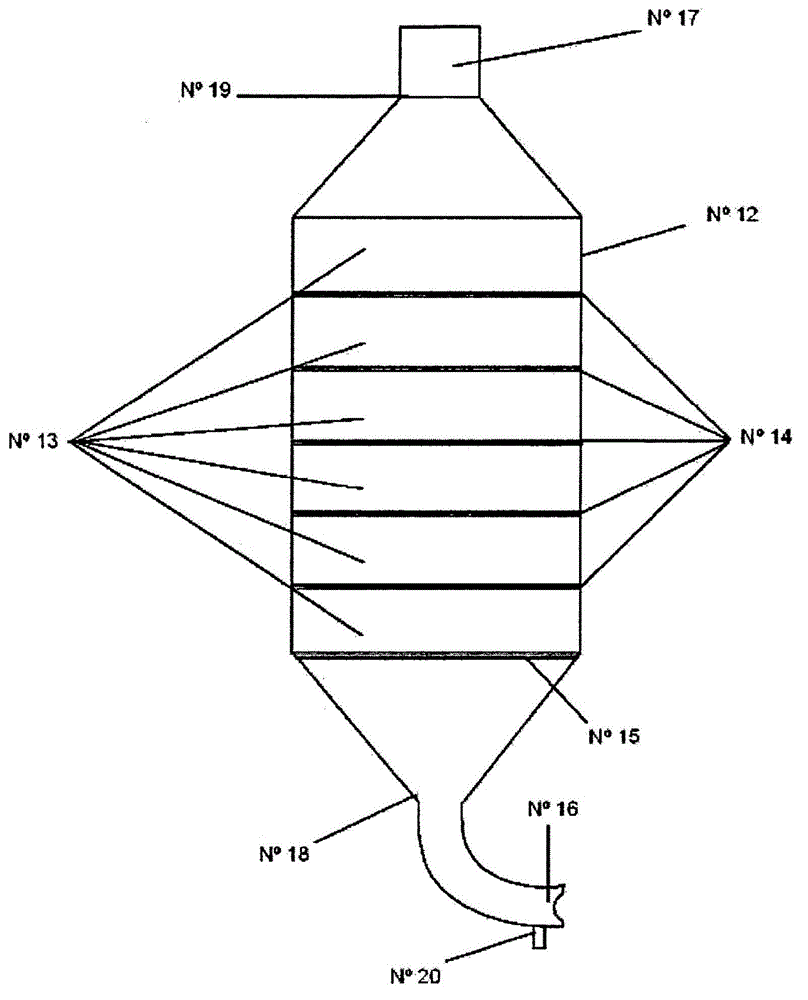

The invention relates to an artificial photosynthesis system and process used to neutralise harmful elements from any type of combustion, reducing the volume and initial pressure of the gases, by means of the kinetic energy produced by the accelerated recirculation of the gases according to the principle of molecular resonance or gas resonance, in order to then release oxygen and innocuous liquid substances by means of physical and chemical processes. Said system comprises a main chamber provided with a main gas inlet and a gas outflow tube, the main chamber comprising: a tube with nozzles arranged in the lower part of the main chamber enabling the passage of steam in the form of a steam curtain; a propeller; flexible tubes that protrude from the main chamber and connect to the main gas inlet; an electric motor for gas extraction, enabling the pressurised inflow of the gases towards the flexible tube; an evacuation duct connecting the main chamber to a secondary chamber that comprises an inlet tube for the gases from the main chamber and a gas outflow duct arranged in the upper end of the secondary chamber, the secondary chamber comprising: a plurality of connected units of plastic foam comprising a perforated sheet of aluminium at the connection points of each unit; a high-power centrifuge extractor outside the upper end of the secondary chamber; and tubes for ejecting the liquid residues, arranged in the lower part of the primary chamber and the secondary chamber.

Description

technical field [0001] The present invention relates to a system and method for neutralizing gaseous pollutants by an artificial photosynthesis autonomous system called "SAFA". Background technique [0002] It is useful to consider some technical and historical aspects of the problem of environmental pollution. The greenhouse effect is the best reference. [0003] Throughout this century, and with further global industrialization, we have witnessed a global environmental catastrophe with high levels of pollutants from the industrialization process, humans and their derivatives such as transportation and other mobile sources. The foregoing has increased the natural concentration of gases in the atmosphere, and has increased gases with higher toxicity than those that occur naturally. Among these gases, carbon monoxide (CO), carbon dioxide (CO 2 ), chlorofluorocarbons (CFCs), methane (CH 4 ), and nitrous oxide (N 2 o). [0004] The prior art relates to systems or methods ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D47/06

CPCB01D2257/404B01D2257/504B01D2257/302Y02C10/04B01D53/24B01D53/50B01D53/62B01D2257/502B01D2258/0283B01D53/56Y02C20/40Y02P20/151B01D47/06B01D53/00B01D53/34B01J19/08

Inventor 路易斯·文森特·冈萨雷斯·波塔莱斯让·保罗·奥利格尔·冈萨雷斯

Owner MASTERIDEA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com