Full automatic ring mounting machine

A fully automatic, ring-mounting technology, applied in the field of machining, can solve the problems of complex structure, high cost, low precision and accuracy, and achieve the effect of reducing investment cost, improving precision and accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

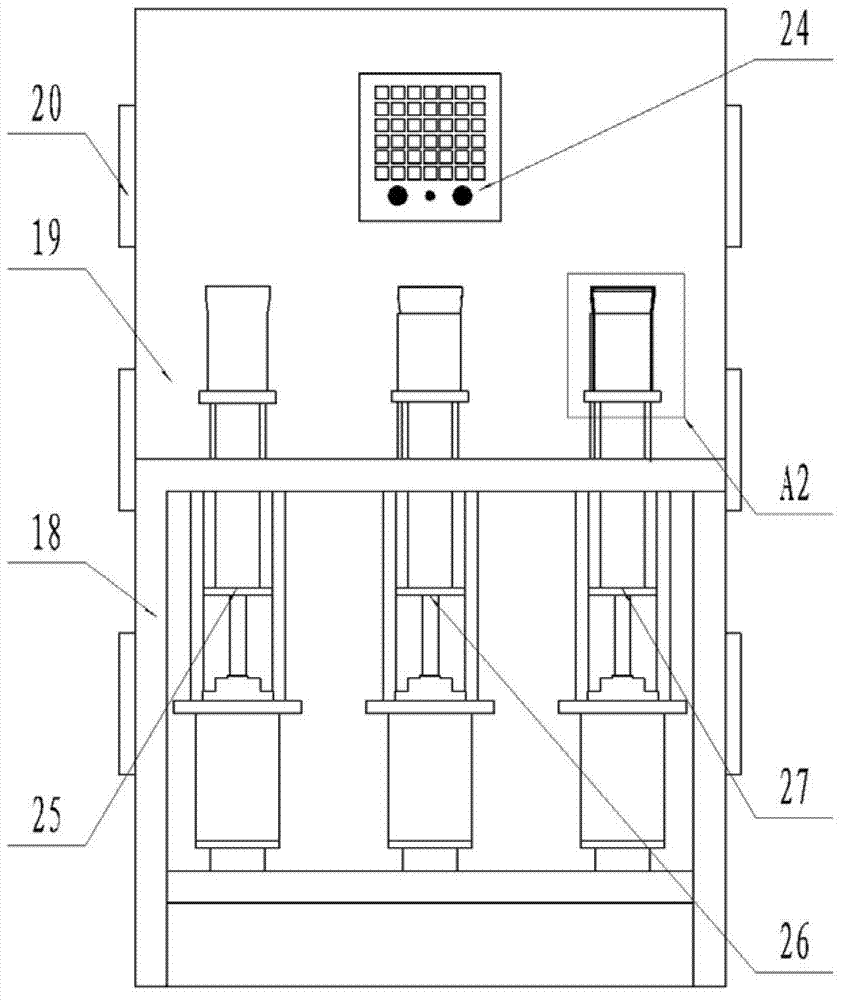

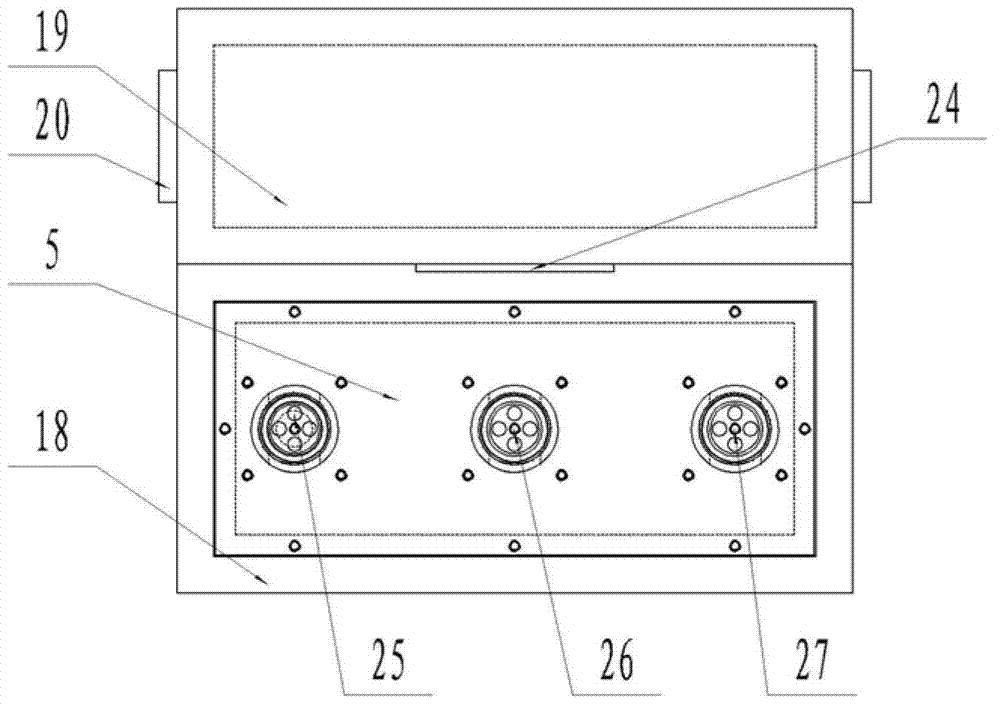

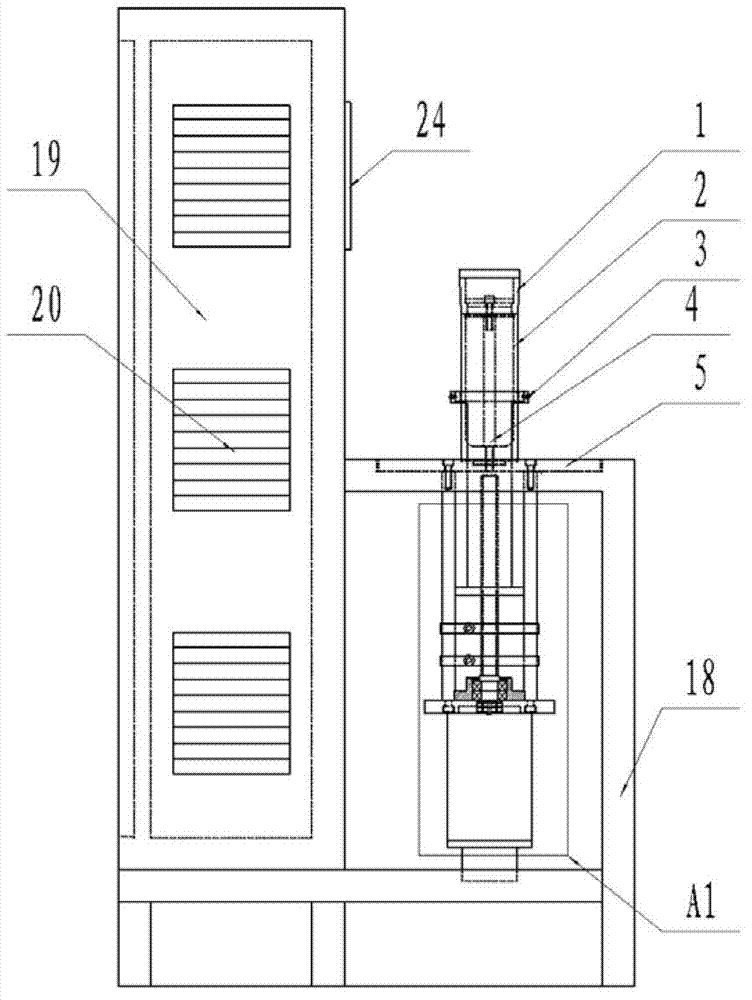

[0023] A fully automatic ring-fitting machine, comprising a frame 18, on which a worktable 5 and a numerically controlled distribution box 19 with a three-axis numerically controlled touch screen 24 and heat dissipation windows 20 are arranged, on which the workbench 5 An oil ring groove assembly unit 25, a second air ring assembly unit 26 and a first air ring assembly unit 27 are installed; each assembly unit includes a servo motor 16 and a ball screw 9, and the ball screw 9 is externally provided with Push ring sleeve 3, the bottom of the push ring sleeve 3 is provided with a ball screw nut 8; the top of the ball screw 9 is equipped with a ring sleeve 2 and a ring sleeve stop 1 through the fastening screw 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com