Pressing die device for manufacturing fireworks outer cylinder and process method thereof

A compression molding device and outer cylinder technology, which is applied in packaging, transportation and packaging, envelope/bag manufacturing machinery, etc., can solve the problem that paper cannon barrels are easy to be soaked by rain, and the occurrence of explosion, loose and inverted cylinders, and cannon The problem of moisture in the barrel and lead wires is eliminated, and the effects of easy automatic control, reduced failure, and convenient operation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Before further describing the present invention, it should be understood that the present invention is not limited to the following specific embodiments of the invention. At the same time, it should also be understood that the terminology used herein is only used to describe specific implementations, rather than to limit the present invention.

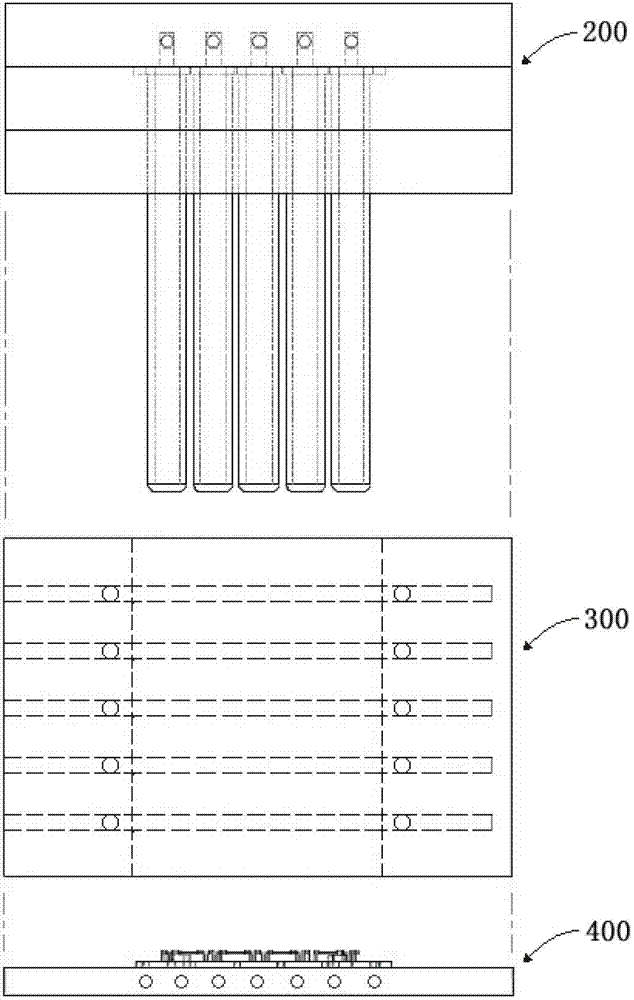

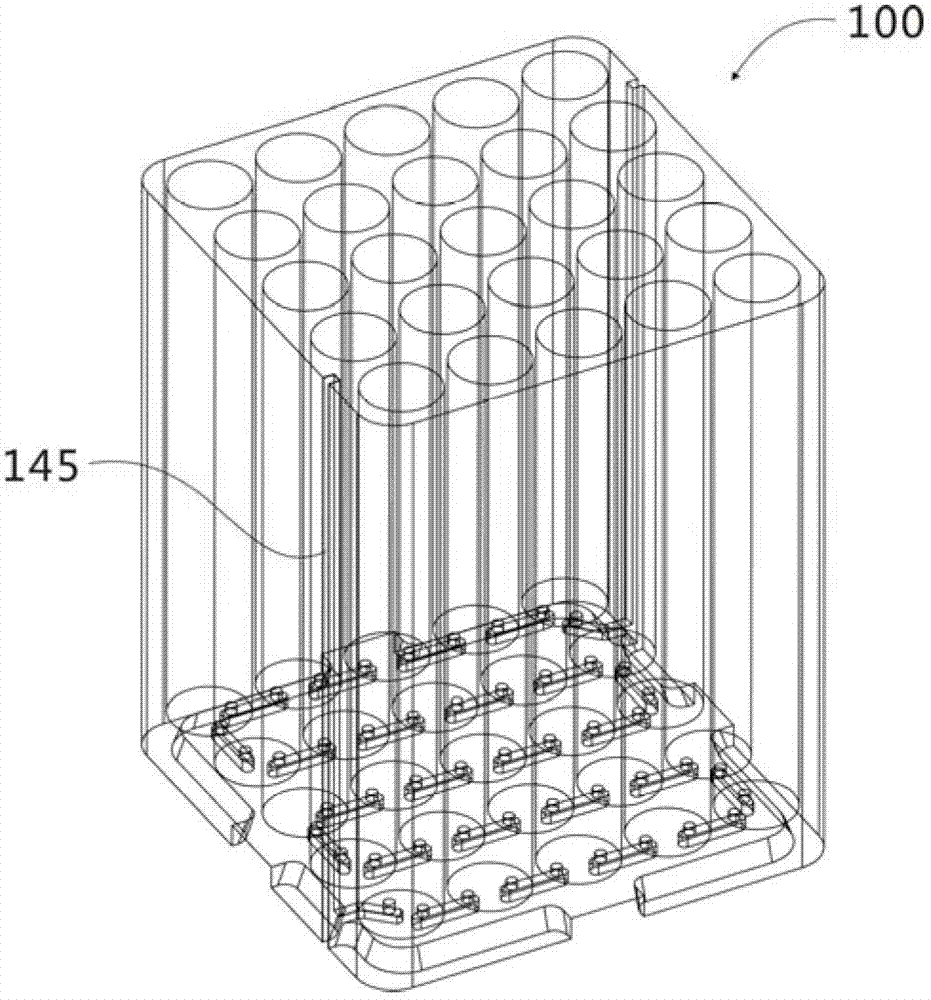

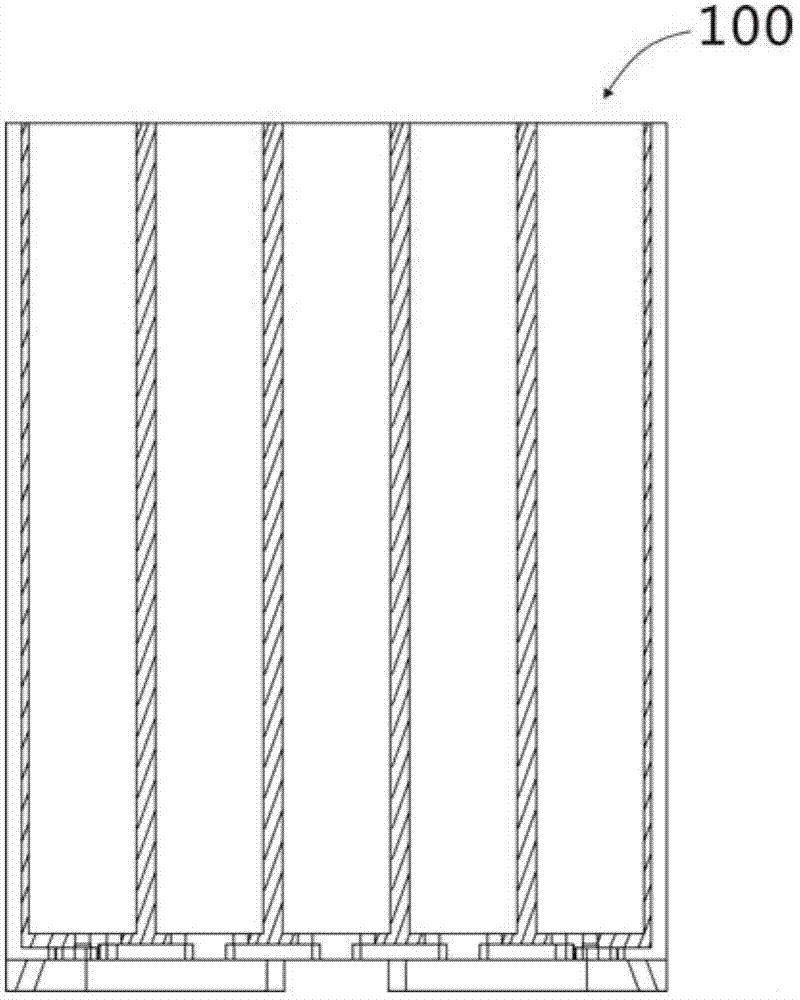

[0036] In one embodiment of the present invention, for preparing salute outer cylinder ( Figures 2A-2C ) of the compression molding device ( figure 1 )include:

[0037] Upper die 200 ( Figures 3A-6B), which includes a first template 210, a second template 220, a third template 230 and a plurality of column tubes 240 each with a closed end and an open end, wherein the second template 220 and the first template 210 are superimposed on each other , and the second template 220 has a plurality of second template perforations, which are arranged in a corresponding relationship with the plurality of column tubes 240, so that each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com